Understanding the various components of machinery attachments is essential for efficient operation and maintenance. Each part plays a critical role in the overall functionality, ensuring smooth performance during excavation tasks. A clear overview of these elements helps operators identify issues and maintain the equipment properly.

Maintenance knowledge is key for extending the lifespan of any mechanical tool. By familiarizing yourself with the individual pieces that work together, you can troubleshoot and make informed decisions when repairs or replacements are needed. This knowledge not only improves safety but also enhances operational efficiency.

Whether you are a seasoned operator or new to the industry, understanding the structure of these attachments is a valuable asset. With proper guidance, you can confidently tackle any maintenance challenges and ensure that your equipment remains in peak condition for years to come.

Understanding Excavator Attachment Components

Every heavy-duty tool is built from a combination of intricate pieces that work together to perform specific functions. Recognizing how each component contributes to the overall mechanism helps operators ensure the smooth operation of their equipment. Proper understanding allows for quicker identification of issues and prevents costly repairs.

Components such as the drive assembly, transmission, and other mechanical elements are essential for efficient operation. These work in unison to generate the power needed for digging, lifting, and moving materials. Knowing how each section interacts with the others can improve performance and longevity.

For anyone responsible for the upkeep of such machinery, recognizing and diagnosing problems early is vital. Familiarity with each part’s role in the overall system simplifies the maintenance process, making it easier to perform adjustments or replace worn-out parts when necessary.

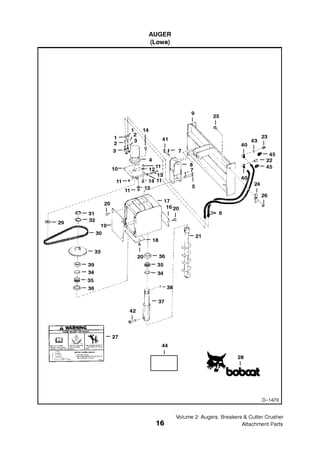

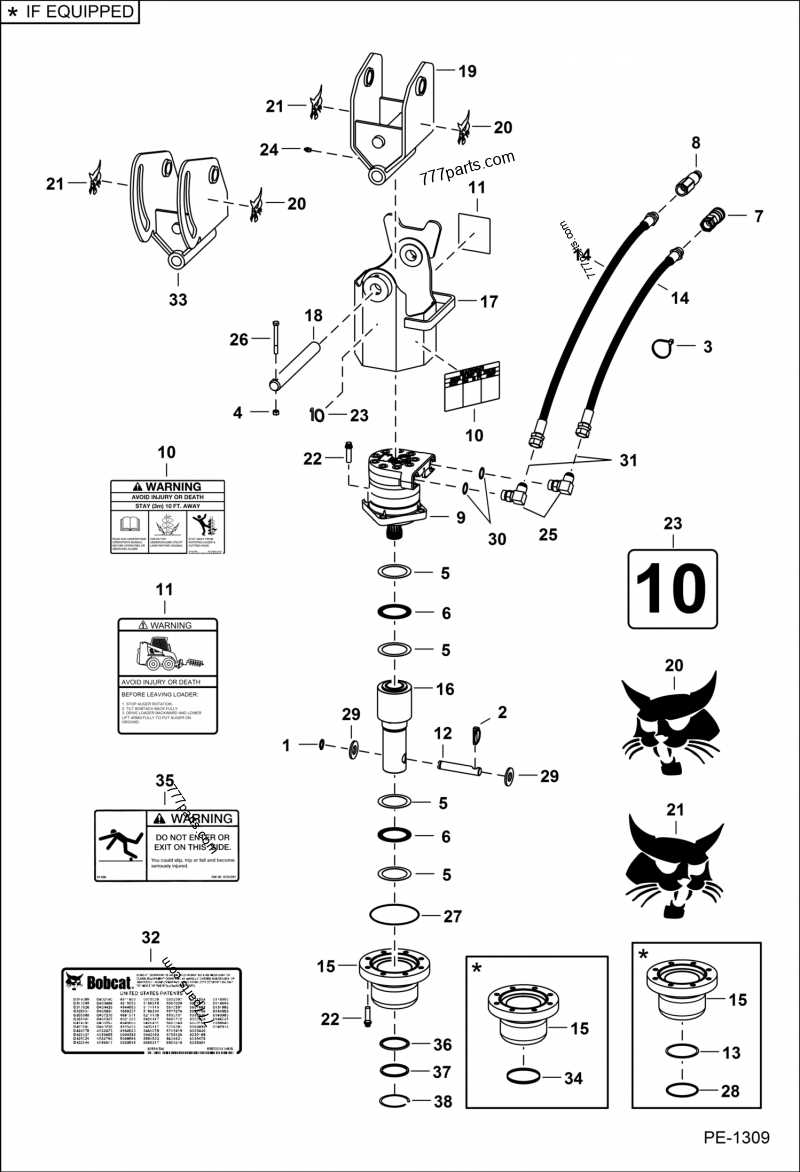

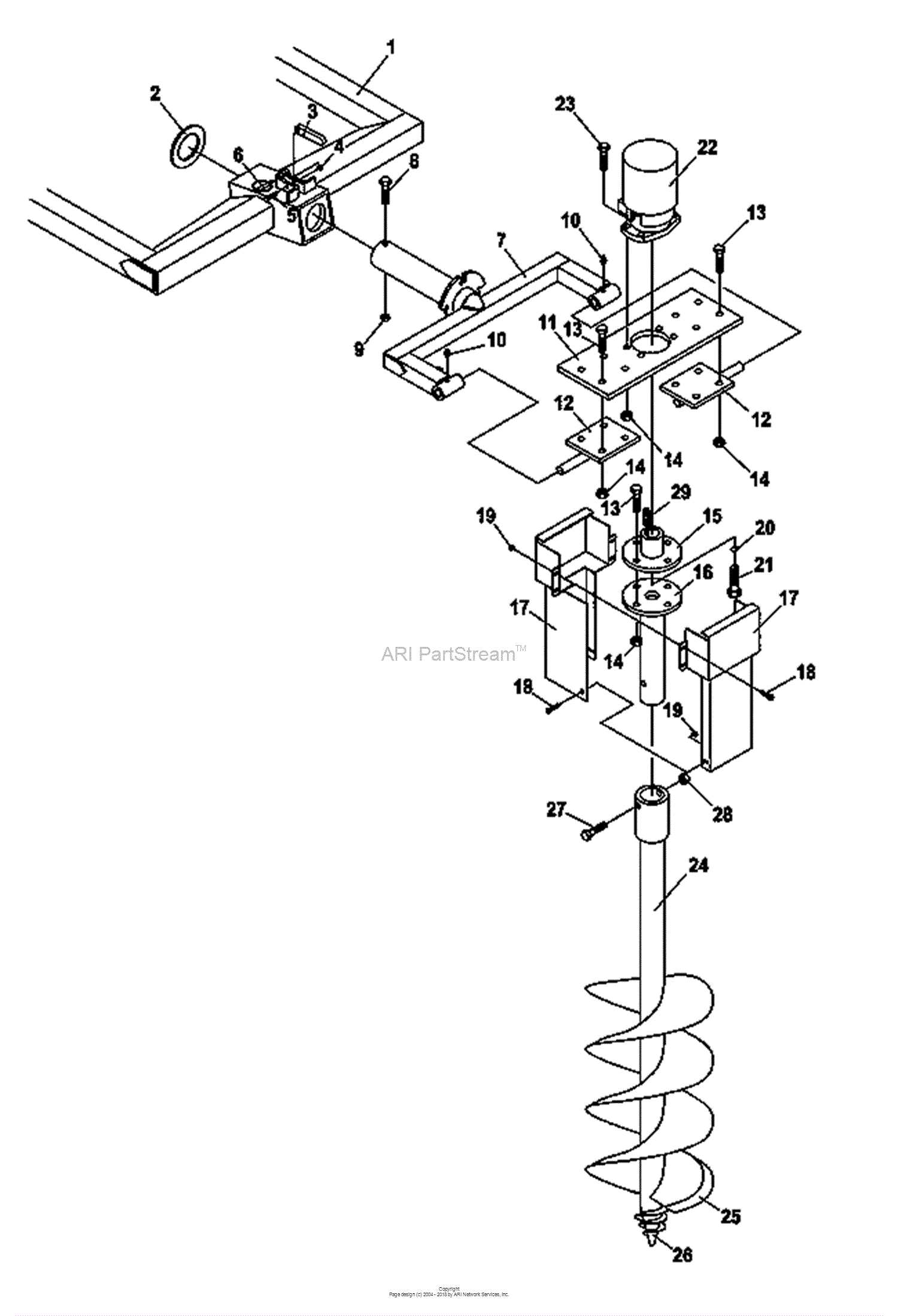

How to Identify Attachment Components on Diagram

Recognizing the individual components on a mechanical layout is essential for proper maintenance and repairs. A well-detailed illustration provides a clear view of each element’s placement and function, helping users to understand how the system operates as a whole. Identifying each section allows for precise troubleshooting and efficient repairs.

Step-by-Step Identification

The first step in understanding any layout is to familiarize yourself with the key features, such as the drive mechanism, support structure, and control elements. Each section will typically be labeled with part numbers or symbols, which correspond to specific components. Pay close attention to the connections between each element as they indicate how the parts interact within the system.

Commonly Found Components

Common components that are highlighted in diagrams include the motor, hydraulic system, and mounting frame. These are often the areas most subject to wear and tear, so knowing their exact locations can help in diagnosing problems early. With practice, you’ll become more proficient at identifying these key pieces and understanding their specific roles.

Steps for Attachment Maintenance and Repairs

Regular maintenance is crucial for ensuring the longevity and efficient operation of any mechanical tool. Proper upkeep not only prevents unexpected breakdowns but also enhances the performance of the equipment. Understanding the right steps for care and repair ensures that all components function smoothly, minimizing downtime and repair costs.

Routine Inspection and Cleaning

Begin by thoroughly inspecting the equipment for any signs of wear, damage, or loose connections. Check key elements like the motor, hydraulic lines, and structural supports. Cleaning these components helps prevent the build-up of dirt or debris, which can lead to malfunction. Lubrication of moving parts also reduces friction and extends the life of the tool.

Repairing or Replacing Damaged Components

If any part is identified as worn out or damaged, it’s important to address the issue promptly. Follow the manufacturer’s guidelines to replace faulty components, ensuring that the new parts are of the correct specifications. Always use high-quality replacement parts to maintain optimal performance and avoid future issues.