When maintaining or repairing machinery, having a clear understanding of its internal components is essential. This helps ensure proper functioning and allows for efficient troubleshooting. Knowing the various elements and their connections can greatly improve the repair process, whether for general upkeep or when dealing with specific issues.

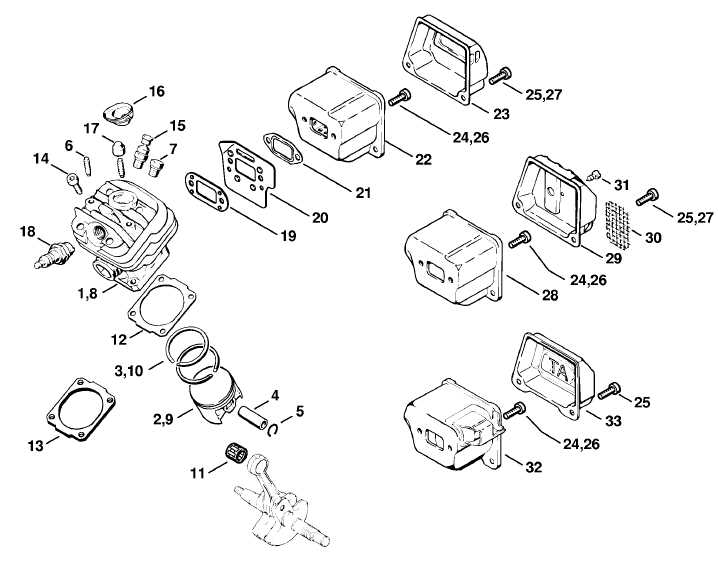

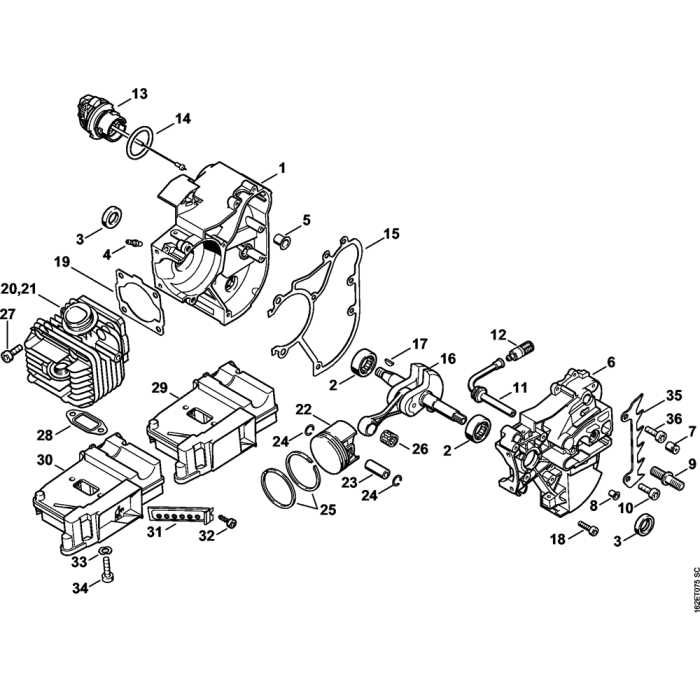

One crucial aspect of this understanding is the ability to interpret and use visual aids that highlight the arrangement of these components. These visual guides provide a detailed look at each part, helping users identify the right pieces quickly and with confidence. Clear and accurate schematics are invaluable tools for any repair project.

By familiarizing yourself with the arrangement of the system’s components, you can make informed decisions about replacements and repairs. With this knowledge, the entire maintenance process becomes more manageable, ensuring your equipment stays in optimal condition for years to come. Efficient use of resources is key to successful upkeep and performance.

Understanding Key Components of Your Equipment

Knowing the main components of your equipment is crucial for effective maintenance and repair. Each part plays a specific role in ensuring the machine operates smoothly and efficiently. Identifying these elements helps in diagnosing problems, making the repair process much quicker and easier.

By examining the structure and function of the individual components, users gain a deeper understanding of how the system works as a whole. This knowledge allows for more accurate troubleshooting, making it easier to pinpoint issues and address them before they cause major disruptions.

Familiarity with these essential elements enables users to confidently perform routine checks and adjustments. Whether replacing worn-out pieces or adjusting settings for optimal performance, understanding how each part fits into the system ensures longevity and better functionality. Proper care leads to smoother operation and minimizes the risk of unexpected breakdowns.

How to Read the Visual Component Guide

Understanding how to interpret a visual component guide is essential for identifying the specific elements of your machine. These illustrations provide a detailed look at the various parts and their connections, making it easier to identify the exact components you need to inspect or replace. Knowing how to read these guides helps streamline maintenance and repair tasks.

The key to reading these visual aids is focusing on the labels and numbers assigned to each part. These references allow users to quickly locate the corresponding components in the system. Accurate identification of each part is critical for effective repairs and replacements.

Once familiar with the layout and structure, users can follow the guides step by step to identify any faulty components. Understanding the orientation and position of each part within the system ensures that replacements are made correctly, preventing potential damage or complications during repairs. Attention to detail is key when using these guides for successful upkeep.

Key Parts for Maintenance and Repair

Proper upkeep and repair of your equipment require knowledge of its most crucial components. These essential elements play significant roles in ensuring smooth operation and preventing common issues. Recognizing the key parts that often require attention allows for timely maintenance and minimizes the risk of unexpected breakdowns.

The most common parts that require regular maintenance include the engine components, fuel system, and cutting mechanisms. These elements are directly involved in the machine’s overall performance and can wear down over time due to continuous use. Regular inspection and timely replacement of worn-out parts are necessary to maintain efficiency and extend the lifespan of the equipment.

In addition to these critical areas, attention should be given to the electrical and safety components, which are vital for proper operation and user safety. Ensuring that these parts are in optimal condition helps avoid malfunctions and ensures the equipment functions as intended. By focusing on these key components, you can keep your machinery running smoothly and reliably for years to come.