When dealing with complex machinery, having a clear representation of its internal structure is essential for both maintenance and troubleshooting. A detailed visual guide to the key elements involved in such devices helps technicians and engineers ensure proper assembly and function. Understanding each component’s role and how they interact is crucial for smooth operation.

Each piece of the system plays a vital role, contributing to the overall performance and efficiency of the machine. Recognizing these individual parts and their placement within the structure is the first step toward effective repair or modification.

By carefully analyzing these visuals, professionals can identify potential areas of concern and address issues before they affect the machine’s functionality. This approach minimizes downtime and extends the equipment’s lifespan, making it a valuable resource in industrial and mechanical settings.

Understanding the Mechanical Components

The intricate workings of a mechanical system rely on the precise interaction of multiple elements, each serving a specific purpose. Understanding how these components are designed and positioned is essential for ensuring optimal performance. From structural frameworks to smaller functional elements, each piece plays a crucial role in maintaining the machine’s efficiency.

Key Functional Elements

Each element in the assembly contributes to the overall system by performing specific tasks. These functions range from controlling fluid movement to ensuring stability and regulating pressure within the mechanism. A thorough knowledge of each piece’s role helps identify potential issues and streamline repairs when needed.

Optimal Assembly and Maintenance

Proper assembly and regular maintenance are critical to ensure that all components operate smoothly. An understanding of how each part fits into the system allows for more effective troubleshooting, as well as extending the life of the equipment. Regular inspections and timely replacements are essential for avoiding costly downtime and maintaining reliable operation.

Key Elements of the Mechanical Assembly

Every complex system is made up of several essential elements that work together to ensure the functionality of the entire structure. These components are designed to perform specific tasks and are positioned in a precise arrangement. Understanding each piece’s role and how they interconnect is crucial for maintaining the system’s efficiency and longevity.

Critical Functional Components

The following elements are fundamental for the smooth operation of the system:

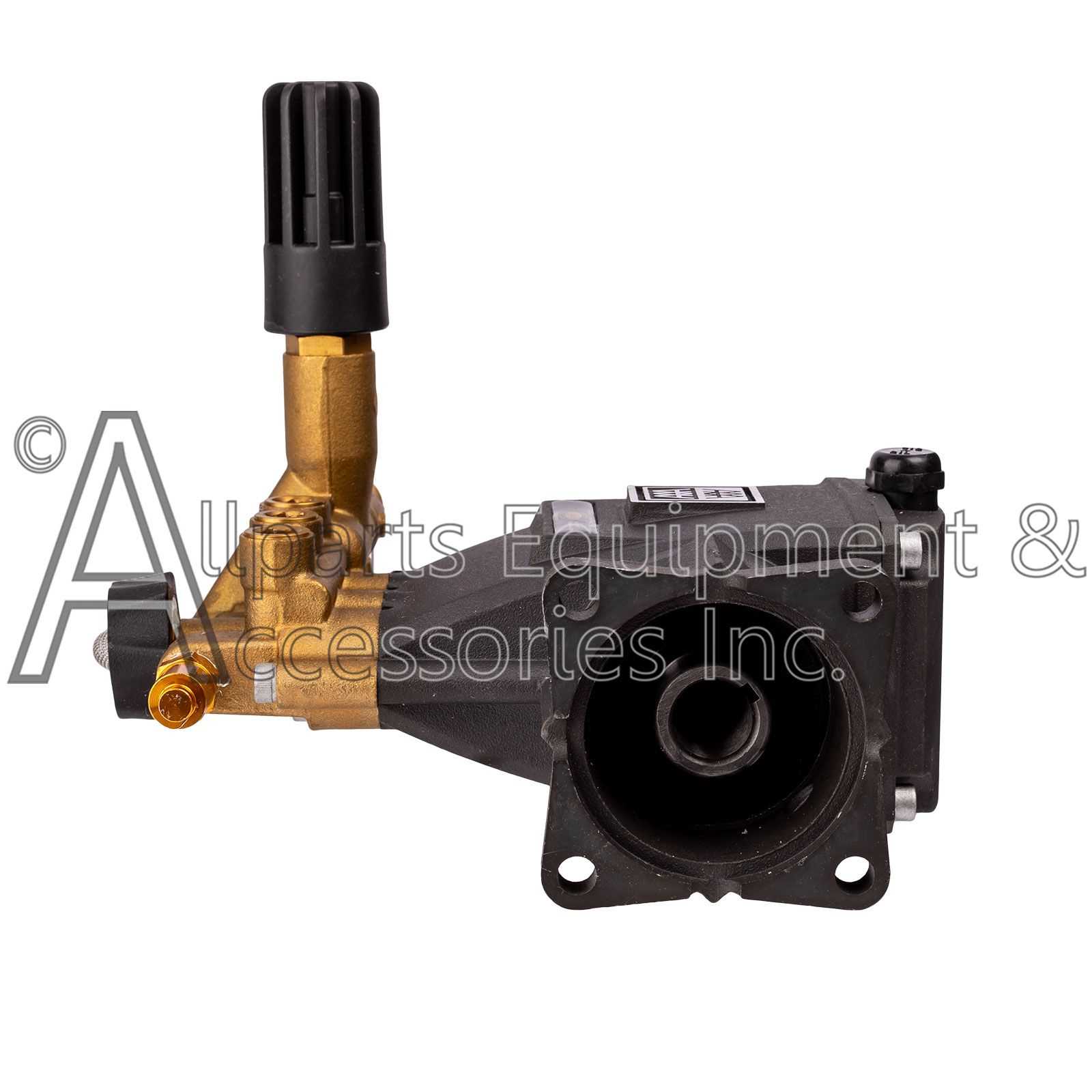

- Control Mechanisms: These regulate the flow and pressure within the system.

- Structural Supports: Components that provide physical stability and hold the assembly together.

- Seals and Gaskets: Prevent leaks and ensure airtight or watertight operation.

Interconnected Parts and Their Functions

Each part plays a specific role, but their effectiveness often depends on how well they work together. The interconnectedness of the following components ensures that the system operates efficiently:

- Fluid conduits that facilitate smooth movement and pressure management.

- Regulatory units that adjust flow and ensure balanced operation.

- Safety valves that prevent overloads and system damage.

Assembly Process of the Mechanical Components

The assembly of complex mechanical systems requires precision and attention to detail. Each element must be carefully positioned to ensure that all functions are properly integrated. Understanding the steps involved in assembling these components is crucial for achieving optimal performance and minimizing the risk of failure.

Step-by-Step Assembly

The assembly process typically follows a structured sequence, ensuring that each element is correctly installed and secured. The steps generally include:

- Initial Positioning: Placing the core framework in its designated space.

- Component Installation: Adding individual pieces like seals, control units, and safety valves.

- Connection Integration: Ensuring that all parts are properly linked to allow smooth operation.

- Final Testing: Verifying the system’s functionality by running tests and checking for any leaks or malfunctions.

Important Considerations

Throughout the assembly process, there are several factors to keep in mind:

- Precision: Accurate placement and alignment of parts are crucial for seamless operation.

- Quality of Materials: Ensuring that only high-quality components are used helps prevent premature wear or failure.

- Lubrication: Proper lubrication of moving parts is essential to reduce friction and prevent damage.