Efficient farming equipment plays a crucial role in modern agriculture, enabling farmers to complete essential tasks with precision and speed. Familiarity with the internal components of these machines is vital for maintaining their performance and ensuring long-term reliability. Knowing how the different elements work together can significantly impact the overall efficiency of the machine.

For optimal operation, it is important to have a clear understanding of the key mechanical features involved in the process. This knowledge allows for better maintenance, quick troubleshooting, and smooth adjustments when necessary. Recognizing the various parts that work in tandem within the system ensures minimal downtime and improved productivity.

Regular upkeep and an understanding of the assembly help prevent costly repairs and enhance the life expectancy of the equipment. By learning how each component contributes to the machine’s performance, operators can make more informed decisions, ultimately leading to more successful operations.

Understanding the Agricultural Machine

Farming equipment designed for hay and forage collection plays a critical role in ensuring smooth operations on a farm. These machines are engineered to perform a variety of tasks, such as gathering, compressing, and binding harvested materials. By breaking down the process and understanding the mechanics behind it, farmers can achieve higher efficiency and reduce the likelihood of technical failures.

How the System Operates

At the heart of this equipment lies a combination of mechanisms that work together seamlessly. The machine uses a series of moving parts that allow for the collection and shaping of the harvested material. Understanding how each part interacts within the larger system helps operators maintain optimal performance and address potential issues before they arise.

Key Features for Effective Use

Maintaining the machine’s operational health is crucial for ensuring continuous productivity. With regular attention to its components, users can achieve maximum efficiency during the harvesting process. The key features include an efficient compression system and reliable binding components, both critical to ensuring that the final output meets the desired quality standards.

Key Components in the Agricultural Equipment

Understanding the core elements of farming machinery is essential for maximizing performance and ensuring longevity. The functionality of these systems relies on various interconnected parts that facilitate smooth operation during harvesting tasks. Each component has a specific role, contributing to the overall efficiency of the machine.

Mechanical Systems and Their Functions

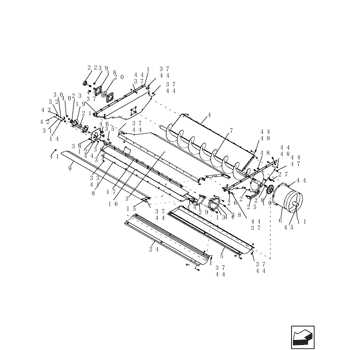

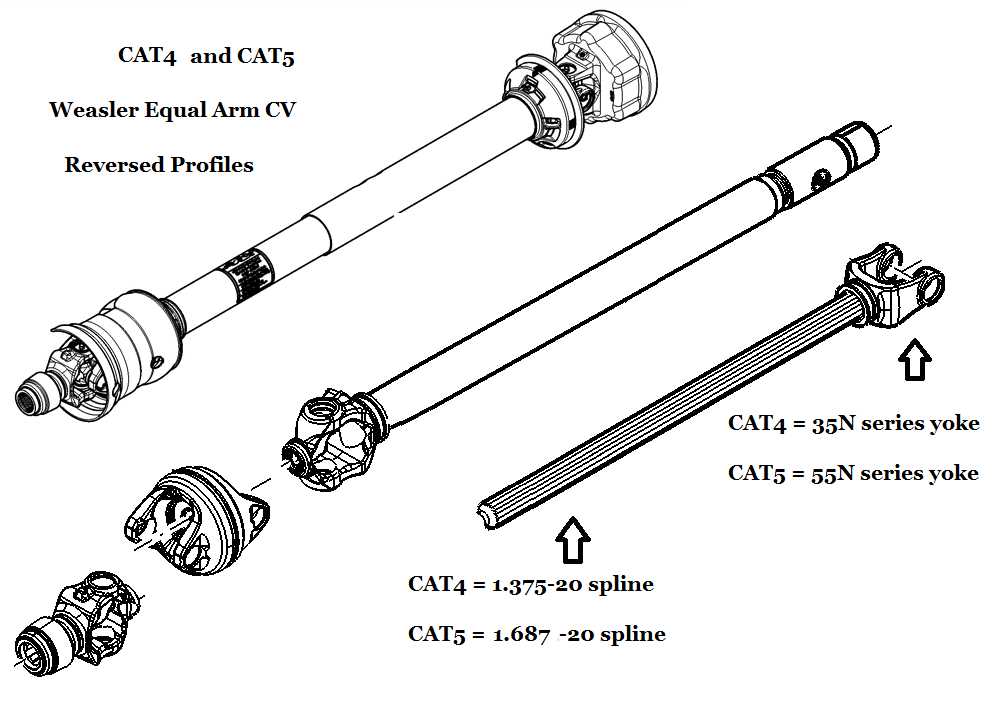

The primary mechanical systems include elements responsible for collecting, compressing, and binding the harvested material. These systems are designed to work in unison to ensure a continuous and reliable workflow. Key parts such as the intake mechanism, compression chamber, and binding system each play a vital role in achieving the machine’s purpose.

Efficient Movement and Control

Movement is another critical aspect of these machines, with various moving parts working together to transport and manipulate the material. The drive system, powered by the engine, controls the speed and operation of these components. By understanding how the movement systems interact with other components, operators can ensure smoother functionality and address issues more effectively.

Maintenance Tips for Agricultural Equipment

Proper upkeep of farming machinery is essential for ensuring reliable performance and extending its lifespan. Regular maintenance not only helps avoid unexpected breakdowns but also contributes to the machine’s efficiency, allowing it to function optimally throughout its operational life. Knowing the best practices for care and maintenance can save both time and money in the long run.

Routine Inspections and Adjustments

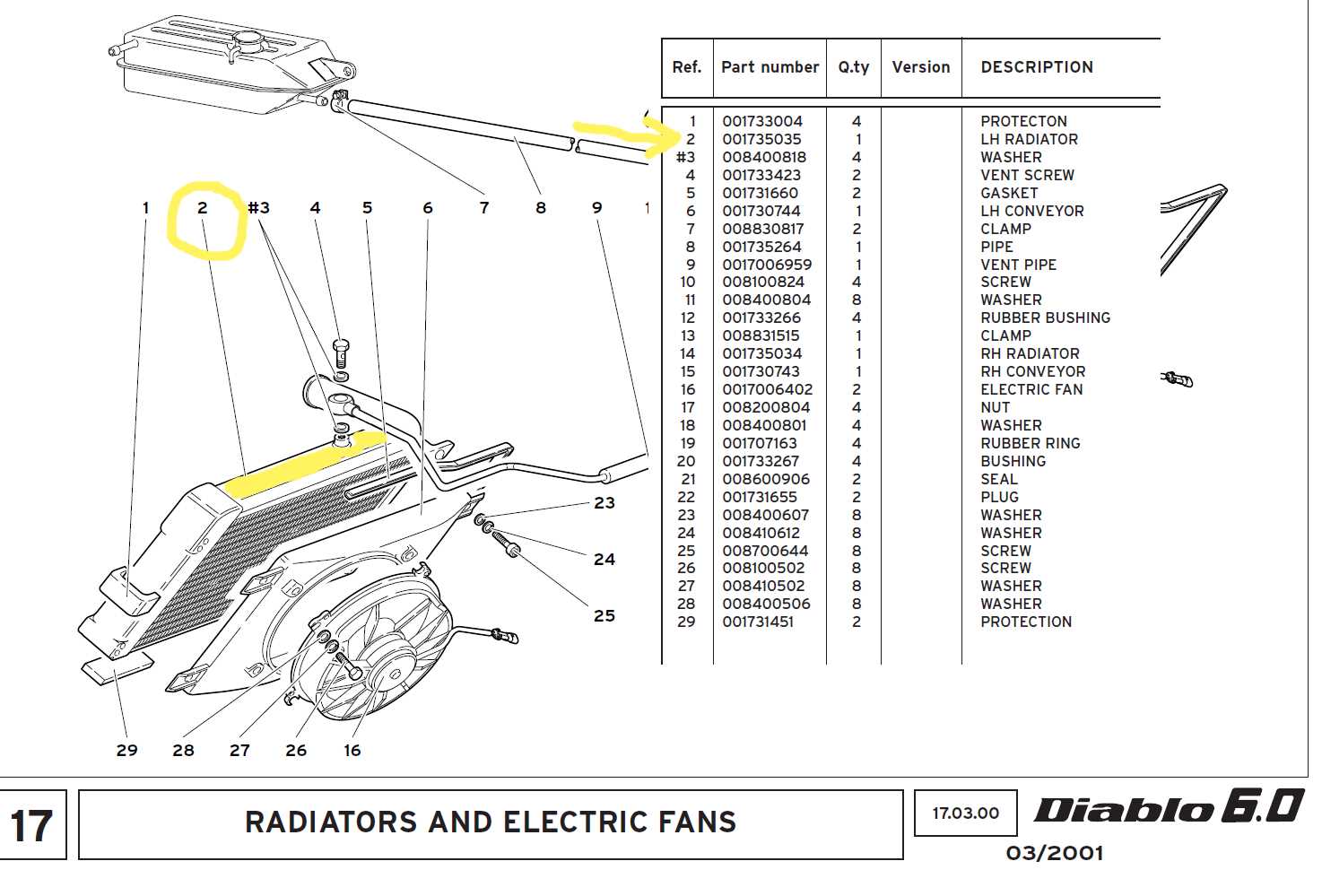

Regular inspections are critical for identifying wear and tear on essential components. Checking for any signs of damage or malfunction can help prevent larger issues from arising. It’s important to examine moving parts, belts, and hydraulic systems, ensuring they are functioning properly and making adjustments as needed to maintain peak performance.

Lubrication and Cleaning Practices

Lubricating key areas reduces friction and prevents unnecessary wear on parts. Cleaning the machine after each use ensures that debris and dirt do not accumulate, which can lead to blockages or mechanical stress. Proper lubrication and cleaning routines contribute to the overall longevity and efficiency of the equipment, helping to avoid costly repairs.