When maintaining outdoor power equipment, understanding its inner workings is essential for keeping it in optimal condition. Identifying the correct components and knowing their functions can save time, money, and prevent unnecessary repairs. This guide will provide clear information on how to locate and replace the most important elements, ensuring smooth operation of your equipment.

Having access to a visual reference is crucial for quick and efficient repairs. By learning how to interpret these resources, you can easily locate the part that needs attention, whether it’s a replacement or routine maintenance task. Clear illustrations and detailed descriptions offer step-by-step guidance, making the process more accessible for all users.

With this knowledge, you’ll be better prepared to handle common issues, troubleshoot problems, and make necessary adjustments to improve performance. Taking a proactive approach to care and maintenance ensures longevity and reliability for your outdoor tools, allowing them to perform their best when needed most.

Poulan Pro 25cc Pole Saw Overview

This tool is designed to help with trimming and cutting branches at height without the need for a ladder or scaffold. Built for both convenience and efficiency, it is a popular choice among homeowners and professionals alike. With a lightweight frame and easy maneuverability, it ensures that users can perform necessary tasks with ease.

The equipment is equipped with an engine that provides sufficient power to handle a variety of cutting jobs, from light trimming to heavier-duty work. It is also designed with durability in mind, ensuring reliable operation through extended use. The construction of the tool focuses on minimizing fatigue, with ergonomic features that enhance comfort during longer working sessions.

Key features include:

- Lightweight and easy to handle, reducing strain on the user

- Powerful engine capable of tackling a range of cutting tasks

- Durable materials for long-lasting use

- Ergonomic design for increased comfort and control

- Efficient and quick maintenance for optimal performance

Whether you’re managing tree branches, shrubs, or other outdoor projects, this tool provides the reliability and performance needed to get the job done efficiently. It offers a practical solution for both professional landscapers and DIY enthusiasts, helping them achieve precise cuts with minimal effort.

Understanding the Parts and Their Functions

To keep your outdoor power tool in top condition, it is essential to understand the various components that make it function. Each element plays a specific role in ensuring the tool operates smoothly and efficiently. From the engine to the cutting mechanism, knowing how these parts work together can help you perform maintenance tasks more effectively and troubleshoot any issues that arise.

The engine is the heart of the machine, providing the necessary power to drive all the functions. It converts fuel into mechanical energy, which powers the system. Next, the drive shaft transfers this energy to the working parts, including the cutting assembly, ensuring smooth and consistent performance.

The cutting head is responsible for the tool’s main function, whether it’s slicing through branches or trimming other foliage. It houses the blades or cutting chains, which are powered by the engine’s motion and designed for precision. Meanwhile, the fuel tank supplies the energy needed for the engine, and the air filter ensures that only clean air reaches the engine, keeping it running efficiently.

Additional components such as the handle and trigger give the user control over the device, making it easier to guide and operate. Each of these elements is crucial for the performance and safety of the machine. Proper care and timely replacement of any faulty parts can greatly extend the life of your equipment and improve its functionality.

How to Use the Parts Diagram Effectively

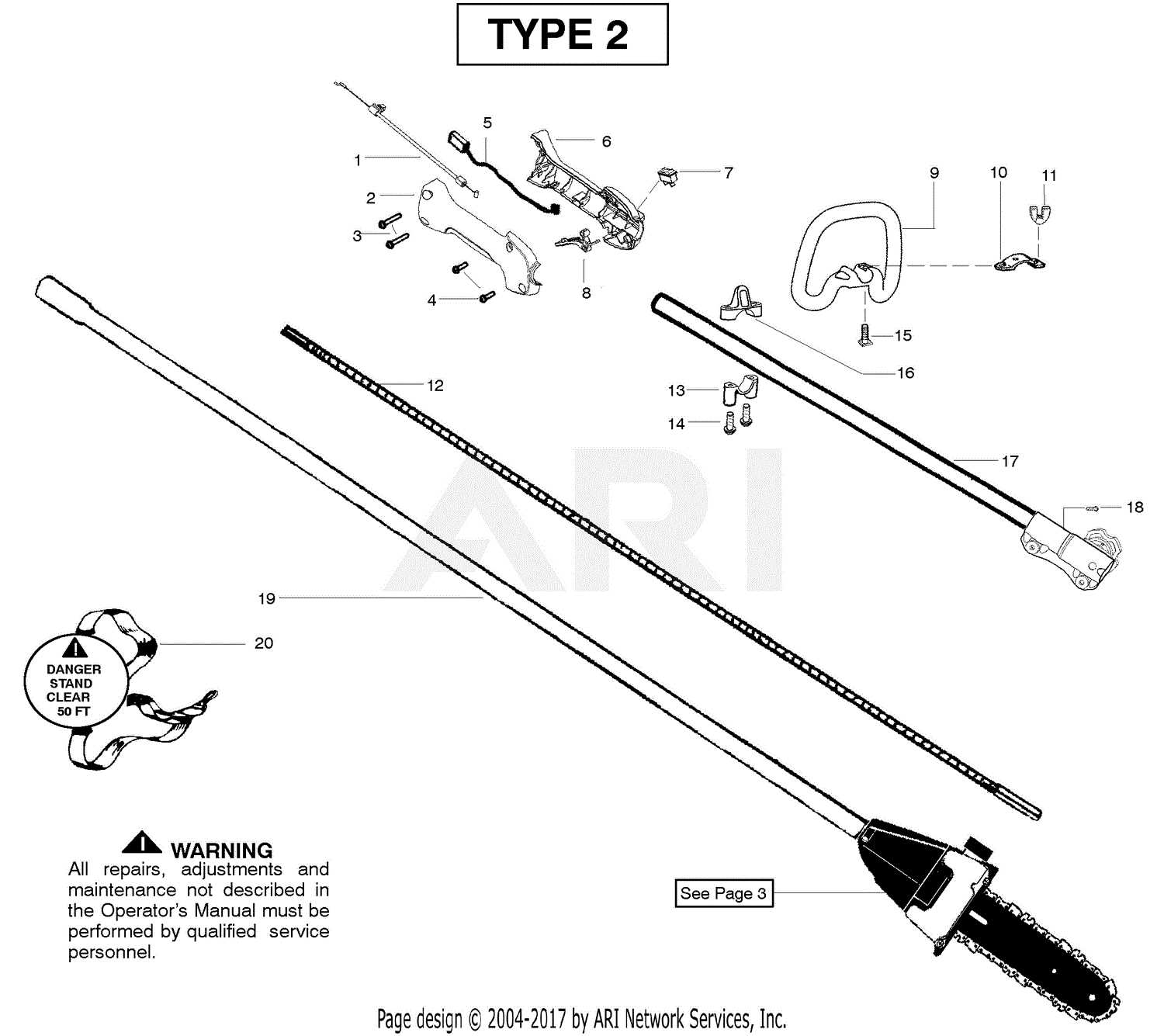

When maintaining or repairing your outdoor equipment, visual references are invaluable. These illustrations provide a clear overview of the different components, making it easier to identify and locate specific parts. By learning how to read and interpret these resources, you can improve your ability to perform repairs, replacements, and maintenance tasks with confidence and precision.

Start by Familiarizing Yourself with the Layout

Before diving into any repair work, it’s important to take some time to familiarize yourself with the layout of the reference guide. Typically, these images will show an exploded view of the tool, with labels indicating the names and locations of each component. Understanding how the parts are arranged will help you visualize the overall structure and pinpoint the correct part when it’s time for a replacement.

Follow the Numbers and Labels Carefully

Many diagrams use numbering systems or color coding to match parts with their corresponding names. Pay close attention to these labels, as they can guide you through the process of disassembly and reassembly. If you’re looking for a specific component, check the numbers or the reference key to quickly locate it in the diagram. This approach helps avoid confusion and ensures that you’re working with the correct part every time.

By using these visual aids effectively, you’ll be able to streamline the repair process, reduce errors, and keep your tool in excellent working condition for longer periods of time.

Step-by-Step Guide for Maintenance

Regular upkeep is essential for ensuring that your outdoor equipment operates efficiently and lasts longer. By following a structured maintenance routine, you can prevent common issues and keep your tool performing at its best. This guide will take you through the necessary steps for proper care, from basic cleaning to more advanced procedures, ensuring optimal functionality over time.

1. Clean the Equipment Thoroughly

The first step in any maintenance routine is to clean the tool after each use. Remove any debris, dirt, or grass clippings that may have accumulated on the frame or the cutting mechanism. Use a soft brush or compressed air to dislodge particles from hard-to-reach areas. Keeping the equipment clean helps prevent wear and tear, especially on the moving parts.

2. Check and Replace the Fuel

Make sure that the fuel is fresh and hasn’t gone stale, as old fuel can damage the engine. Empty the tank after extended periods of inactivity, and refill it with the appropriate mixture if needed. Additionally, inspect the fuel lines for any signs of cracks or leaks, and replace them if necessary to ensure smooth operation.

By following these steps, you can avoid common performance issues and keep your tool running smoothly for years to come. Regular maintenance also ensures safety during use and minimizes the likelihood of costly repairs.

Troubleshooting Common Issues with Parts

Even with proper maintenance, issues can occasionally arise with outdoor tools. Identifying and resolving these problems quickly can help extend the life of your equipment and keep it working efficiently. Common issues often stem from wear and tear on various components, and recognizing these signs early can save you from more costly repairs in the future.

One of the most common problems is engine failure, which can result from fuel contamination, a clogged air filter, or a faulty spark plug. If the engine is not starting, check the fuel for freshness and replace the spark plug if necessary. Additionally, cleaning or replacing the air filter can restore airflow to the engine, ensuring better performance.

Another frequent issue is reduced cutting efficiency, which can be caused by dull or damaged blades. If your tool struggles to make clean cuts, inspect the cutting mechanism for any signs of wear. Sharpening or replacing the blades can significantly improve performance. Similarly, ensure that the drive system is free from debris and is properly lubricated to prevent friction and wear.

Lastly, handle and trigger issues can also cause difficulty in operating the equipment. If you notice any stiffness or lack of responsiveness in the controls, check for blockages or misalignments. Regularly cleaning and inspecting these components will prevent operational difficulties and ensure a smooth user experience.