When it comes to keeping your outdoor spaces neat and tidy, having a clear understanding of the components that make up your lawn care equipment is essential. Knowing how each element fits together and functions can make repairs and maintenance a simpler process. Properly maintaining your tools helps extend their life and ensures they work at their best for every use.

Whether you’re dealing with a powerful cutting machine or another type of lawn tool, identifying the different parts can seem overwhelming. However, once you familiarize yourself with the key pieces and their functions, troubleshooting becomes much easier. Visual aids are incredibly useful for this purpose, offering a clear overview of all the essential components and their interconnections.

In this guide, we will explore how to interpret such references and provide practical tips on repairing and maintaining your equipment. Understanding these basic elements can help prevent breakdowns and ensure your gear is ready for action whenever you need it.

Understanding Lawn Equipment Components

Every lawn care tool is made up of various elements that work together to ensure smooth operation. Familiarity with each component allows you to troubleshoot problems, perform maintenance, and make repairs when necessary. By identifying the key parts of your device, you can gain a better understanding of how everything functions and how to keep it running efficiently.

Key Functional Elements

The core components of a lawn care machine include the engine, drive system, and cutting mechanism. These parts play a crucial role in delivering power, movement, and precision cutting. The engine is the powerhouse, converting fuel into energy, while the drive system transfers that energy to the cutting blades. The cutting mechanism is responsible for achieving the desired result, whether it’s a precise cut or a more rugged trimming job.

Maintenance and Replacement Considerations

Regular maintenance is vital for keeping your machine in optimal condition. Over time, certain components may wear down or become damaged, requiring replacement. Identifying these parts early can help you avoid more costly repairs in the future. Some of the most commonly replaced elements include the cutting head, air filter, and spark plug. Regular inspection and cleaning will ensure each piece continues to function as intended, providing consistent performance season after season.

How to Read a Parts Reference Guide

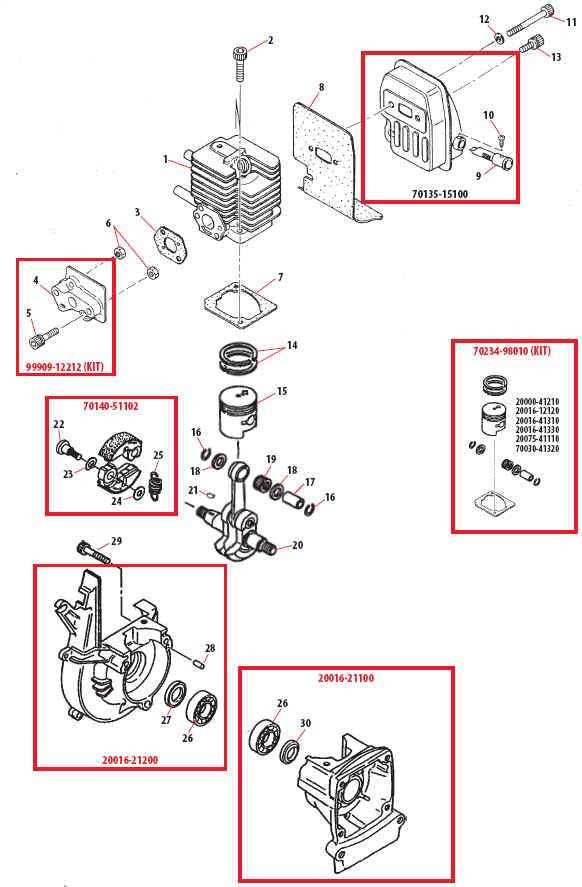

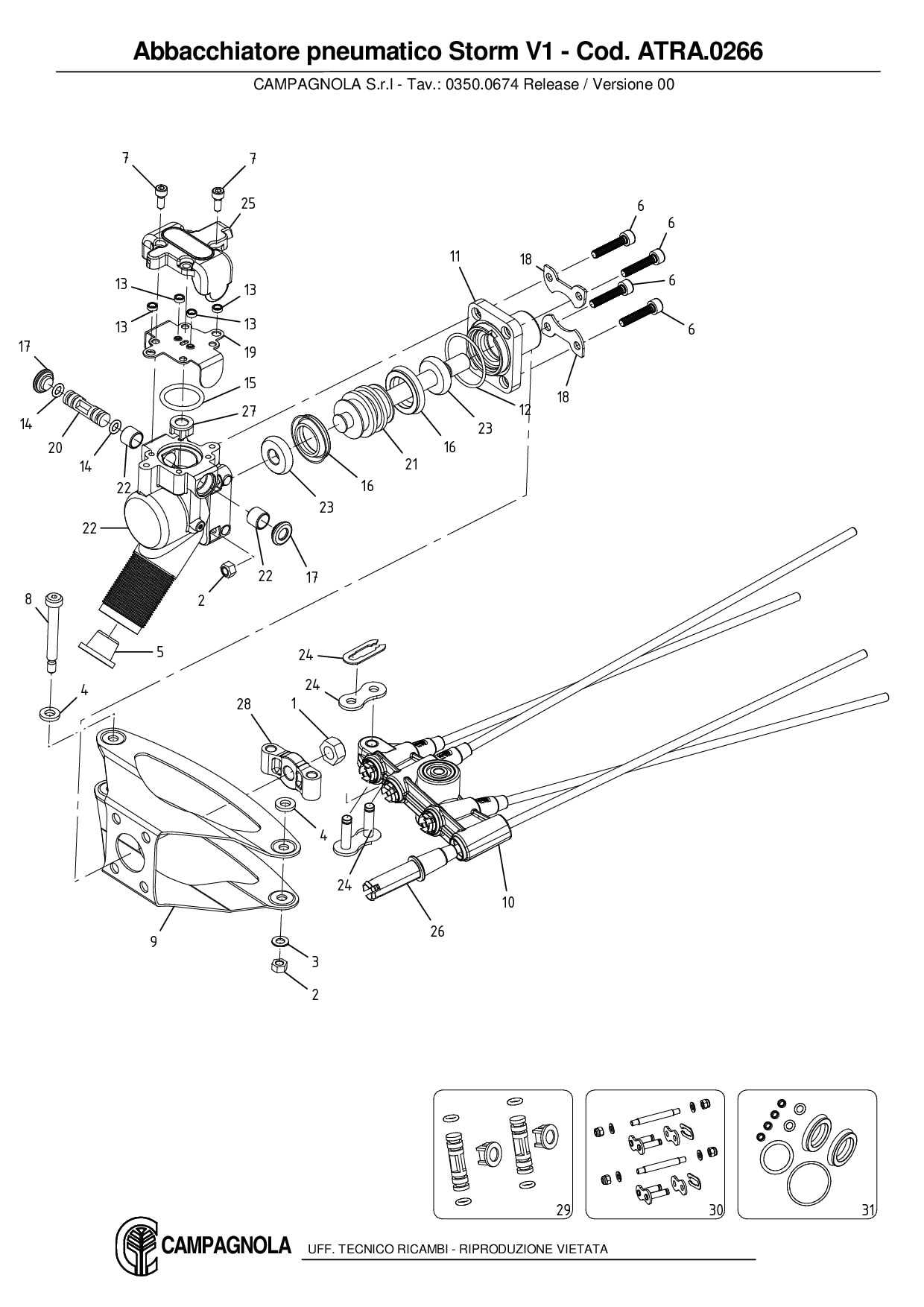

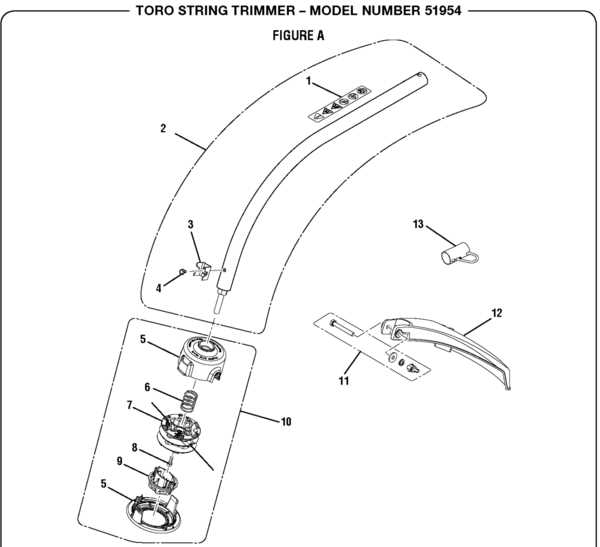

Understanding how to interpret a tool’s reference guide is essential when performing maintenance or repairs. These guides offer a visual representation of the internal components, their placement, and their interconnections. By familiarizing yourself with the layout and symbols used, you can easily identify each part, ensuring that any replacement or repair is done with precision and accuracy.

Breaking Down the Components

Each section of the reference guide typically corresponds to a specific area of the machine. The components are often labeled with numbers or letters, which are matched with a list that provides detailed descriptions. Pay attention to the orientation of the parts, as the diagram may be designed from a specific angle to provide a clearer view of internal mechanisms. Understanding this will help you visualize how the parts work together and make it easier to locate the ones that need attention.

Using the Reference for Repairs

Once you identify the part that needs repair or replacement, the guide can help you find the exact specifications or model number to ensure compatibility. In some cases, the diagram will also provide maintenance tips, such as lubrication points or cleaning instructions. With these references, you can tackle repairs with confidence, minimizing the risk of mistakes and maximizing the efficiency of the repair process.

Common Lawn Tool Component Replacements

Like all outdoor equipment, your lawn care tools require periodic replacement of key components to maintain optimal performance. Over time, certain parts may wear down or become damaged, leading to decreased efficiency or functionality. Knowing which parts commonly need replacing can help you keep your equipment in top shape and avoid costly repairs.

Cutting Head and Blades

The cutting head and blades are among the most frequently replaced components. With constant use, these elements can dull or break, impacting cutting performance. Regularly inspecting and replacing the cutting head ensures that the machine can perform its job effectively, providing clean and precise cuts every time.

Air Filter and Spark Plug

The air filter and spark plug play a crucial role in maintaining the engine’s performance. Over time, the air filter can become clogged with dirt and debris, reducing airflow and engine efficiency. Similarly, a worn-out spark plug can lead to starting issues and poor engine performance. Replacing these parts regularly ensures smooth operation and helps prevent more serious engine problems down the line.