When preparing for a journey with your vehicle and its attached load, it is crucial to have a clear understanding of how different elements work together to ensure a smooth and safe experience. Each component plays a specific role in the overall functioning, and recognizing them can help in proper maintenance and repairs.

The system consists of various segments, each designed to withstand specific stresses and conditions. From securing the load to maintaining balance during transport, every detail contributes to the safety and durability of the system. Proper identification and knowledge of these sections can prevent issues on the road.

Familiarity with the various components and their functions helps in diagnosing potential problems before they escalate. Whether it’s a minor adjustment or a major fix, recognizing what needs attention is a key part of maintaining the equipment’s effectiveness and longevity.

Essential Components of a Towing System

For effective hauling, it is important to understand the key elements that contribute to the overall functionality of the load-bearing setup. These crucial sections ensure stability, safety, and proper handling while transporting. Each part has a distinct purpose, designed to make the process more efficient and secure.

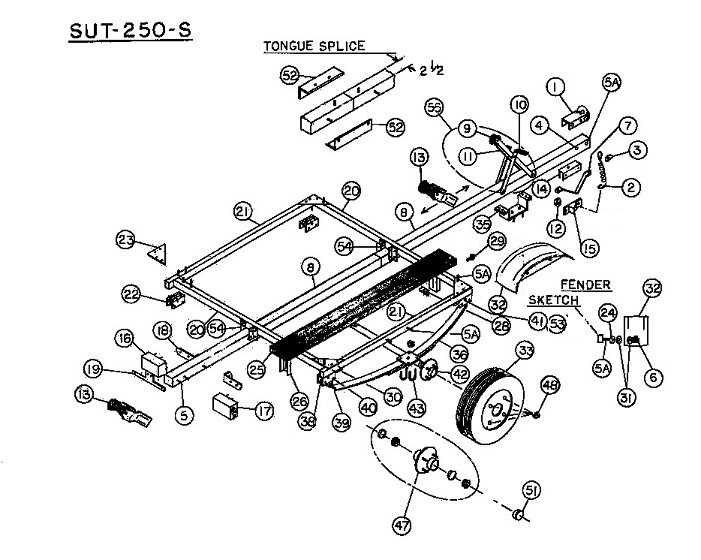

Structure and Frame

The foundation of any system relies on its frame, which provides the necessary strength to support the entire structure. Made from durable materials, the frame needs to withstand various environmental and physical stresses, offering a solid base for other components. It also needs to be resistant to corrosion and wear, ensuring long-term durability.

Load Securing Mechanisms

Effective securing mechanisms are vital for ensuring the safety of the load during transit. From adjustable supports to locking systems, these parts keep the load stable and prevent unnecessary movement. Proper use of these elements significantly reduces the risk of damage or accidents on the road.

How to Identify Towing System Components Quickly

Knowing how to recognize the essential elements of a load-bearing setup is key for effective maintenance and troubleshooting. Quick identification of individual sections can save time and help address issues before they become more serious problems. Familiarizing yourself with the common characteristics of each piece ensures a more efficient inspection process.

Visual Clues for Key Components

Each segment of the system often has distinct visual features that can be used for identification. For example, frames are typically larger, heavier structures, while securing mechanisms often have adjustable brackets or hooks. By observing these unique traits, you can rapidly pinpoint the function and type of each part.

Function and Location

Understanding the primary function of each piece and where it’s located within the structure can further expedite identification. For instance, the wheel assemblies are usually near the bottom, while stabilizing components tend to be found near the sides. Knowing the role each element plays in the system’s overall performance will help you quickly identify potential issues or areas requiring attention.

Common Issues with Towing System Components

While transporting heavy loads, certain sections of the structure are more prone to wear and damage. Recognizing these issues early on can prevent further complications and improve overall safety. Identifying and addressing the most common problems can extend the life of the system and ensure smoother operations.

Corrosion and Wear

Corrosion is one of the most common problems faced by load-bearing setups, especially in environments with high humidity or exposure to water. Over time, rust can weaken metal components, leading to structural failure. Regular cleaning and coating with protective materials can significantly reduce the effects of corrosion and prolong the life of these sections.

Loose or Damaged Securing Mechanisms

Another frequent issue involves securing mechanisms, which may become loose or damaged due to frequent use or poor maintenance. Broken locks or misaligned brackets can cause instability, risking the safety of the load during transit. Checking and adjusting these components regularly ensures that they remain effective and secure.