Understanding the intricate details of your marine engine is essential for proper maintenance and efficient performance. Knowing the layout and function of each element allows you to troubleshoot effectively and ensure longevity. With the right information, you can confidently approach any issue that may arise during operation.

By familiarizing yourself with the key parts and their relationships, you gain the ability to perform repairs and upgrades independently. This knowledge empowers you to avoid costly repairs and maintain your vessel in optimal condition. The detailed visual reference provided serves as a valuable tool for anyone working with or servicing marine engines.

Proper maintenance is critical for safety and performance, and recognizing potential problems before they escalate can save both time and money. Whether you’re a seasoned expert or a novice, understanding the engine structure and its components is the first step toward ensuring your vessel runs smoothly and efficiently.

Understanding Marine Engine Components

Every marine engine consists of a variety of interconnected elements, each serving a specific function to ensure smooth and efficient operation. These components range from mechanical parts responsible for movement to systems that regulate power and cooling. A comprehensive understanding of these elements is crucial for identifying issues, performing maintenance, and improving overall engine performance.

Familiarizing yourself with the engine’s internal structure helps in recognizing how each part contributes to the overall functionality. From the transmission and propellers to the cooling systems and fuel components, understanding their roles and interactions enables more precise troubleshooting and better maintenance practices. This knowledge is essential not only for professionals but also for enthusiasts looking to maintain their equipment independently.

By studying the layout and roles of these components, you can diagnose problems more effectively and perform necessary repairs with confidence. Whether you’re dealing with routine maintenance or more complex issues, knowing what each part does and how it fits into the bigger picture ensures that your engine operates at its best.

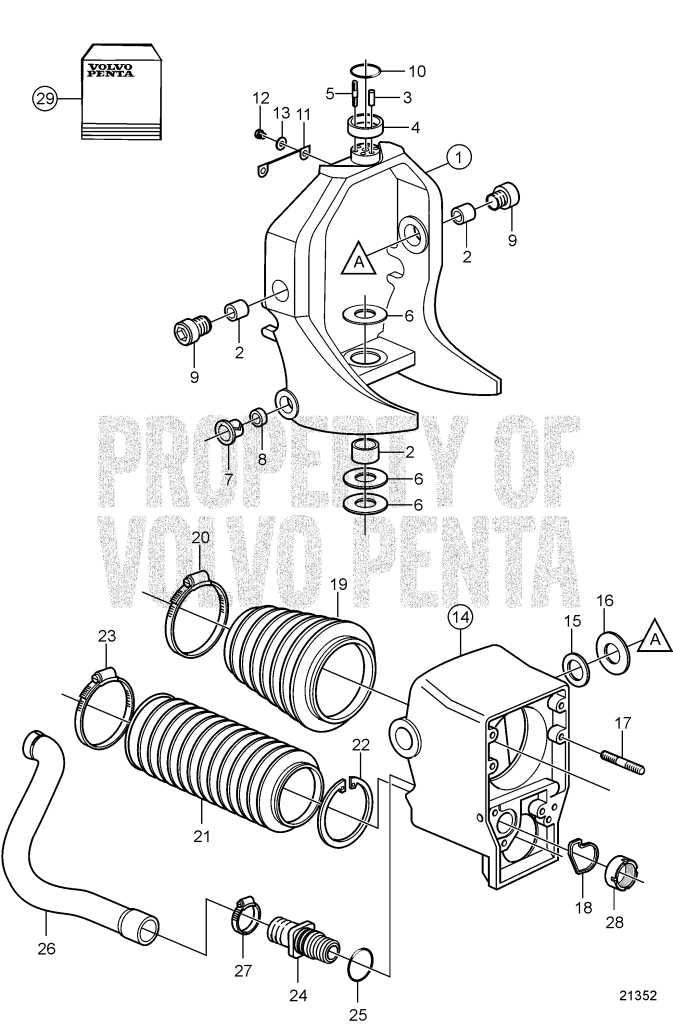

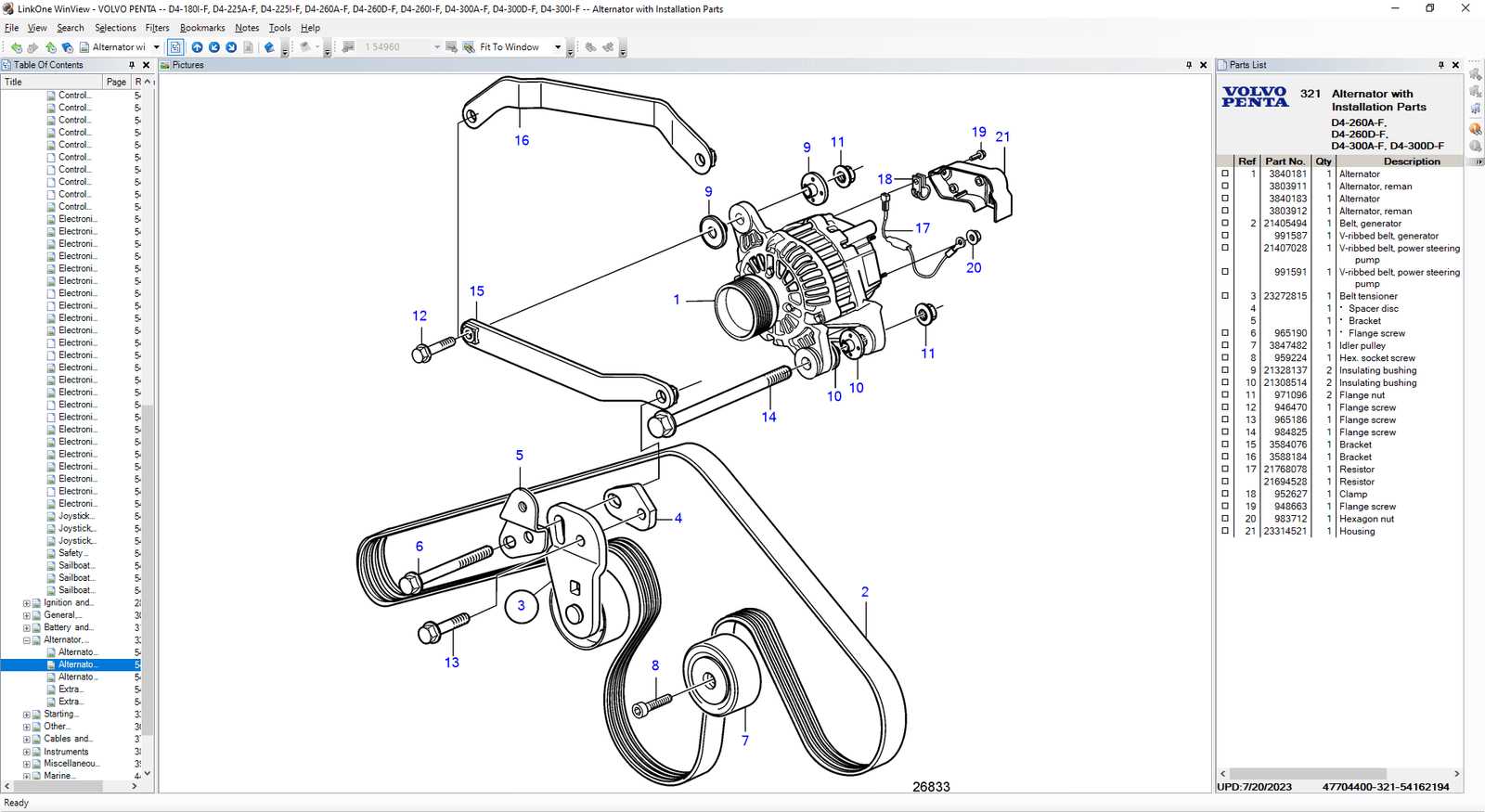

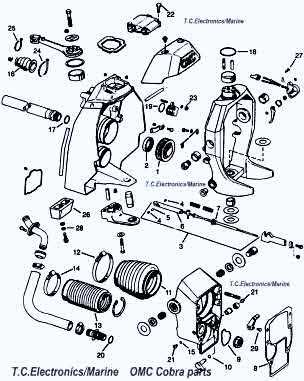

How to Use the Parts Diagram

Using a visual reference for engine components provides a clear understanding of their arrangement and functionality. This tool allows you to quickly identify specific elements, their location, and how they connect within the engine assembly. By consulting such a reference, you can ensure accurate diagnostics and repairs, avoiding unnecessary disassembly or confusion.

Identifying Key Components

Start by focusing on the key parts that make up the engine’s core systems. Each component is typically labeled for easy identification, helping you to trace any issues to their source. Whether you need to inspect the propulsion system, cooling mechanisms, or fuel delivery systems, having a visual guide ensures you don’t overlook any important details.

Following the Assembly and Disassembly Process

A well-organized reference also guides you through the step-by-step process of assembling or disassembling the engine. By following the visual layout, you can avoid errors during reassembly and ensure that all components are properly positioned. This step-by-step approach also minimizes the risk of damaging fragile parts or losing small components in the process.

Common Issues and Maintenance Tips

Every mechanical system is prone to wear and tear over time, and marine engines are no exception. Regular maintenance and early detection of issues can prevent more serious problems from arising. Understanding common failures and knowing the proper upkeep methods helps ensure your engine remains reliable and efficient, extending its lifespan.

Frequent Mechanical Failures

Some of the most common issues include problems with the propulsion system, such as worn-out seals or damaged gears. These can cause a loss of power or irregular movement. Another frequent issue is overheating due to clogged cooling passages or malfunctioning thermostats, which can lead to engine damage if not addressed promptly. Identifying these problems early on ensures that repairs are less costly and prevent further damage to other systems.

Essential Maintenance Practices

To maintain optimal performance, regular inspections are crucial. Check fluid levels and replace them when necessary, especially for the engine oil and cooling fluids. Clean or replace filters to avoid blockages, and inspect belts and hoses for signs of wear. Additionally, lubricate moving parts regularly to reduce friction and prevent premature failure. Following a consistent maintenance routine will keep the engine running smoothly and help avoid unexpected breakdowns.