When working with complex machinery or equipment, having a clear visual representation of its internal structure is essential for successful maintenance and repairs. A detailed map of the individual elements can save time and reduce errors during troubleshooting. Knowing how to interpret these schematics is key to understanding the arrangement and function of each part within the system.

In this section, we will guide you through the important components and their relationships. By focusing on the essential elements, you’ll be able to better navigate and identify the various pieces that contribute to the overall operation. Properly interpreting these visuals ensures that you can address issues effectively and keep the system running smoothly.

Understanding the System Layout and Components

A clear and organized layout of the internal structure is crucial for effective operation and repair of any technical system. By understanding how the different elements are arranged, one can gain a better insight into the system’s overall functionality. This knowledge helps with both identifying issues and ensuring optimal performance.

To fully comprehend the arrangement, it is important to focus on how the various sections interact and contribute to the overall process. The key is to break down the layout into smaller, manageable components, which can be understood more easily. Here’s a guide to the essential components and their roles within the layout:

- Power Source: The energy provider that initiates the system’s functionality, often the first point of analysis when troubleshooting.

- Control Mechanism: This regulates the flow of operations, ensuring each part performs its task at the right time.

- Connecting Elements: These establish the necessary links between different sections, enabling the proper interaction of parts.

- Output System: The part responsible for completing the process, delivering the final result of the system’s operations.

Each of these components plays a distinct yet interconnected role. Understanding their individual functions and their positions within the layout will make maintenance and diagnostics much easier. It’s important to approach this analysis methodically, ensuring no part is overlooked.

How to Read the System Layout

Understanding technical schematics is a vital skill for anyone working with machinery or complex systems. These visual guides provide a detailed map of how components are arranged and how they interact. Properly interpreting these visuals can significantly improve troubleshooting and maintenance tasks by allowing you to quickly identify problem areas and understand the overall design.

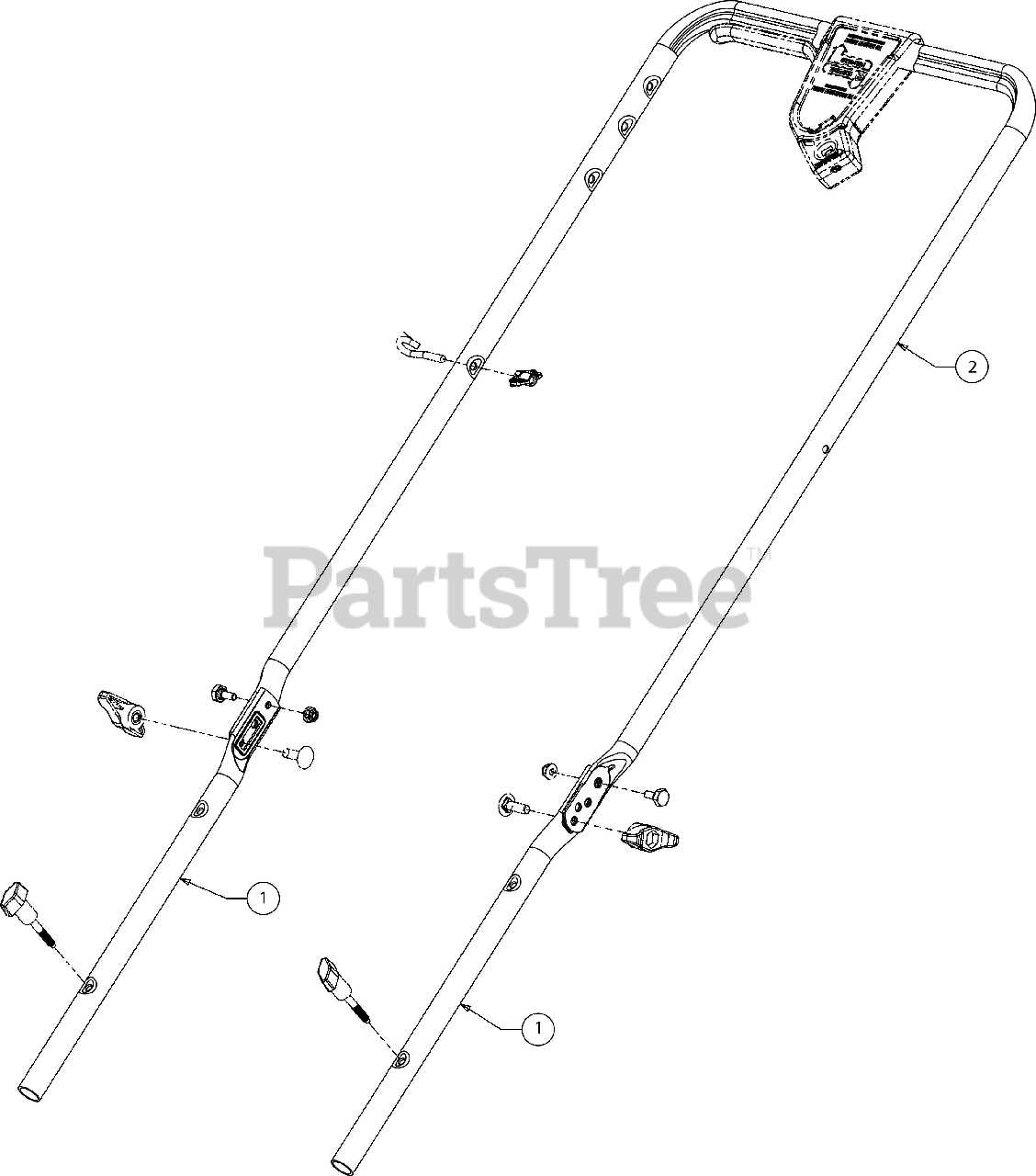

To effectively read a system layout, start by familiarizing yourself with the key symbols and notations used in the guide. These symbols represent different parts and connections, making it easy to recognize components at a glance. Next, focus on the flow of operations, from the power source to the final output. This flow will help you understand how energy or signals move through the system, indicating which components are critical to its functioning.

Additionally, pay attention to the labeling of each section. Often, diagrams will have numbers or letters corresponding to each part or area, which can be cross-referenced with a legend or parts list for clarification. This step ensures you are looking at the correct details and helps avoid confusion when analyzing specific parts.

Key Components of the System

Every technical system relies on several essential components that work together to ensure proper functionality. Understanding the role of each element is crucial for maintenance, troubleshooting, and efficient operation. By identifying these key pieces and their interconnections, you can more effectively diagnose issues and optimize performance.

Among the critical elements, the power source is the driving force, supplying the necessary energy to the entire system. Without it, no operation would be possible. The control unit follows closely, directing the flow of operations and ensuring that each component functions at the right time. Connecting components like wires and connectors form the infrastructure that enables communication between different sections, facilitating smooth interactions.

In addition to these core components, the output mechanism completes the system’s cycle, converting the internal processes into a usable result. Each of these parts is vital for the overall system’s efficiency, and understanding how they integrate will make troubleshooting and repairs much easier.