When working with a mechanical tool, it’s essential to know the function and location of each individual piece. A clear understanding of how the components fit together can make maintenance, repairs, and troubleshooting much easier. Whether you’re replacing worn-out pieces or performing routine upkeep, knowing what each part does can save time and effort.

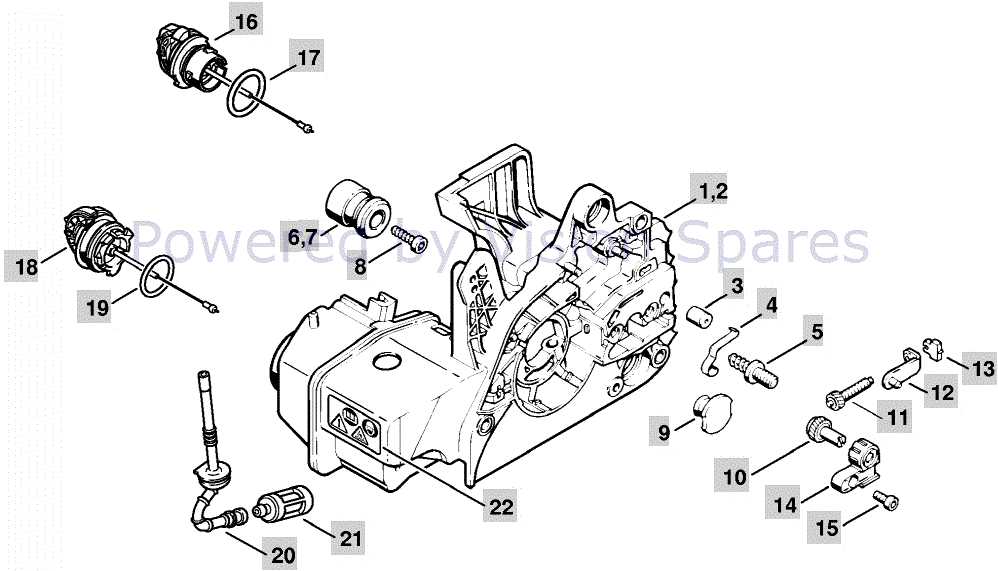

Visual aids can be incredibly helpful in identifying specific components and understanding their relationship within the overall assembly. These guides provide detailed views, allowing users to pinpoint the exact area of concern without guessing or relying on memory. Such tools enhance accuracy and precision when working on your equipment.

In this article, we’ll break down the key elements that make up the saw, offering insights into their functions and how to approach maintenance with confidence. By the end, you’ll be able to identify each part, understand its purpose, and know how to repair or replace it as needed.

Understanding the MS 250 Components

Every mechanical tool is made up of multiple interconnected elements, each serving a specific function that contributes to the overall performance. By familiarizing yourself with these individual pieces, you can ensure that your equipment remains in top condition and is ready for any task. Whether for maintenance or troubleshooting, knowing how each component works is crucial.

The key to effective maintenance lies in identifying which elements need attention or replacement. By understanding their roles and how they interact, you can quickly diagnose issues and prevent further damage. The assembly includes both basic and specialized components, each with a distinct purpose, from the motor housing to the cutting mechanism.

Recognizing these pieces and their functions can significantly improve your ability to handle repairs. Each part plays a role in making the tool efficient and reliable, and knowing them inside and out will help you make informed decisions when dealing with breakdowns or routine care.

How to Identify Saw Components

Recognizing the various elements of your tool is the first step in ensuring its proper operation. Each individual piece has a distinct function and is essential to the overall performance of the equipment. Knowing where to find each component and how it fits into the larger assembly is crucial for both maintenance and repairs.

To begin identifying these components, start by studying the tool’s external layout. Key parts like the handle, engine housing, and cutting mechanism are easy to locate. However, more intricate elements, such as internal gears or tensioning systems, may require closer inspection or a guide to fully understand their placement and function.

Using a visual guide or reference can be helpful in pointing out the exact location and role of each piece. By examining these visuals, you’ll gain a clearer picture of how everything works together. This knowledge will empower you to make informed decisions when performing repairs or adjustments to keep your equipment running smoothly.

Repair Tips Using the Parts Diagram

When it comes to fixing mechanical tools, having a clear understanding of how the different pieces fit together can make repairs much easier. Visual references that highlight the specific components within your equipment are invaluable when diagnosing and addressing issues. These guides allow you to quickly locate problematic areas and avoid unnecessary disassembly.

One of the first steps in repairing any tool is to carefully examine the broken or worn-out element. With a clear visual guide, you can match the damaged section to its corresponding component, ensuring that you replace or fix the right part. It’s important to note how each piece interacts with others, as improper reassembly can lead to further complications.

During repairs, always refer back to the guide to confirm the exact placement of each piece. This will not only help prevent mistakes but also speed up the repair process. By keeping a visual reference close at hand, you can ensure that every part is properly aligned, reducing the risk of errors and extending the life of your equipment.