Engine maintenance and repair often require a deep understanding of the intricate systems within the machinery. One crucial aspect of this is the arrangement and functionality of various components that ensure smooth operation. Having a clear visual and technical understanding of these systems is essential for diagnosing issues and performing precise repairs.

The key to effective troubleshooting lies in knowing how the individual elements work together to deliver optimal performance. By studying their relationships and learning to interpret the configurations, professionals can pinpoint malfunctions and reduce downtime. This knowledge becomes even more powerful when accompanied by a detailed representation of each component’s role.

Exploring the internal structure of these systems equips technicians with the expertise to not only identify potential failures but also enhance the efficiency of their maintenance efforts. With the right tools and a clear layout, even the most complex machinery can be understood and serviced with confidence.

Understanding Cummins PT Fuel Pump

In any engine system, the proper functioning of key components is essential to ensure reliable performance. These systems rely on precise mechanical operations that allow energy to be efficiently transferred, controlled, and regulated. Understanding the various elements involved helps in identifying their specific roles and maintaining optimal conditions for long-term operation.

The unit in question features intricate design and complex mechanics, with each part contributing to the overall process. With a well-structured approach to its assembly, the system guarantees that energy is efficiently distributed throughout the engine. Recognizing how each segment interacts is fundamental in troubleshooting issues and improving operational efficiency.

Familiarity with the internal workings of these systems enhances maintenance procedures. By gaining insights into the configuration and purpose of each component, technicians can perform repairs more effectively and detect potential issues before they cause significant disruption. Proper knowledge empowers users to maintain peak performance and longevity.

Key Components of the Fuel Pump

Every complex mechanism relies on a series of interconnected elements, each fulfilling a distinct function to maintain smooth and efficient operation. Within a system like this, understanding the primary components is essential to both performance and maintenance. Each part works in harmony to deliver the desired output while ensuring reliability and longevity.

The Control Mechanism

At the heart of the system lies the control unit, which regulates the movement and flow of the essential elements. This component ensures that energy is distributed at the correct pressure and volume to other parts, guaranteeing consistent performance. Without this core function, the system would lack stability and efficiency.

The Energy Distribution System

The distribution system is responsible for guiding the energy throughout the various channels to the appropriate segments. By maintaining a steady and regulated flow, it ensures the correct delivery of power to all connected components. Any irregularity or failure in this system can lead to decreased functionality or malfunction of the entire unit.

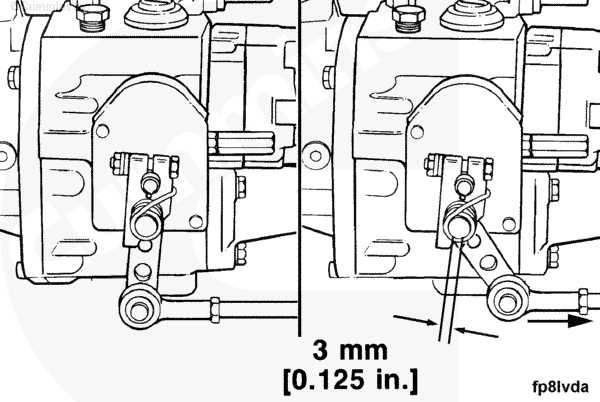

How to Read the Parts Diagram

Understanding how to interpret a technical layout is crucial when working with complex systems. These representations serve as visual guides, allowing users to locate and identify individual elements within the structure. By reading these diagrams accurately, it becomes easier to pinpoint connections, troubleshoot issues, and perform necessary maintenance tasks.

The key to success lies in recognizing symbols, labels, and the overall arrangement. Each component is represented by specific notations that describe its function and position within the system. By following the lines and relationships between the parts, one can easily gain insight into the full setup and the interactions between various sections.

When using a layout for repairs or diagnostics, always pay attention to the scaling and proportions of the components. This ensures that the representation reflects real-world measurements and dimensions, allowing for precise understanding and action. Mastering this skill not only improves efficiency but also boosts confidence in handling the system effectively.