Proper maintenance of pool systems requires familiarity with the internal components that control water flow and filtration. Knowing how these parts function and interact is essential for ensuring optimal performance and longevity of the equipment.

Identifying each element within the system is crucial for accurate troubleshooting and repair. By understanding their layout and roles, users can easily detect potential issues and replace faulty parts when necessary.

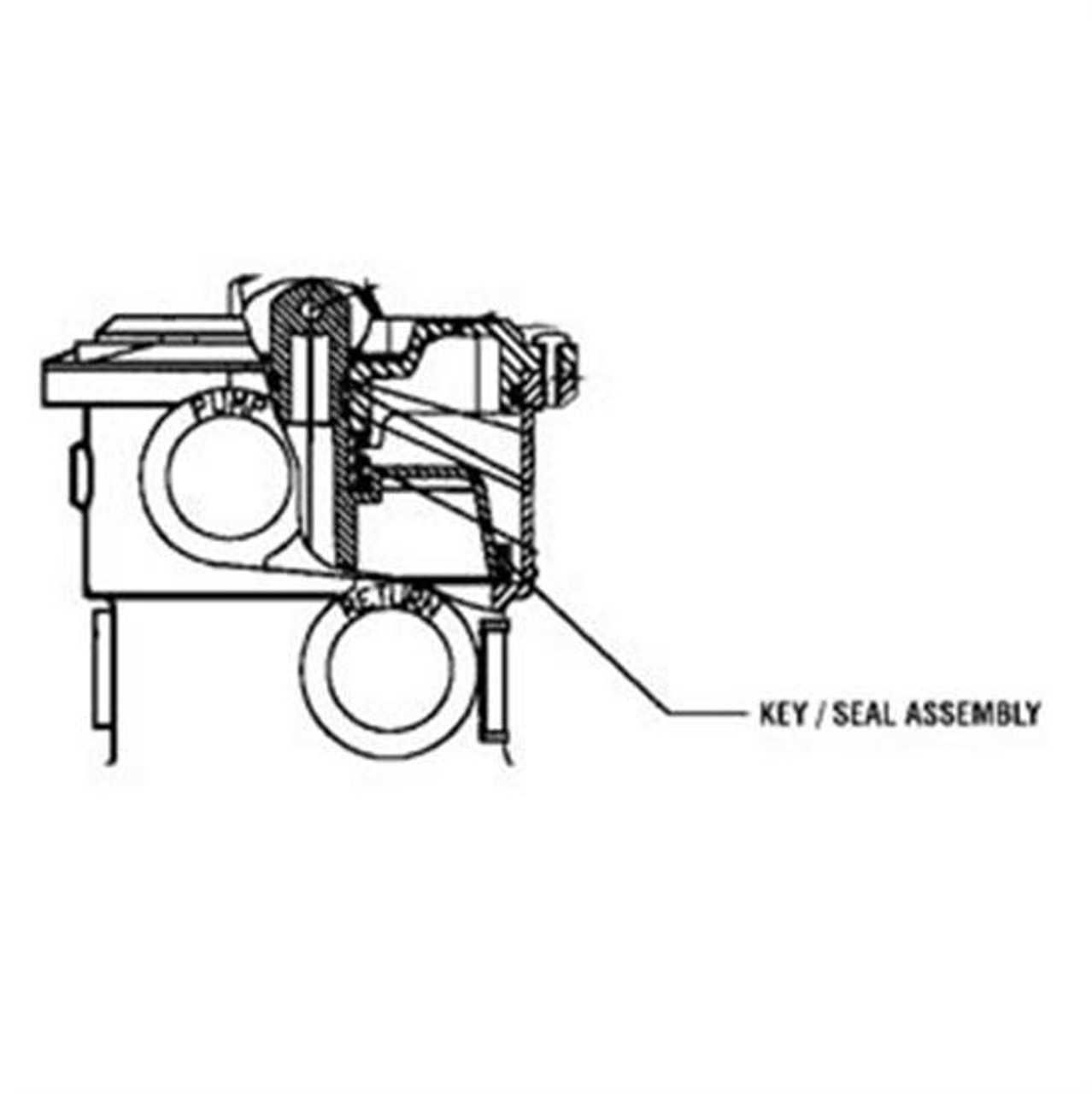

Detailed visual references help to clearly depict the assembly, providing clarity when repairs or replacements are required. These insights will guide you through the process of understanding each part’s role in the broader system.

Understanding the Pool Valve Components

To effectively maintain a pool filtration system, it’s important to understand the various components that contribute to its smooth operation. These elements work together to regulate water flow and ensure the proper functioning of the system. Each part serves a specific purpose and contributes to the overall efficiency of the mechanism.

The key components of the valve include valves, seals, and levers, which enable users to control the direction of water flow. These elements must be well-maintained to avoid malfunctions that could disrupt the entire system. Proper identification of these components will aid in diagnosing issues quickly, ensuring minimal downtime for repairs.

Each component’s design and structure are tailored to provide durability and ease of use, allowing for smooth operation over time. Understanding their layout helps to spot wear and tear, making it easier to replace damaged parts before they lead to bigger problems.

How to Read the Components Layout

Interpreting a visual representation of a system’s elements requires understanding the symbols and connections that indicate how each part fits into the whole structure. A clear understanding of these symbols will allow users to quickly identify individual components and their relationships within the mechanism. This skill is essential for efficient troubleshooting and repair.

Identifying Key Elements

The layout typically includes numbered labels that correspond to specific components, allowing users to easily match them to their physical counterparts. Understanding the orientation and placement of these components ensures accurate identification and replacement.

Understanding Connections and Functionality

In addition to individual parts, the diagram often illustrates how these components interact with each other. By following the lines and symbols that represent connections, users can gain insight into how each part contributes to the overall system’s function. Recognizing these relationships is crucial for diagnosing issues and performing repairs.

Common Issues and Replacement Parts

Even the most reliable systems can experience wear and tear over time, leading to various issues that may require the replacement of certain components. Identifying these problems early is key to avoiding more serious damage and ensuring that the equipment continues to function properly. Recognizing common faults and understanding the necessary replacements will help you maintain the system effectively.

Frequent Problems and Causes

- Leaks: Seals or gaskets may degrade, leading to water leaks around the valve assembly.

- Improper Flow: Obstructions or malfunctions in the valve mechanism can hinder the flow of water, affecting the system’s efficiency.

- Corrosion: Metal components can corrode over time, weakening the structure and compromising its function.

Essential Replacements

- Seals and O-rings: These rubber components are crucial for preventing leaks and maintaining tight connections.

- Levers and Handles: Over time, these parts can become worn or broken, requiring replacement for smooth operation.

- Valve Internals: The internal mechanism of the valve can become faulty, requiring complete internal replacements for proper function.