Maintaining and repairing complex systems can be a challenging task without the right knowledge. A clear understanding of each individual part and its role in the overall operation is essential for effective maintenance and troubleshooting. Proper guidance ensures that you can keep your machinery running smoothly and efficiently, minimizing downtime and avoiding costly repairs.

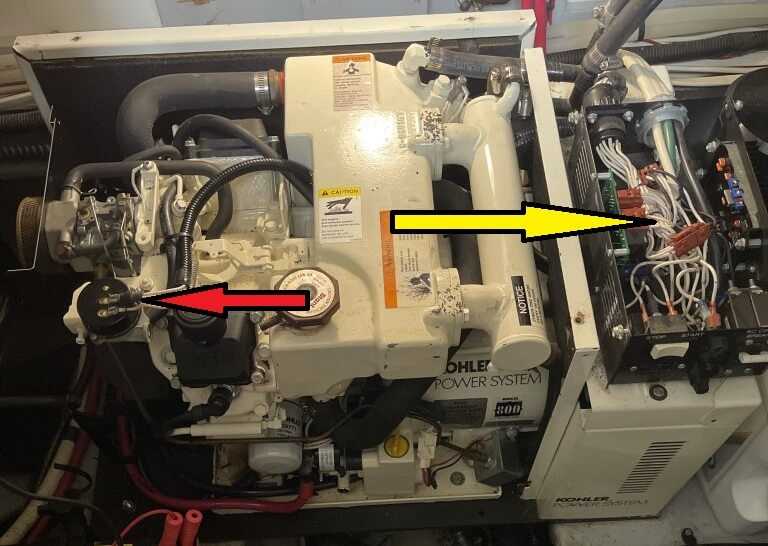

In this section, we will explore the key components that make up a typical power system and provide a visual representation to help you navigate through each part. Knowing how these elements interact allows you to identify potential issues early and make informed decisions regarding repairs or replacements.

By familiarizing yourself with the structure and functions of each element, you can gain confidence in handling regular maintenance and addressing unexpected challenges. This knowledge will be crucial in ensuring the longevity and performance of your equipment.

Understanding Kohler 5e Generator Components

Every system designed for power production consists of multiple interconnected elements that work together to ensure smooth operation. Each component has a specific function that contributes to the overall performance and reliability. Understanding these elements can help you identify when a malfunction occurs and guide you in troubleshooting effectively.

Key Elements of the Power System

The structure of the system includes various mechanisms, each responsible for a distinct task, such as fuel delivery, energy conversion, and electrical regulation. The interaction between these components ensures the system operates at peak efficiency. From fuel pumps to voltage regulators, each part plays a crucial role in ensuring the unit functions as intended.

Impact of Component Failure

If one part fails, the entire system can be affected. Common issues, such as improper fuel flow or a malfunctioning alternator, can cause the system to underperform or fail completely. Regular checks and maintenance of these elements can prevent major breakdowns and extend the lifespan of your equipment.

How to Read the Parts Diagram

Understanding how to interpret technical illustrations is an essential skill for anyone working with complex machinery. These visual guides provide a detailed representation of the system, highlighting each component and its relationship to others. By learning how to read these illustrations, you can better understand the layout, identify potential issues, and perform maintenance or repairs more efficiently.

Interpreting Key Symbols and Labels

Technical drawings often use specific symbols and labels to represent components and their functions. Recognizing these symbols is crucial for accurate interpretation. Here are some common elements you’ll find:

- Numbers: Often used to identify individual parts or locations.

- Lines: Indicate connections between different components.

- Shapes: Represent specific types of equipment, such as pumps or electrical units.

Understanding Component Placement and Relationships

Components are usually arranged in a way that reflects how they interact within the system. Follow the flow from one part to another, keeping track of the connections and sequences. This will help you understand how each element contributes to the overall function. Pay attention to:

- The direction of flow (fuel, electricity, etc.) through the system.

- The proximity of related components, such as those involved in energy conversion or safety monitoring.

Common Issues and Replacement Parts

Every mechanical system is subject to wear and tear over time, leading to various issues that can hinder its performance. Identifying these common problems early and replacing damaged elements can prevent larger failures and extend the life of the equipment. Understanding the most frequent malfunctions and their corresponding replacements will help you keep the system in top condition.

Frequent Problems Encountered

Some of the most common issues include:

- Fuel Flow Disruptions: Clogged filters or faulty pumps can cause insufficient fuel delivery, leading to poor performance.

- Electrical Failures: Damaged wires or malfunctioning regulators can result in power interruptions or electrical imbalances.

- Overheating: Insufficient cooling or blocked vents can cause components to overheat, leading to potential damage.

Essential Replacements

To address these problems, certain components may need to be replaced. Here are some common replacements to consider:

- Fuel Filters: Regular replacement helps maintain proper fuel flow and prevents engine performance issues.

- Wiring and Fuses: Replacing worn-out or corroded wires ensures proper electrical function and avoids short circuits.

- Cooling Fans and Vents: Replacing damaged cooling components prevents overheating and extends the lifespan of the system.