Maintaining outdoor machinery is crucial for ensuring long-lasting performance and reliable results. Understanding the essential components of your equipment can help streamline repairs and reduce downtime. Familiarity with each part’s function and structure is key to effective maintenance.

By having a clear understanding of the parts involved, owners can identify issues early and address them before they lead to more costly repairs. This knowledge also aids in sourcing the correct replacements and assembling everything back together with confidence.

Proper care and timely attention to worn or damaged elements will enhance the efficiency of your machine, ultimately contributing to a smoother, more productive experience with your outdoor tasks. Know your equipment to keep it in top condition year-round.

Understanding Lawn Equipment Components

When working with outdoor machinery, it’s essential to have a clear understanding of how each element functions and contributes to the overall performance. Recognizing the role of each piece helps ensure efficient operation and maintenance, allowing for easier troubleshooting and repair. Knowing the structure of your equipment also makes identifying wear and tear more straightforward, preventing larger issues from developing.

Key Elements of Lawn Care Machines

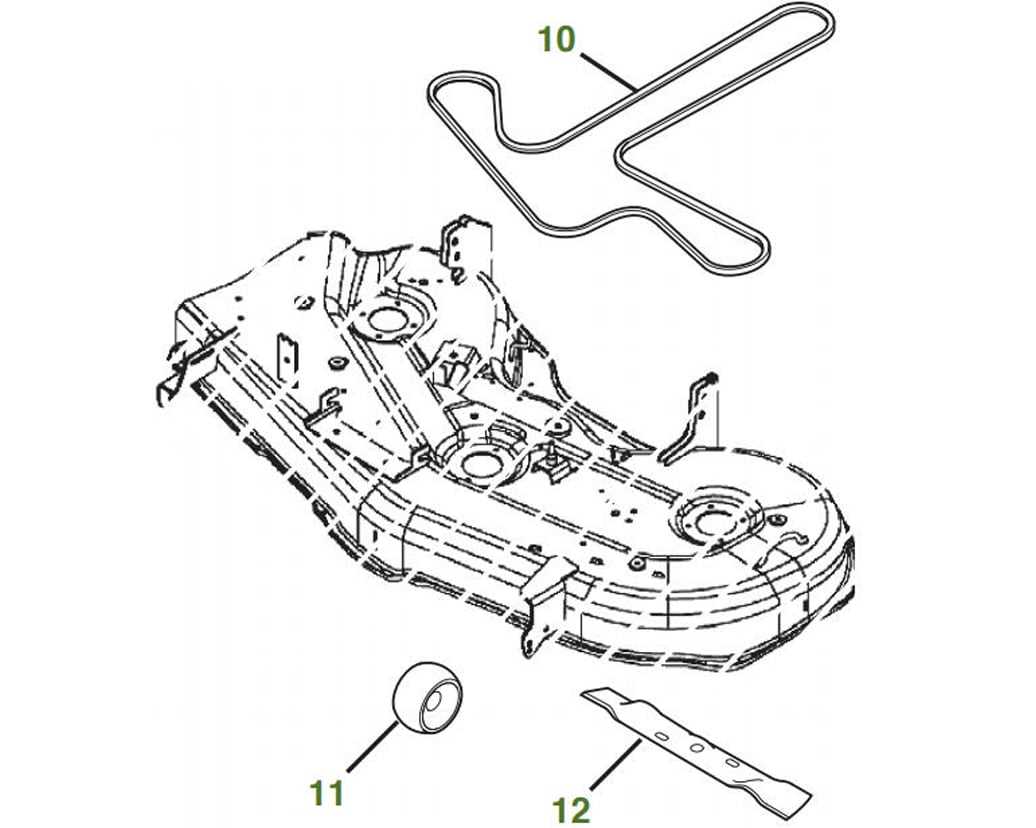

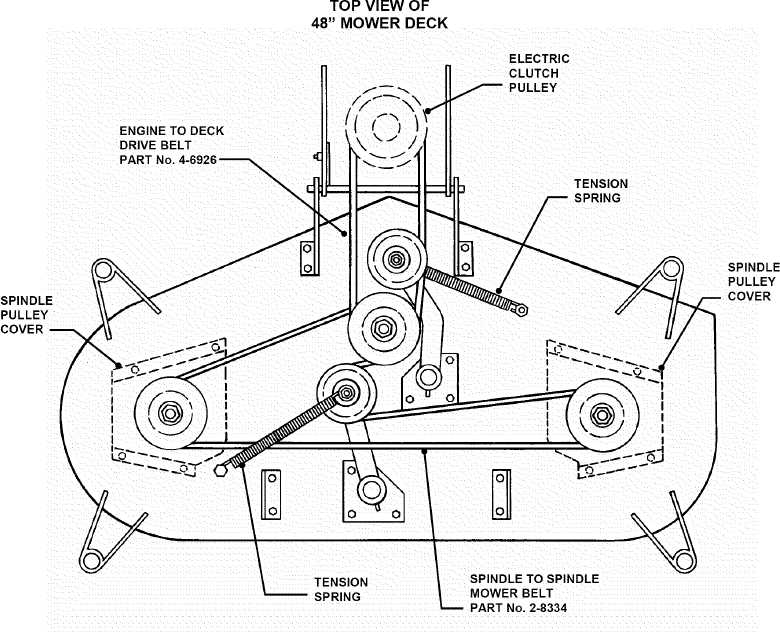

Every device designed for lawn care includes several key components, each serving a unique purpose. From rotating blades to the structure that holds them in place, each part is crucial for delivering the desired results. Understanding the function of each item ensures smooth operation, whether it’s replacing a worn-out piece or conducting regular cleaning and servicing.

Common Issues and Troubleshooting

Even with regular maintenance, certain components may show signs of wear over time. Common issues often stem from damaged or misaligned pieces, which can affect the quality of work and the longevity of the machine. Knowing how to quickly assess these elements allows owners to make timely adjustments and keep their equipment running at peak performance.

How to Identify Deck Components Easily

Proper identification of the elements within your lawn care equipment is vital for effective maintenance and repairs. Recognizing the components accurately can save time, reduce mistakes, and help you quickly source the right replacements. Here are several steps to simplify the process of identifying different parts and ensuring your machine functions smoothly.

- Study the User Manual: Always begin with the user manual for detailed diagrams and explanations of each part. It provides a comprehensive breakdown of the machinery, which can be crucial when trying to identify specific components.

- Visual Inspection: Carefully inspect the machinery for visible labels or markings on the parts. Manufacturers often label parts to help users distinguish between various components.

- Check for Wear and Tear: Look for signs of wear, cracks, or rust that may point to the part’s function and condition. For instance, a worn-out component might reveal its role by the area of stress it exhibits.

Once you familiarize yourself with the general look and feel of the different parts, performing maintenance or repairs becomes a much easier task. Over time, this knowledge will allow you to quickly identify and resolve issues as they arise, ensuring the longevity of your equipment.

Common Issues with Lawn Equipment Components

Over time, certain components of lawn care machinery are prone to wear, leading to issues that can affect performance. Identifying these problems early on can help you avoid costly repairs and ensure the longevity of your equipment. Some of the most common issues with these elements can range from misalignment to general damage caused by regular use.

One frequent issue is the buildup of debris and grass clippings, which can clog or restrict movement, causing parts to work harder and wear out faster. Another common problem is rust, particularly in areas that are exposed to moisture, which can weaken the material and affect its functionality. Misalignment or loosening of certain pieces can also occur, which often results in less efficient operation or even a complete failure of the component.

Addressing these issues early can improve the efficiency and lifespan of your machine, allowing you to perform tasks more effectively while avoiding larger mechanical failures in the future.