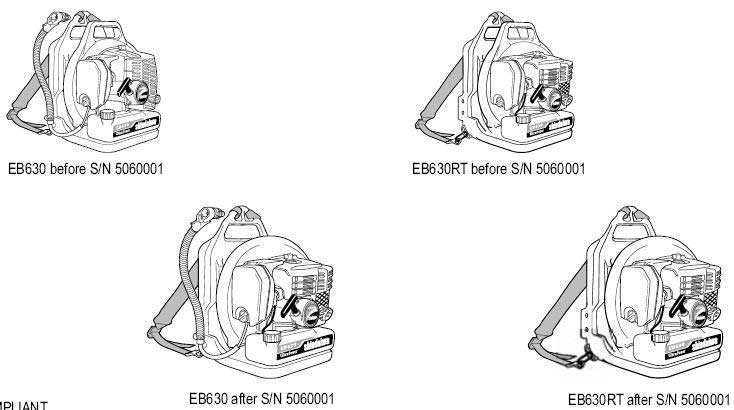

When working with outdoor power equipment, it’s crucial to have a clear understanding of its components and how they interact. Knowing each part’s role allows for efficient repairs and proper maintenance, ensuring that the machine performs optimally over time.

By examining detailed illustrations of the machine’s internal and external elements, users can easily identify specific components, troubleshoot issues, and even replace worn-out parts. This knowledge is especially valuable for those who prefer to handle repairs independently, saving both time and money.

Whether you’re a seasoned professional or a beginner, having a reference to guide you through the various sections and mechanisms of the tool can make a significant difference in its longevity and performance. Proper care and regular maintenance are key to keeping the equipment in top condition for years to come.

Understanding the Equipment Components

Every outdoor tool consists of various elements that work together to perform specific functions. To ensure smooth operation, it is essential to understand how these components fit into the larger system and how they contribute to the tool’s overall effectiveness.

Key Mechanisms and Their Roles

The most critical components include the engine, air circulation system, and controls. The engine serves as the powerhouse, converting fuel into energy to drive the machine. Meanwhile, the air circulation system is responsible for directing airflow, enabling the machine to perform its intended function. The controls allow the operator to manage power and airflow, giving full control over the operation.

Identifying Wear and Tear

Over time, regular use can cause certain components to wear down, affecting performance. Identifying damaged parts early helps prevent further issues and can extend the life of the tool. Routine inspections are essential for detecting these problems, and knowing where each part is located makes maintenance much easier.

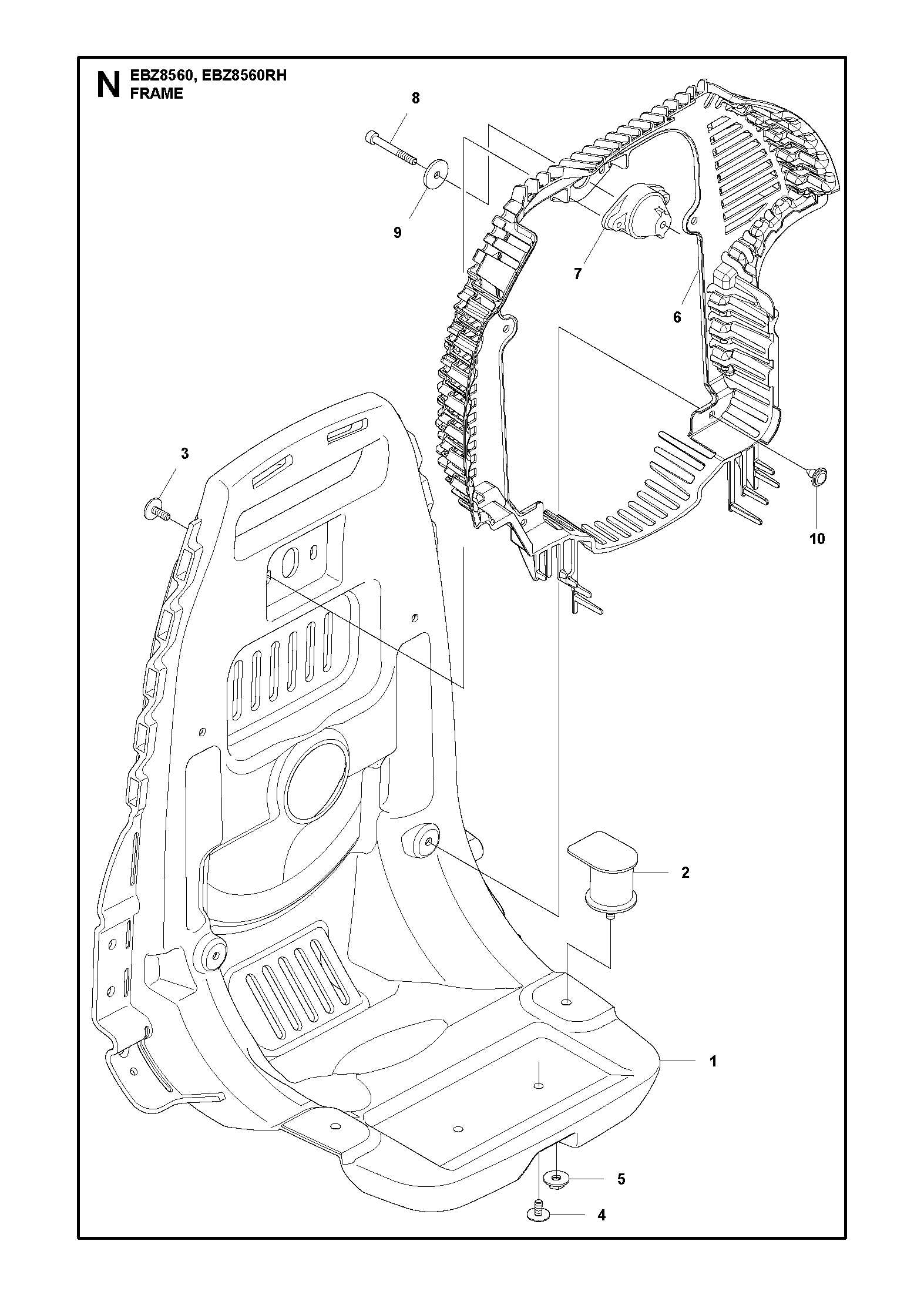

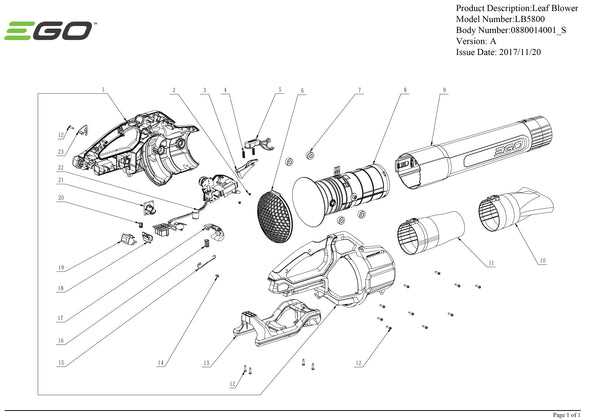

How to Use a Parts Diagram Effectively

Having a clear visual reference of a machine’s internal and external elements can be a game-changer when it comes to repairs and maintenance. It provides a detailed overview of each component, allowing you to identify them quickly and accurately, which is essential for effective troubleshooting and part replacement.

Step-by-Step Guidance

To make the most of a schematic, begin by familiarizing yourself with the layout and section labels. Identify the different parts and their relationships within the system. Start by locating the component you are working on and then trace its connections to the rest of the system. This will give you a clearer understanding of its function and help you spot potential issues more easily.

Common Mistakes to Avoid

One common mistake is focusing too much on one part without considering the entire system. Always view the tool as a whole to ensure that you address any issues that might affect multiple components. Additionally, be sure to cross-reference the schematic with real-world observations to ensure accuracy in identifying worn or damaged parts. Thoroughness is key when using these visual aids.

Common Issues and Troubleshooting Tips

Over time, tools can experience a range of issues that affect their performance. Identifying these problems early and knowing how to address them can save both time and effort. Understanding the typical issues that arise in these machines is crucial for effective troubleshooting and repairs.

One of the most common problems is inconsistent power output. This can be caused by fuel delivery issues, such as clogged filters or a dirty carburetor. To resolve this, ensure that the fuel system is clean and properly maintained. Another frequent issue is improper airflow, which can result from obstructions or wear in the air channels. Checking for debris or damage to the airflow system is vital for restoring optimal performance.

Lastly, difficulty starting the machine is a common complaint. This can be caused by several factors, including a faulty ignition system, a weak spark plug, or fuel-related problems. To fix this, inspect the spark plug for wear and ensure that the fuel is fresh and correctly mixed. Regular maintenance and quick action when problems arise will help keep the tool running smoothly.