Proper maintenance and repair of outdoor power tools are essential to ensuring their long-term performance. To effectively service your equipment, it’s crucial to have a clear understanding of its internal layout and individual components. This knowledge helps identify any issues, making it easier to replace worn-out or damaged parts.

In this guide, we will break down the critical elements of your tool’s design, showing how to recognize each part and how they contribute to its overall function. By learning how the pieces fit together, you can confidently perform maintenance tasks and address potential problems before they become serious issues.

Knowing the structure of your equipment will not only help you with repairs but also improve its efficiency, keeping it running smoothly for years. Whether you’re a professional or a casual user, this information is invaluable for keeping your machine in top condition.

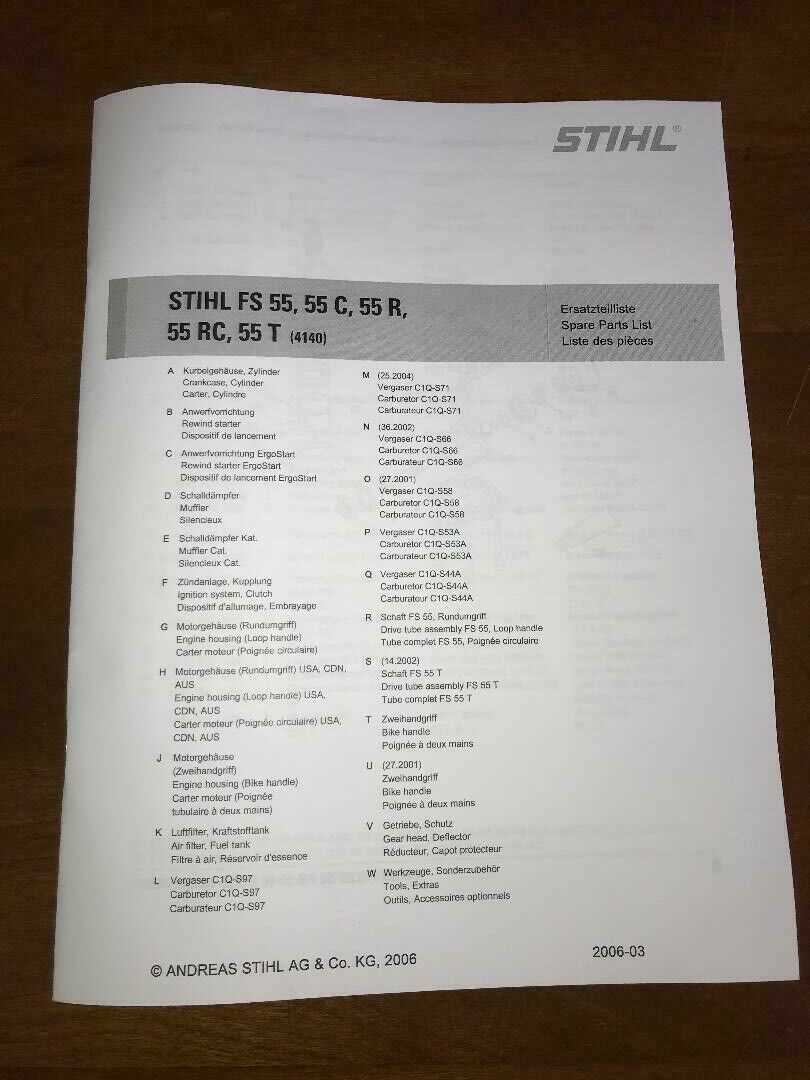

Understanding the Stihl FS 55 Parts Diagram

To ensure that your equipment operates at its best, it’s important to have a comprehensive understanding of its internal structure. This knowledge allows you to recognize and address any issues that may arise. By familiarizing yourself with the key components and their functions, you can perform basic maintenance and repairs with confidence.

Key Components of the Machine

Each tool is made up of several essential elements, each performing a unique function. Understanding how these parts interact will help you troubleshoot and maintain your equipment effectively. Here are some of the most crucial parts:

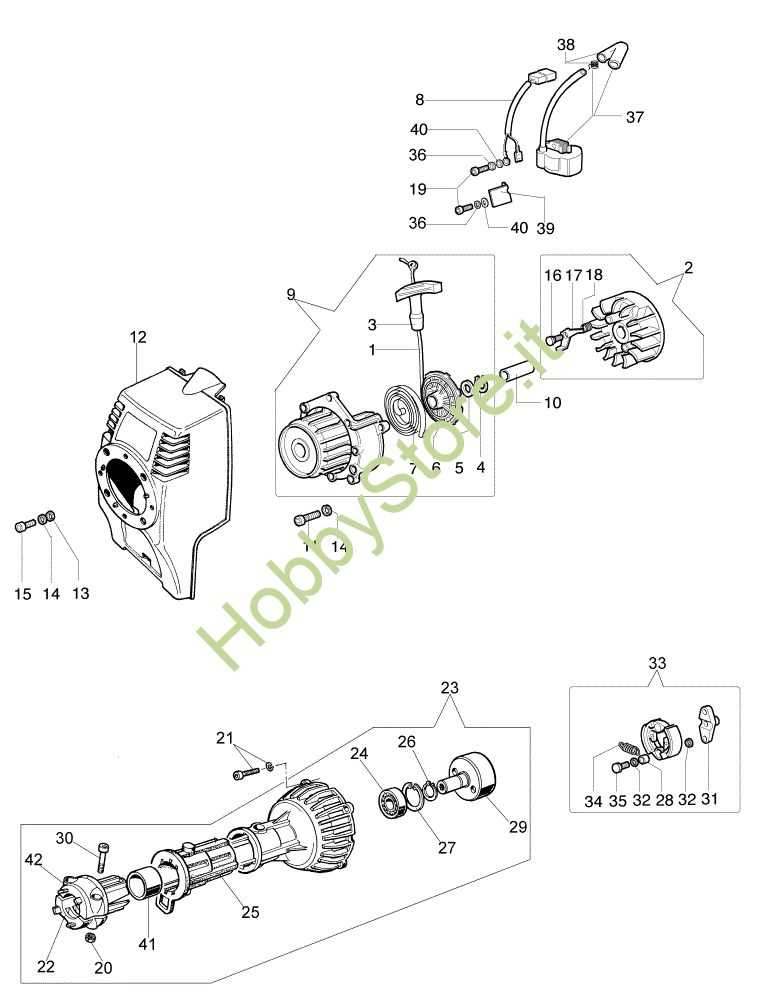

- Engine Components – These are the heart of the machine, responsible for power generation.

- Drive Shaft – Transfers power from the engine to the cutting mechanism.

- Cutting Head – The primary tool for trimming grass and vegetation.

- Handle and Controls – Provide ease of use and allow for precise operation.

How to Use the Diagram for Maintenance

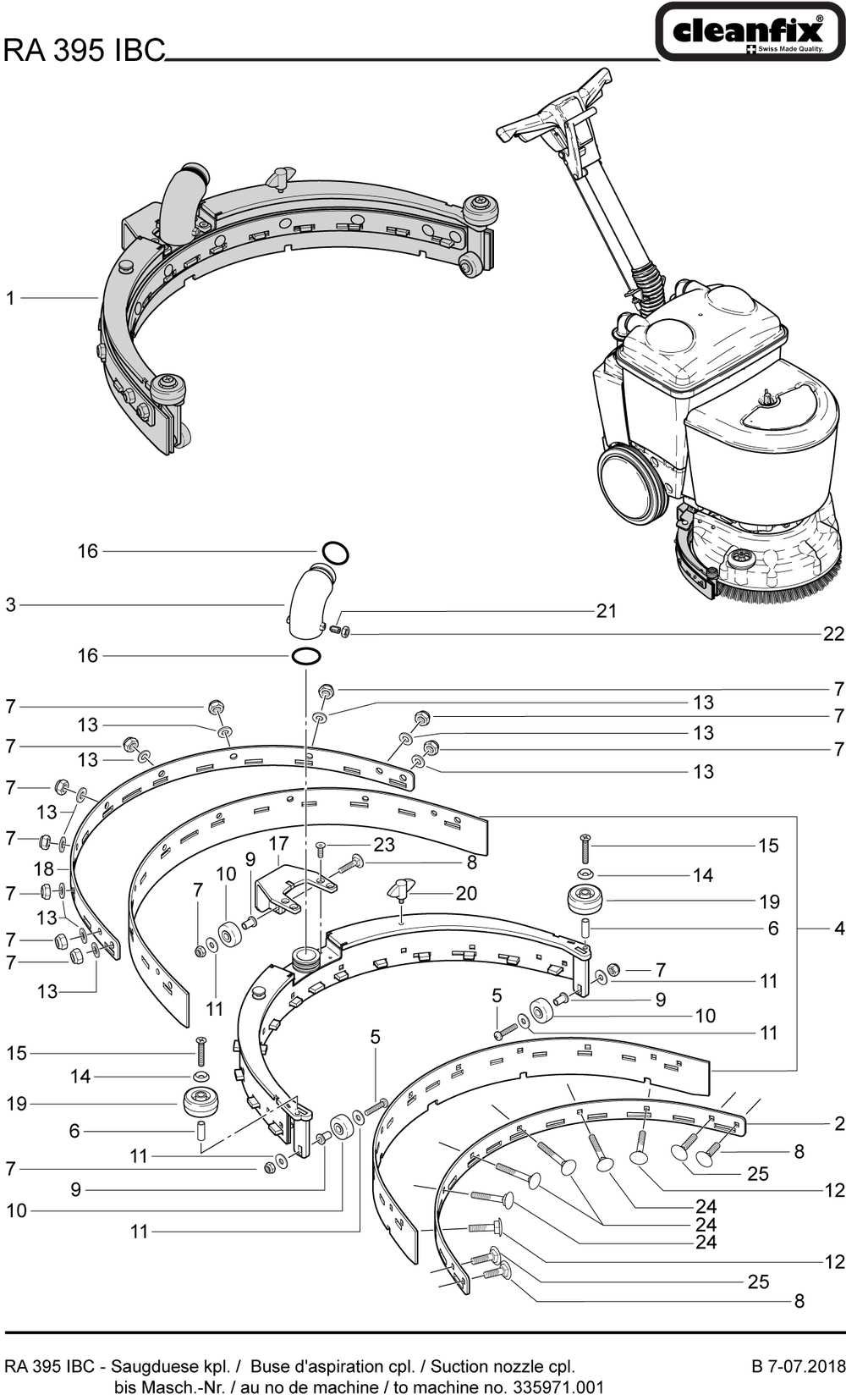

Once you’ve identified the main components, the next step is using the layout to guide your maintenance routine. A clear breakdown of each section allows you to easily locate parts that need attention or replacement. Follow these simple steps:

- Refer to the layout for part identification.

- Locate any components showing signs of wear or damage.

- Replace damaged parts with appropriate replacements.

- Reassemble the equipment and test for proper functionality.

By regularly consulting the visual reference, you can ensure the longevity and optimal performance of your machine. Proper care and attention to detail will help keep your tool running smoothly for years to come.

How to Identify Key Components in the Diagram

Understanding the internal structure of your machine is essential for effective maintenance and troubleshooting. Identifying the crucial elements and their specific functions ensures you can quickly recognize problems and take appropriate actions. By familiarizing yourself with each component, you’ll be able to easily locate what needs attention.

Step-by-Step Component Identification

To begin identifying key elements in the layout, follow these steps:

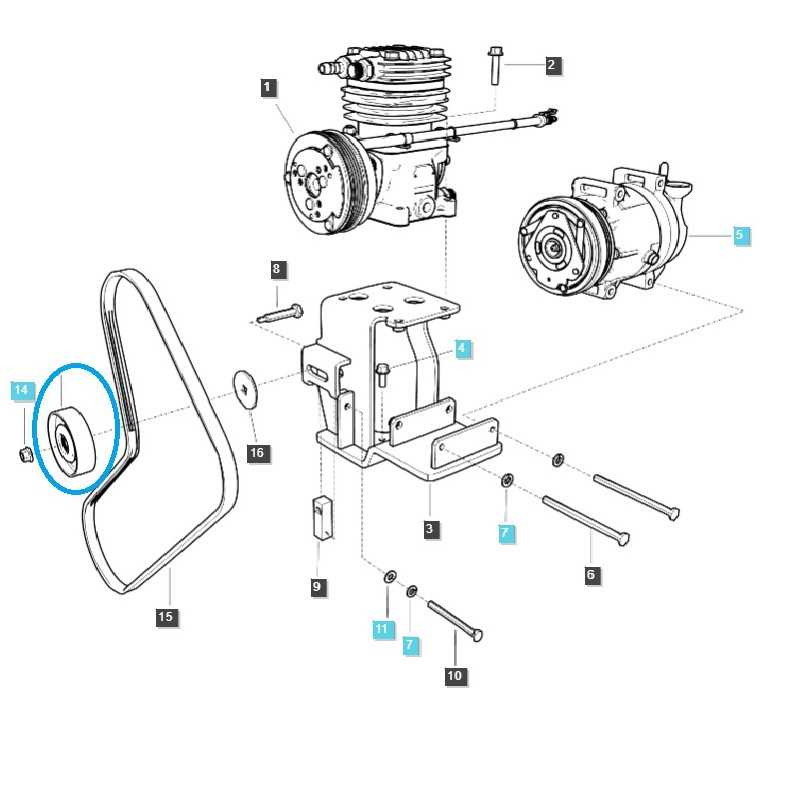

- Start with the Engine – The engine is the core of the system, responsible for generating power. Recognizing its placement will help you trace any issues related to performance.

- Locate the Drive Mechanism – This is responsible for transferring energy to the cutting tools. Understanding this part ensures that you can diagnose issues with power transmission.

- Examine the Cutting Head – The cutting mechanism plays a direct role in the efficiency of the machine. Recognizing this component helps when diagnosing cutting performance problems.

- Identify the Control System – Handles and buttons allow for precise control. Their position and function are critical for proper operation.

Visual Cues for Easy Identification

Once you understand the key components, look for distinctive features that set each part apart. For instance:

- Engine components often have a large, sturdy structure.

- The cutting mechanism is usually located at the front and has rotating blades or lines.

- Control systems will typically be near the handles, often including levers or switches.

With these visual cues, you can quickly identify any part of your tool and address maintenance or repair needs effectively.

Essential Maintenance Tips for Stihl FS 55

Regular maintenance is key to ensuring that your outdoor equipment continues to function efficiently. By performing routine checks and taking proper care of individual components, you can extend the life of your machine and improve its overall performance. Simple maintenance tasks can prevent major issues and costly repairs in the long run.

Routine Cleaning and Lubrication

One of the most important aspects of maintaining your tool is keeping it clean and well-lubricated. This helps prevent dirt buildup and ensures smooth operation. Follow these steps for effective maintenance:

- Clean the Cutting Mechanism – After each use, wipe down the cutting head to remove debris and grass buildup. This will prevent the mechanism from becoming clogged.

- Lubricate Moving Parts – Regularly apply the recommended lubricant to moving parts like the drive shaft and bearings to ensure smooth function and reduce wear.

Component Inspection and Replacement

Inspecting key elements of your machine regularly can help you spot early signs of wear and tear. Pay close attention to:

- Check the Engine – Regularly inspect the engine for any signs of leaks, damage, or excessive wear. Ensure that the spark plug is clean and functioning.

- Examine the Fuel System – Ensure that the fuel lines are free of cracks and the tank is filled with the proper fuel mix.

- Inspect the Handle and Controls – Check that all buttons and handles are securely attached and functioning correctly.

Addressing minor issues promptly can save you time and effort in the future, ensuring that your machine continues to perform at its best.