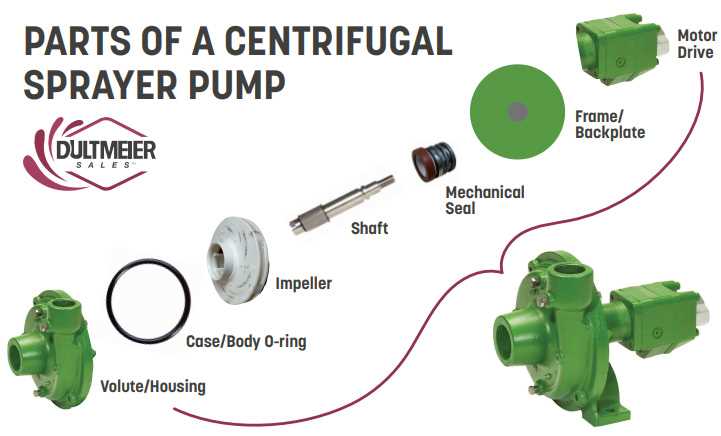

When working with mechanical systems, having a clear understanding of each component and its function is crucial for effective operation and maintenance. The interaction between different elements is key to ensuring smooth performance and identifying potential issues before they become significant problems.

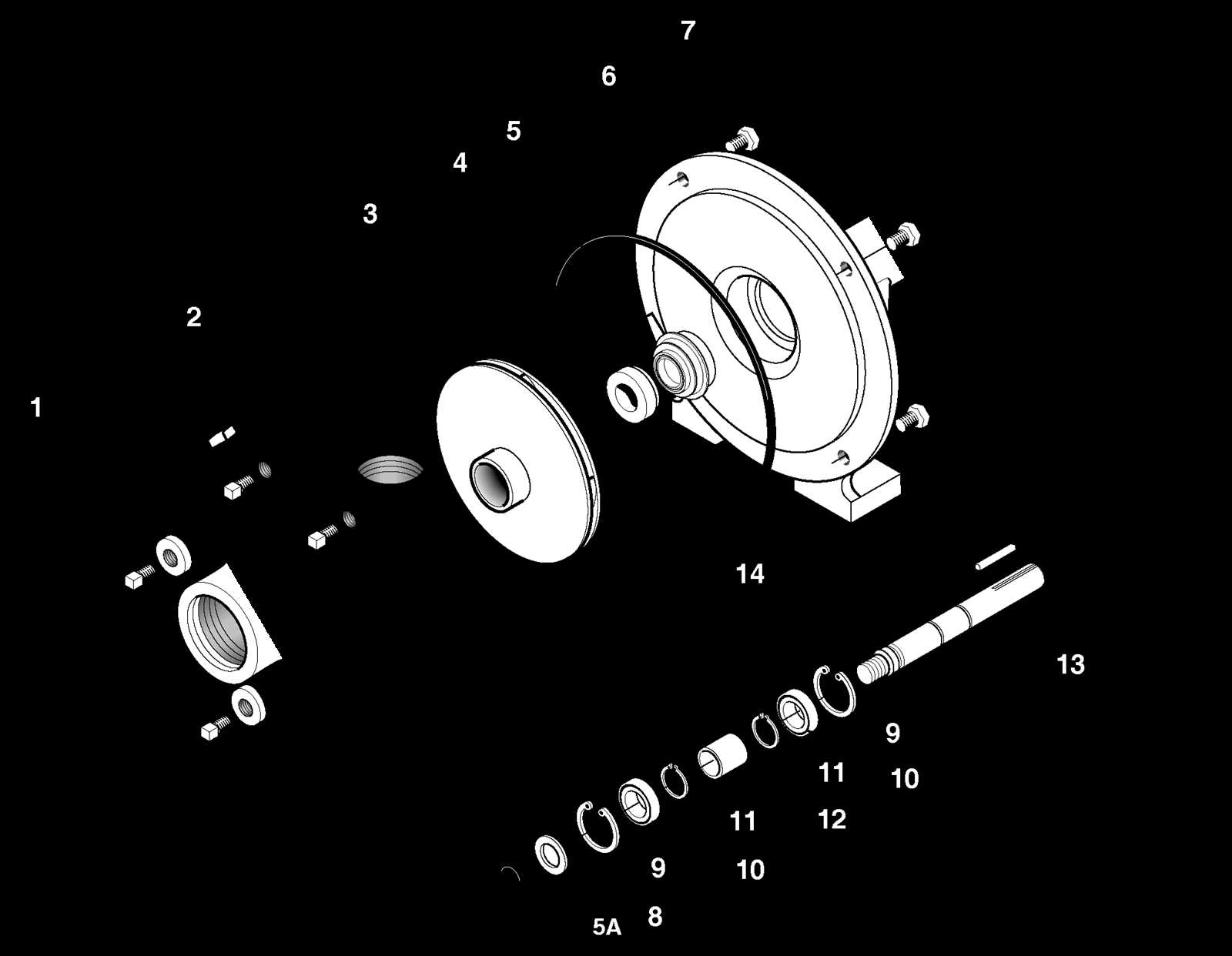

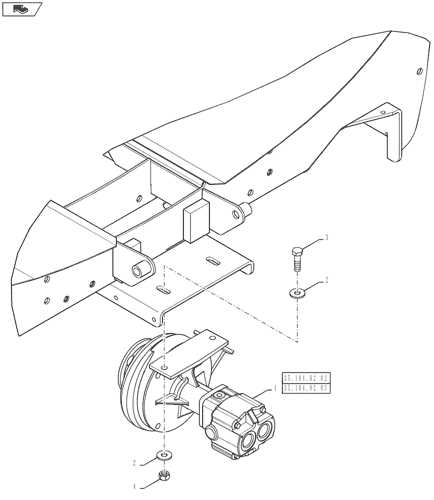

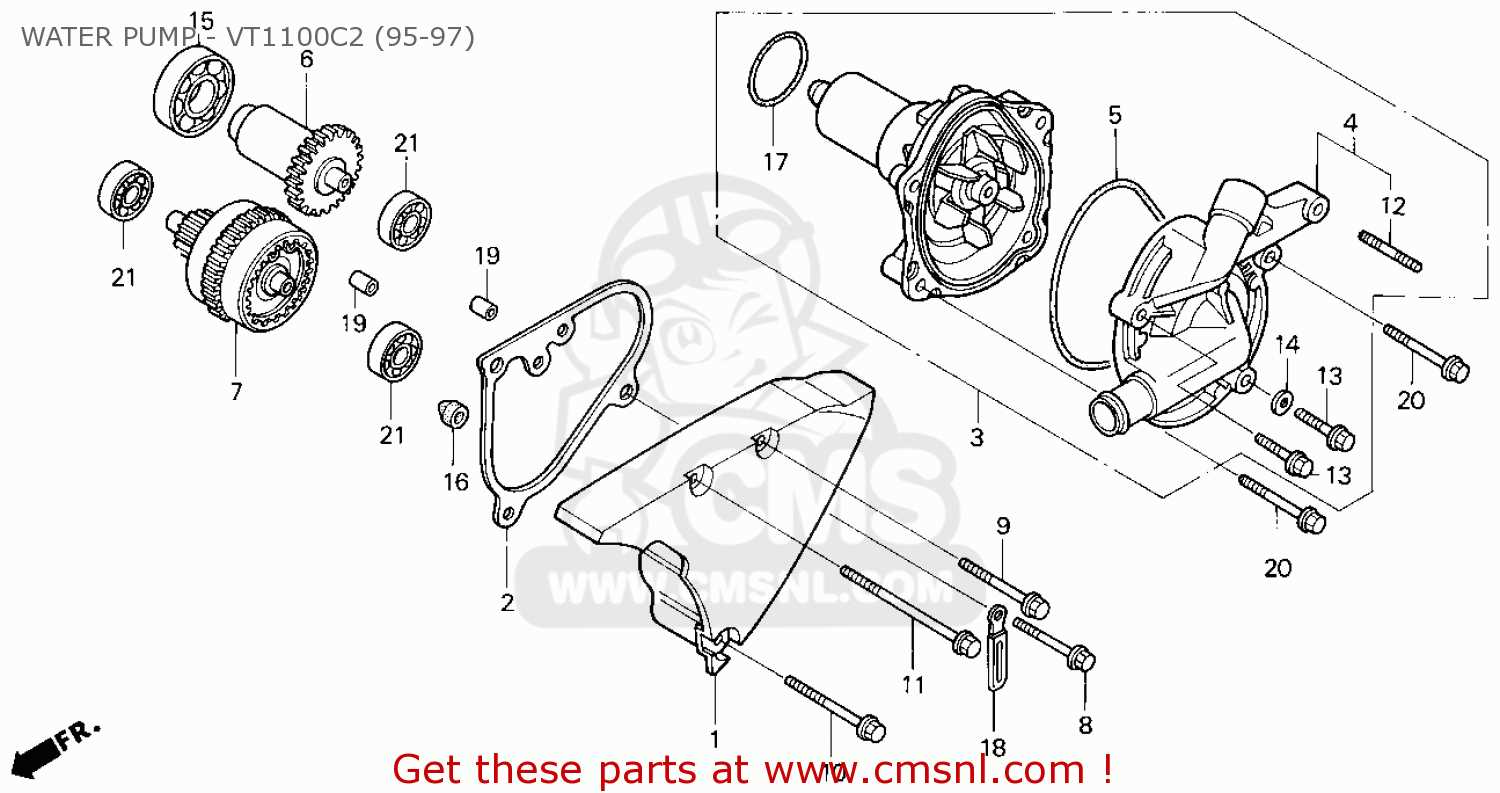

Knowing how to interpret technical illustrations that outline these components is essential for technicians and engineers alike. These visual aids provide a clear representation of how the various parts work together, making it easier to identify, troubleshoot, and replace specific elements when necessary.

Proper knowledge and maintenance of these systems can greatly extend their lifespan, reduce downtime, and improve overall efficiency. Understanding the structure and function of each element is not just beneficial for repairs but also for optimizing the system’s performance in the long run.

Understanding the System Components

To ensure optimal performance and reliability, it is crucial to have a comprehensive understanding of the various elements within a mechanical system. Each component serves a specific role, contributing to the overall efficiency of the operation. Recognizing the function of each part helps in troubleshooting and making informed decisions during maintenance or repair processes.

The system relies on an intricate network of interrelated components. Each part interacts with others to drive the desired action, whether it involves fluid movement, energy transfer, or pressure regulation. Familiarity with the structure and function of these elements allows for quicker identification of potential issues and more effective solutions.

Knowledge of the different elements involved aids in extending the lifespan of the system and maintaining high performance over time. Regular inspection and understanding the specific roles of each part are key to minimizing wear and tear, preventing breakdowns, and improving overall system reliability.

How to Read a System Schematic

Understanding technical illustrations is essential for anyone working with complex mechanical systems. These visual representations highlight the arrangement and relationship between various elements, helping technicians and engineers quickly grasp how the system operates. Knowing how to interpret these schematics can significantly streamline troubleshooting, maintenance, and repairs.

Each symbol on the illustration represents a specific component, with lines showing how they are interconnected. Familiarizing yourself with the common symbols and the flow of the system is the first step in reading these diagrams effectively. Understanding the layout will allow you to pinpoint areas of concern and assess the system’s overall performance with greater accuracy.

By carefully analyzing the schematic, you can identify potential issues, understand the role of each element, and determine which parts require attention or replacement. This knowledge is crucial for maintaining the system’s efficiency and ensuring that repairs are done correctly and promptly.

Importance of Proper Maintenance

Regular upkeep of mechanical systems is essential for ensuring their longevity, reliability, and optimal performance. Neglecting maintenance can lead to premature wear, costly repairs, and system downtime. A well-maintained system operates more efficiently, reduces the risk of unexpected failures, and supports overall productivity.

Prevents Costly Repairs

By addressing small issues early through routine inspections, potential problems can be identified before they escalate into more severe damage. This proactive approach helps avoid expensive repairs and unplanned downtime, keeping operations running smoothly and cost-effectively.

Ensures Reliable Performance

Proper care and maintenance ensure that all components function as intended, preventing disruptions in system performance. A well-maintained system is less likely to experience sudden failures, offering greater reliability and a more consistent output, which is crucial for maintaining productivity and meeting deadlines.