When it comes to maintaining and repairing a cleaning machine, knowing the layout and functions of each individual component is crucial. Whether you’re dealing with a malfunction or performing regular upkeep, having a clear guide to the internal structure of the device can save both time and effort.

By examining a detailed schematic of your vacuum, you can identify which sections are responsible for specific tasks and understand how they interact. This insight not only helps with troubleshooting issues but also empowers you to perform repairs with confidence, ensuring a longer lifespan for your equipment.

Familiarizing yourself with these key components and their relationships to each other can make a world of difference in the efficiency of your machine. Whether you’re replacing a worn-out part or fine-tuning performance, a well-organized overview is essential.

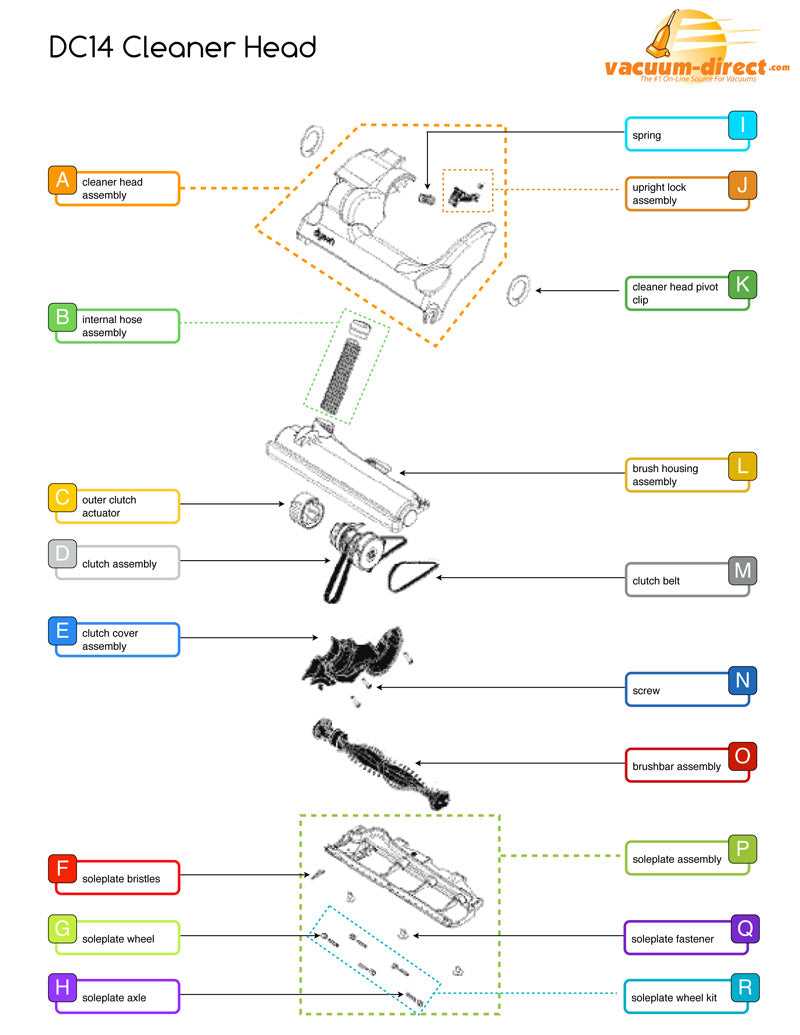

Understanding the Vacuum Cleaner Components

To effectively maintain and troubleshoot your cleaning device, it’s essential to understand the key components that make up its design. Each part has a specific function that contributes to the overall performance, and recognizing how these elements interact can significantly improve your repair and maintenance experience.

Main Functional Areas

The machine is built around several core functional areas. Each area works in tandem to ensure optimal performance and longevity of the appliance. The main functional sections include:

- Motor Unit: This part drives the suction and is the heart of the machine’s cleaning power.

- Filtration System: Filters dirt, dust, and allergens from the air, ensuring clean exhaust.

- Brush Bar: A crucial element for agitating carpets and removing debris.

- Power Switch and Controls: Where the user interacts with the device to adjust settings and activate functions.

Key Supportive Components

In addition to the primary areas, there are several supporting elements that help maintain the functionality of the machine. These parts may not be as visible but are essential for smooth operation:

- Wheels and Axles: Allow for easy movement and maneuverability.

- Dustbin or Collection Tank: Stores collected debris until it is emptied.

- Hoses and Attachments: Provide flexibility for different cleaning tasks and reach.

Understanding the relationships between these various parts will help you make informed decisions about maintenance and repairs, ensuring your cleaning device continues to perform effectively for years.

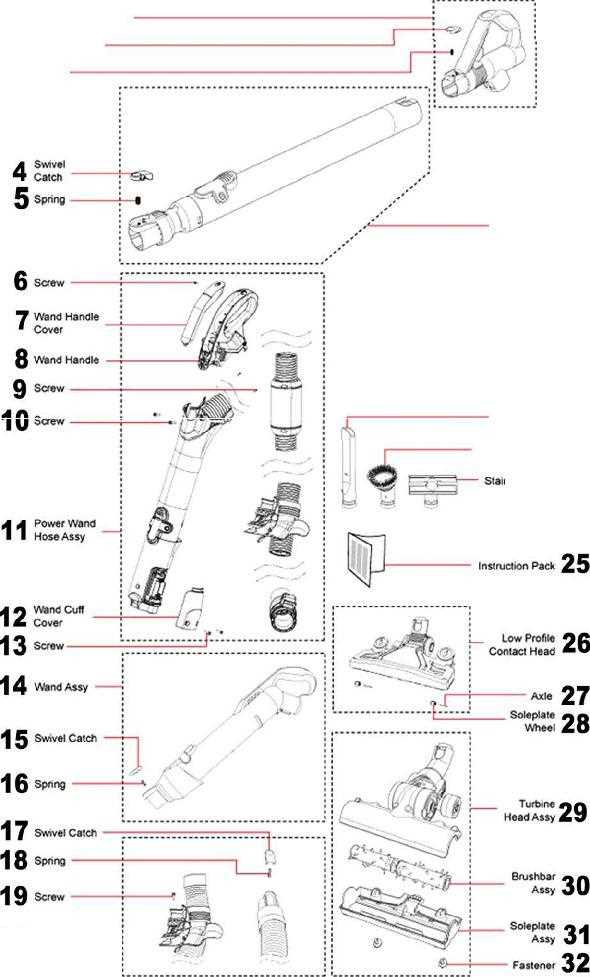

How to Use the Schematic Effectively

Utilizing a detailed schematic of your cleaning device can streamline the repair and maintenance process. By clearly visualizing the layout of the various components, you can quickly identify and address any issues that may arise, ensuring that your equipment operates at peak efficiency.

Start by carefully studying the schematic and understanding the relationships between each part. This will allow you to recognize how components interact and where potential problems might occur. With a solid grasp of the overall structure, you can easily pinpoint areas that require attention.

Step-by-Step Guide

Follow these steps to make the most of the schematic:

- Locate the section you’re working on: Focus on the area where repairs or replacements are needed. This helps narrow down your search and makes the process more efficient.

- Identify the component’s role: Understand what each part does and how it contributes to the overall function. This can guide you in diagnosing issues.

- Check for part numbers: Use the schematic to find specific part numbers for replacements. This ensures compatibility and reduces the risk of purchasing incorrect items.

- Follow assembly instructions: When reassembling the machine, use the schematic to confirm the correct order and orientation of parts to avoid mistakes.

Maximize the Benefits

To further enhance your repair experience, refer to the schematic regularly during the disassembly and reassembly process. With a clear visual reference, the likelihood of missing a step or overlooking a critical component is minimized, leading to a smoother and more accurate repair session.

Common Issues and Repair Tips for Vacuum Cleaners

Like any mechanical device, vacuum cleaners can experience a variety of issues over time. Understanding common problems and knowing how to address them can help extend the life of your equipment and ensure optimal performance. Regular maintenance and timely repairs are key to keeping your machine running smoothly.

Some frequent issues include a loss of suction, unusual noises, and poor brush bar performance. Identifying the cause of these problems is often straightforward with a little troubleshooting. Below are some of the most common concerns and practical solutions.

Loss of Suction

If the vacuum loses suction, it often indicates a blockage or an issue with the filtration system. To resolve this:

- Check for clogs: Inspect hoses and airways for blockages. Remove any debris that may be obstructing airflow.

- Clean filters: Over time, filters can become clogged with dust. Clean or replace them as needed to restore suction power.

- Examine the brush bar: Ensure that the brush bar is free from tangled hair or debris, as this can reduce suction efficiency.

Unusual Noises

If your vacuum begins to make strange noises, it could be a sign of a malfunctioning motor, clogged brush bar, or loose parts. Here’s what you can do:

- Inspect the motor: If the motor is making a high-pitched sound or buzzing, it might need servicing or replacement.

- Check the brush bar: Remove any tangled fibers or debris around the brush bar, as this can cause unusual noise during operation.

- Tighten loose components: Ensure all parts, including the hose and any attachments, are securely fastened to prevent rattling sounds.

Poor Brush Bar Performance

If the brush bar is not rotating correctly or is ineffective at agitating the carpet, it may be obstructed or worn out. To fix this:

- Clear debris: Remove any hair or fibers that may have wrapped around the brush bar.

- Check the motor belt: The motor belt that drives the brush bar can wear out over time. Replace it if necessary.

- Inspect for damage: If the brush bar itself is damaged, it may need to be replaced to restore proper function.

By staying vigilant for these common issues and addressing them promptly, you can keep your vacuum cleaner in excellent working condition and avoid costly repairs down the road.