Understanding the structure of heavy machinery is crucial for effective maintenance and repair. Knowing where each part fits and how they interact can help improve the longevity and efficiency of your equipment. The layout of various components offers a roadmap for troubleshooting and servicing complex machines.

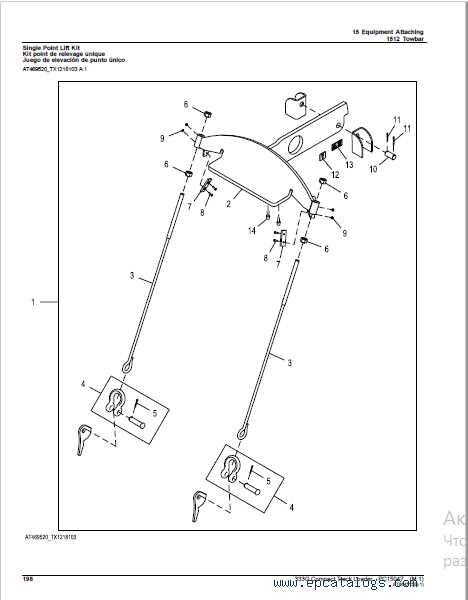

When you have a clear visual representation of all the main elements, it becomes easier to spot issues and plan repairs. Having detailed schematics at your disposal is a valuable tool for both professionals and enthusiasts. These layouts simplify the process of identifying wear and tear or other mechanical issues before they become significant problems.

In this guide, we will explore the essential features of an advanced machine layout, helping you to better understand its components. Whether you’re working on routine maintenance or need to make critical repairs, this information will serve as a foundation for your tasks. Understanding these systems is key to ensuring smooth operation and preventing costly downtime.

Understanding the Excavator Component Layout

Knowing the layout of a machine’s individual elements is essential for efficient operation and troubleshooting. The proper arrangement of components ensures seamless functionality, while also making it easier to detect faults and perform necessary repairs. A well-organized blueprint of the system allows operators to quickly identify parts that may require attention, reducing downtime and improving maintenance efficiency.

The layout provides a visual guide that connects various machine elements, showing how they work together. Whether you’re performing regular checks or handling a specific issue, understanding the layout helps ensure that you’re targeting the correct areas for repair or replacement. Below are some of the main groups of components typically found in such layouts:

- Hydraulic System: Critical for operation, including pumps, valves, and hoses.

- Powertrain: Includes the engine, transmission, and related drivetrain components.

- Chassis and Frame: The foundational structure that holds everything together.

- Electrical System: Wiring, sensors, and controllers for machine functionality.

- Attachment Components: Arm, bucket, and other essential parts for digging or lifting tasks.

Each of these components plays a specific role, and the layout allows you to see their interconnection and individual functions. When repairs are needed, the layout helps guide you to the root cause of the problem, making the task more straightforward and efficient.

In addition to providing a useful reference for troubleshooting, such layouts are also essential for performing maintenance tasks such as fluid checks, lubrication, and wear inspections. Knowing exactly where each component is located and how they interact can significantly improve the accuracy and speed of these tasks.

How to Identify Key Components on the Layout

Recognizing the primary elements of a machine layout is crucial for effective troubleshooting and repair. By carefully studying the visual representation of the system, you can pinpoint each component’s location and understand its role in the overall operation. This section will guide you through the process of identifying essential machine parts on a layout.

Start with the Core Systems

The first step in identifying key components is to focus on the machine’s core systems. These systems are often the most vital for machine operation and should be easily distinguishable on the layout. Look for major units such as the engine, hydraulic pumps, transmission, and electrical systems. These areas often take up a central position in the diagram, making them easier to spot.

Look for Labels and Groupings

Many layouts include labels, color codes, or numbered groupings that help identify the different parts of the system. These visual cues are incredibly helpful when you’re trying to locate a specific component. For instance, you may find groupings that separate hydraulic components from the engine system or highlight the electrical connections. Paying attention to these features will help you quickly navigate the layout and identify what each section represents.

Once you’ve identified the core systems and used the labels to locate different components, the next step is to assess the individual parts within each system. By understanding how each element functions within its group, you can more easily diagnose issues and perform maintenance tasks as needed.

Maintenance Tips Using the Layout

Utilizing a detailed layout can significantly improve the efficiency of maintenance tasks. By referring to the layout during inspections or repairs, you can ensure that no component is overlooked. This section offers essential tips on how to use the layout to streamline your maintenance routine and keep your machine running smoothly.

One of the most effective ways to use the layout is to perform regular visual checks. Before starting any maintenance, identify critical systems like the hydraulic, powertrain, and electrical groups. Inspecting these systems early can help you catch any issues before they become more serious. The layout provides a clear guide for knowing where to focus your attention first, ensuring a thorough check.

Another important tip is to use the layout when ordering replacement parts. Understanding the exact location and specifications of a component makes it easier to order the correct part. Instead of relying on general descriptions or vague terminology, you can refer directly to the layout to identify part numbers and other key details, ensuring accurate orders and reducing the chance of errors.

Lastly, use the layout as a guide for preventive maintenance. Regularly scheduled maintenance tasks such as fluid checks, cleaning, or lubricating specific components can be performed more efficiently when you know exactly where each part is located. Following the layout ensures that no area is neglected and helps maintain optimal performance.