When it comes to essential water supply systems, understanding their structure is crucial for proper maintenance and efficient operation. These systems are made up of several interconnected elements, each playing a unique role in ensuring the flow and pressure of water are optimal when needed.

Identifying individual components is vital for those responsible for the upkeep of these systems. By understanding how each part functions, it becomes easier to identify issues, conduct repairs, or even replace worn-out pieces. A clear breakdown of these crucial pieces can prevent costly downtime and improve system reliability.

Familiarizing yourself with the overall design allows for better intervention during emergency situations, ensuring quick restoration of water flow. By recognizing the features of each segment, users can maintain and repair the system with greater precision and confidence.

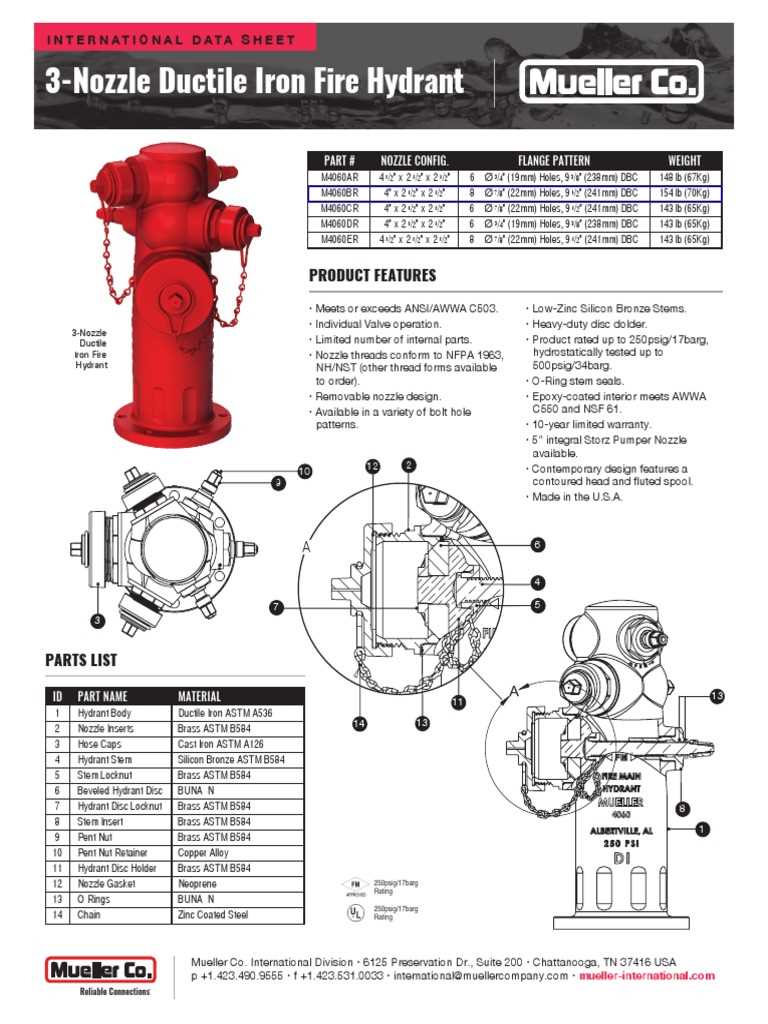

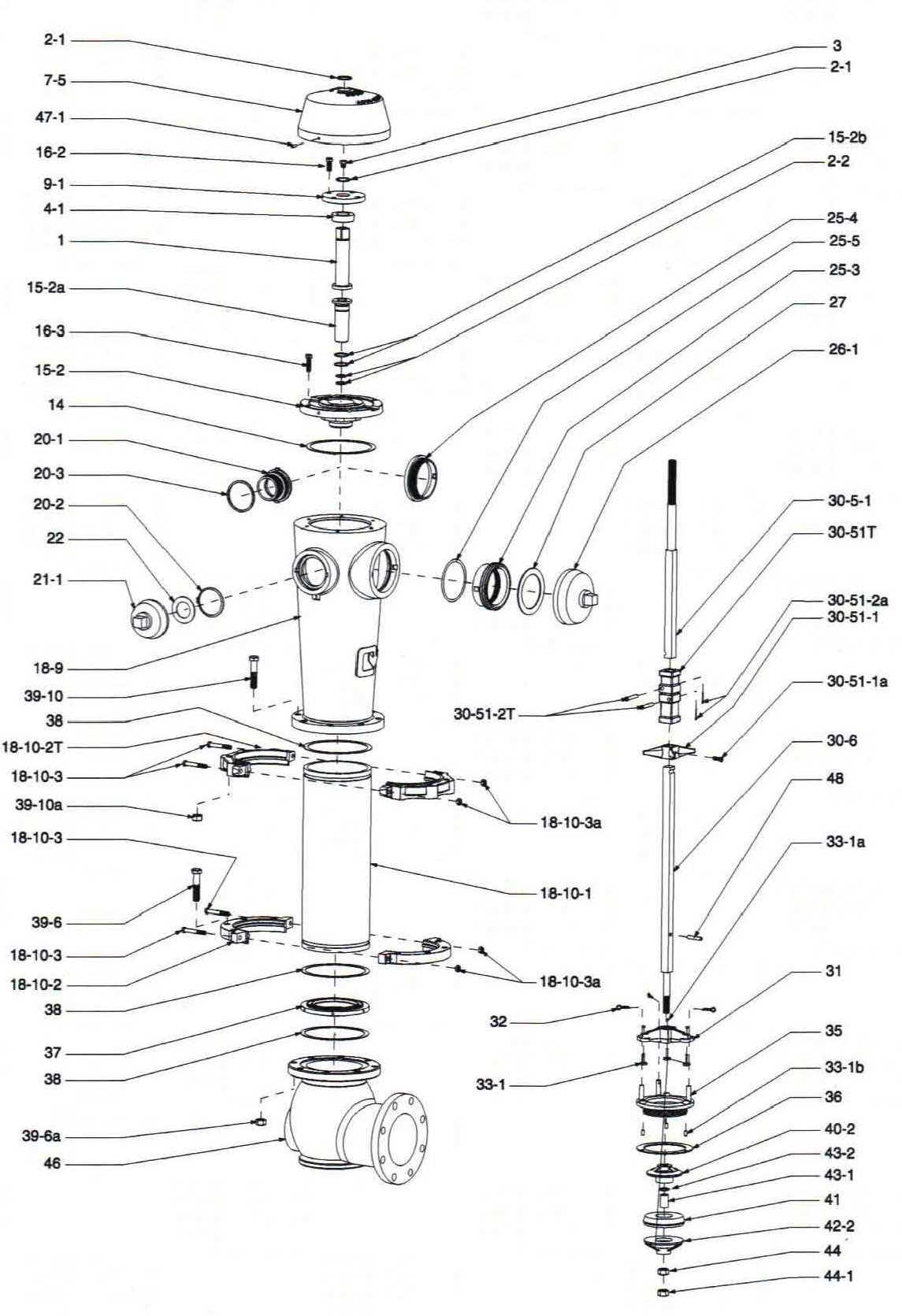

Understanding Hydration System Components

Every water distribution system is made up of several essential elements that work together to ensure proper functionality. These components are specifically designed to manage and direct the flow of water, each serving a unique purpose in the overall structure. A comprehensive understanding of these parts can help ensure the system remains reliable and effective when needed most.

Among the key elements are those that control water flow, maintain pressure, and allow for safe and easy access during emergency situations. Each component contributes to the efficiency and safety of the entire setup, making it crucial to understand their design and operation. Regular checks and maintenance of these parts can prevent potential issues and improve the longevity of the system.

Key Parts of Hydration System Assembly

A water distribution system consists of several vital elements, each performing specific functions that contribute to its efficiency. These components work in tandem to ensure proper water flow, accessibility, and pressure control during operations. Understanding the main segments of the assembly is essential for anyone involved in its installation, maintenance, or troubleshooting.

The most important pieces include those responsible for directing the water, securing the system, and ensuring quick operation during emergency use. Regular examination and upkeep of these components can help prevent malfunctions and extend the system’s lifespan. Identifying these key parts and their roles makes it easier to perform necessary maintenance tasks and address any issues promptly.

How to Maintain Water Distribution System Components

Proper maintenance of the components within a water distribution system is essential for ensuring its longevity and efficient operation. Regular checks and servicing of these elements can prevent issues, reduce downtime, and ensure that everything functions as expected when needed. A proactive approach to maintenance will also help avoid costly repairs in the future.

Key aspects of maintenance include cleaning, lubricating moving parts, and inspecting seals and valves for wear. It’s also crucial to test the system periodically to confirm that all components are in good working order. Identifying any signs of damage early on allows for timely repairs and ensures that the system remains reliable and ready for use at all times.