htmlEdit

When it comes to agricultural machinery, having a clear understanding of the various elements that make up the system is essential for ensuring smooth operation. Proper knowledge of these components not only aids in troubleshooting but also enhances the overall performance and longevity of the equipment.

Regular maintenance is crucial for keeping the machine functioning efficiently. Knowing the key parts and their specific roles allows for more effective care, helping to prevent breakdowns and costly repairs. It’s important to have access to a detailed overview that shows where each part fits within the entire mechanism.

In this section, we will explore how to identify the critical components of this agricultural tool and provide insight into accessing relevant guides for replacements and repairs. Whether you are performing routine checks or addressing specific issues, understanding the structure of the system will ensure you can maintain peak performance over time.

htmlEdit

Understanding the Equipment Structure

In any complex agricultural machinery, recognizing how each element interacts within the overall system is crucial for effective operation. The structure is designed with a combination of parts that work together to ensure the device performs optimally under various conditions. Each component plays a specific role in maintaining the balance and functionality of the machine.

Knowing the layout of the key elements allows for easier identification of potential issues during maintenance. Whether you are performing routine checks or addressing a malfunction, being familiar with how everything fits together ensures you can act promptly and efficiently. This knowledge empowers users to handle repairs or replacements when necessary.

By focusing on the various sections of the system, one can gain insight into how individual elements contribute to the machine’s overall performance. This understanding not only helps with troubleshooting but also improves the ability to maintain the equipment in peak condition over time.

htmlEdit

Key Components and Their Functions

The efficient operation of agricultural equipment relies on the coordination of numerous essential components. Each piece has a specific role, contributing to the overall functionality of the machine. Understanding the function of these elements helps ensure the system runs smoothly and any issues can be quickly identified and addressed.

- Power Transmission System: Transfers energy from the engine to various moving parts, allowing the machinery to perform its intended tasks.

- Cutting Mechanism: The heart of the machine, this system is responsible for cutting and processing materials, ensuring clean and efficient work.

- Support Frame: Provides structural stability, allowing all components to work together without compromising safety or efficiency.

Each of these crucial components works in tandem with others, enabling the machinery to operate as a cohesive unit. Regular maintenance and familiarity with their functions help optimize performance and prevent unnecessary downtime.

htmlEdit

Identifying Replacement Parts for Maintenance

Maintaining agricultural equipment in peak condition requires understanding when and where to replace worn-out elements. Identifying the right components for replacement ensures that the machine continues to operate effectively and efficiently. Regular inspections help pinpoint areas that need attention and avoid costly breakdowns during operation.

Steps to Identify Worn-out Components

First, it’s important to regularly check for signs of wear, such as cracks, rust, or loss of functionality. Some key components, like blades or belts, may show visible signs of damage. When these are identified, refer to the machine’s manual or a trusted guide to find exact replacements.

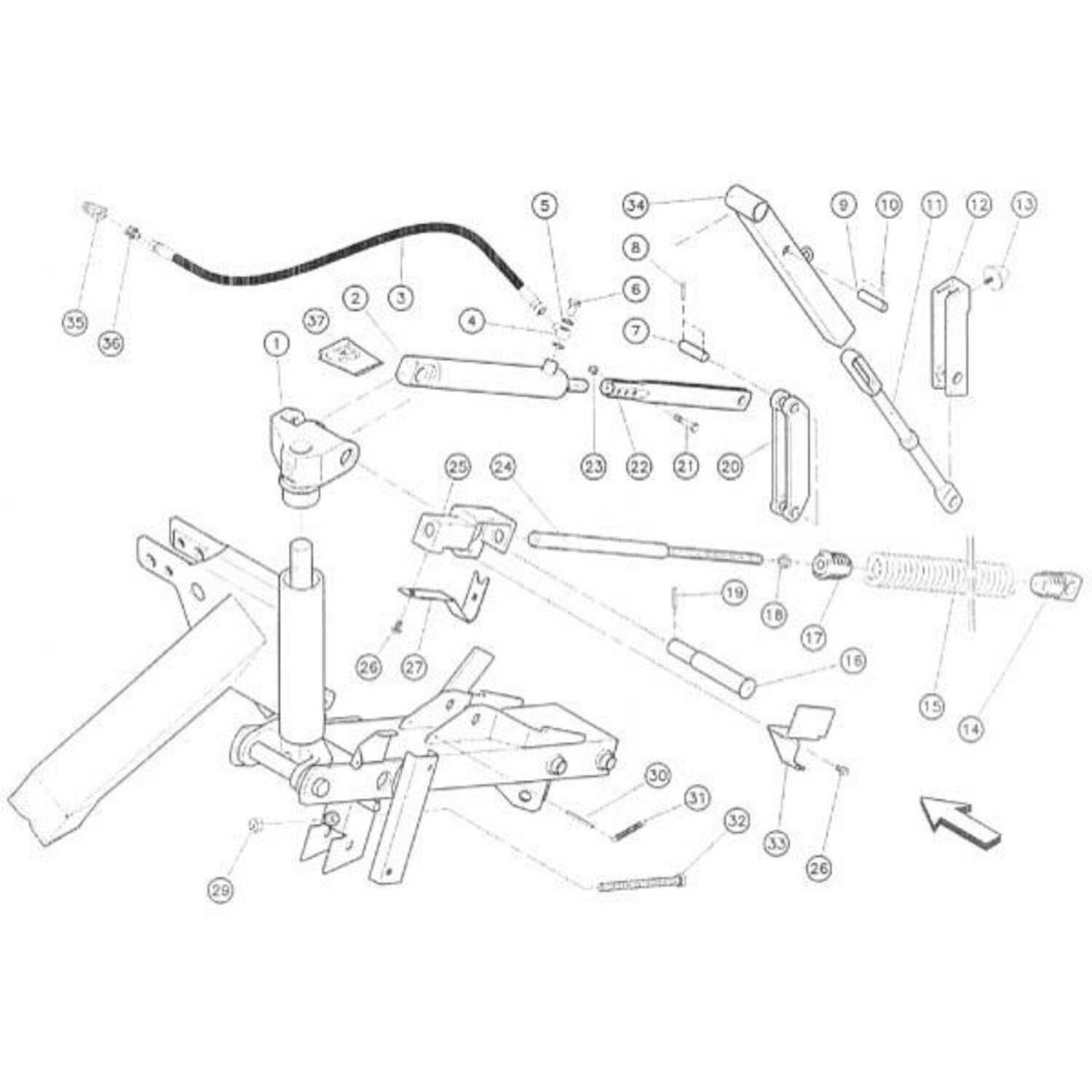

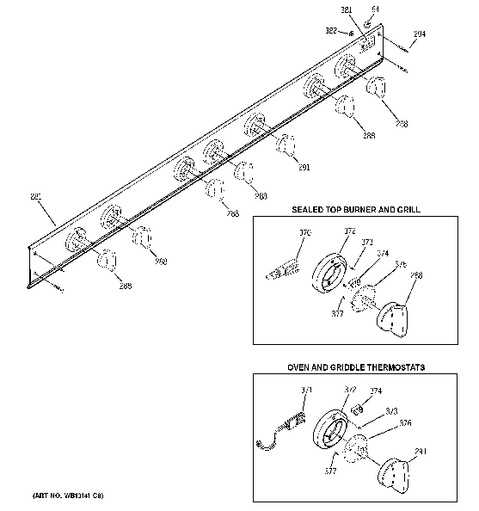

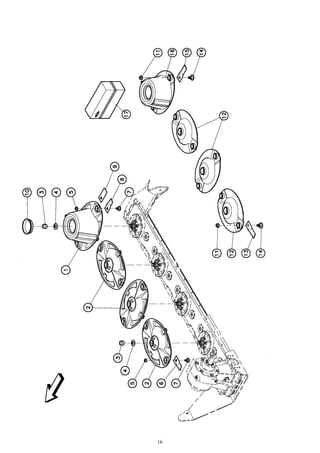

Using Diagrams for Accurate Identification

Detailed visual guides can be helpful in recognizing the specific components that need to be replaced. These diagrams often highlight each element, making it easier to match the damaged part with the correct replacement. Having access to such resources can save time and ensure accuracy during the replacement process.

Proper identification and replacement of components is essential for extending the life of the equipment. Taking time to carefully assess the condition of each part will ensure continuous and efficient operation, minimizing downtime and maximizing productivity.

htmlEdit

How to Access the Parts Diagram

To effectively maintain and repair agricultural machinery, having a clear visual representation of its structure is essential. Accessing detailed illustrations of the equipment can simplify the identification of components and ensure you choose the correct replacements. This process allows for more efficient repairs and helps avoid costly mistakes.

There are several ways to access these detailed visual guides. Most manufacturers provide online resources where users can find digital versions of these illustrations. Additionally, hard copies may be available in the equipment’s manual or through customer support channels.

Using these resources, you can navigate through various sections of the equipment, pinpointing each individual element. With this information, you can confidently address any maintenance needs or order the necessary replacements without confusion.

htmlEdit

Maintaining Optimal Performance of Agricultural Equipment

To keep agricultural machinery running smoothly, regular maintenance and proper care are essential. By following a structured maintenance routine, you can ensure the equipment performs at its best, reducing the likelihood of unexpected breakdowns and improving its lifespan. Key practices involve checking, cleaning, and replacing worn-out components as needed.

| Maintenance Task | Recommended Frequency | Notes |

|---|---|---|

| Check blade sharpness | After every use | Ensure blades are free from damage and maintain sharp edges for efficient cutting. |

| Lubricate moving parts | Every 50 hours of operation | Reduces friction and ensures smooth movement of components. |

| Inspect belts and tension | Every 100 hours of operation | Check for wear and adjust tension to prevent slippage. |

By adhering to these regular maintenance tasks, you can enhance the equipment’s overall performance. Proper care also ensures the machinery runs efficiently, minimizing fuel consumption and operational costs while increasing productivity on the field.