When it comes to vehicle maintenance and repairs, knowing the structure and function of key mechanisms is essential. Understanding how different elements interact within a machine can greatly enhance the repair process, helping to identify issues quickly and efficiently. This knowledge allows technicians to address problems with precision and ensure vehicles operate smoothly.

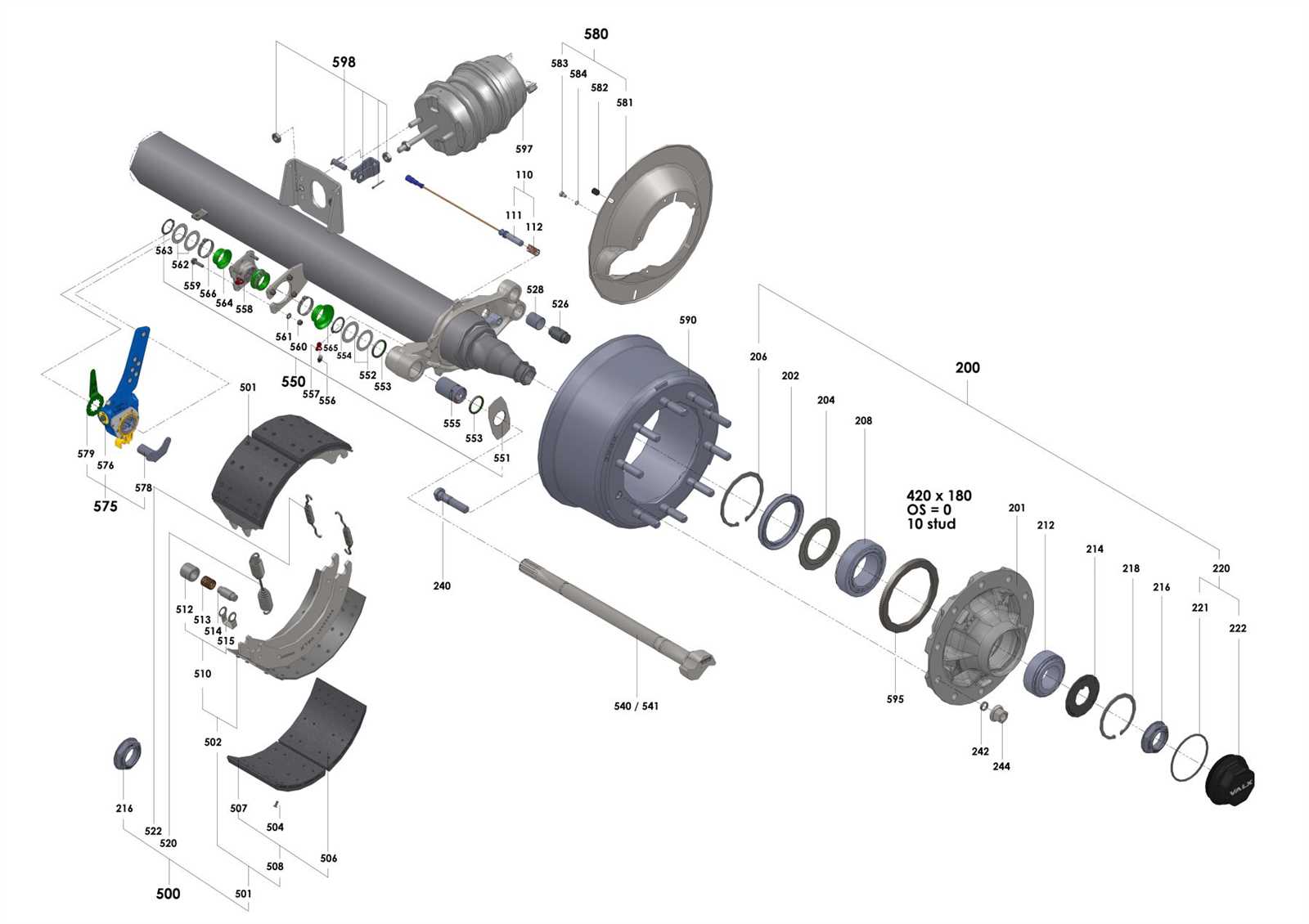

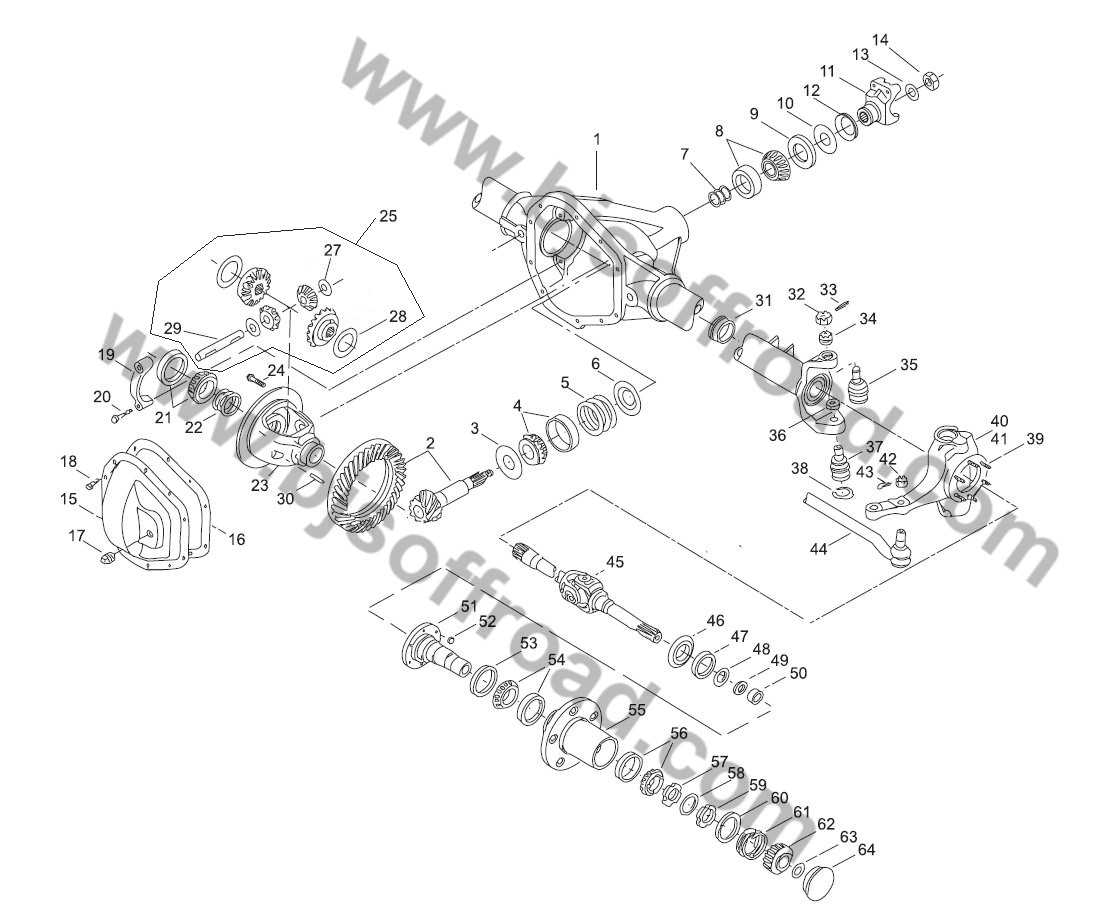

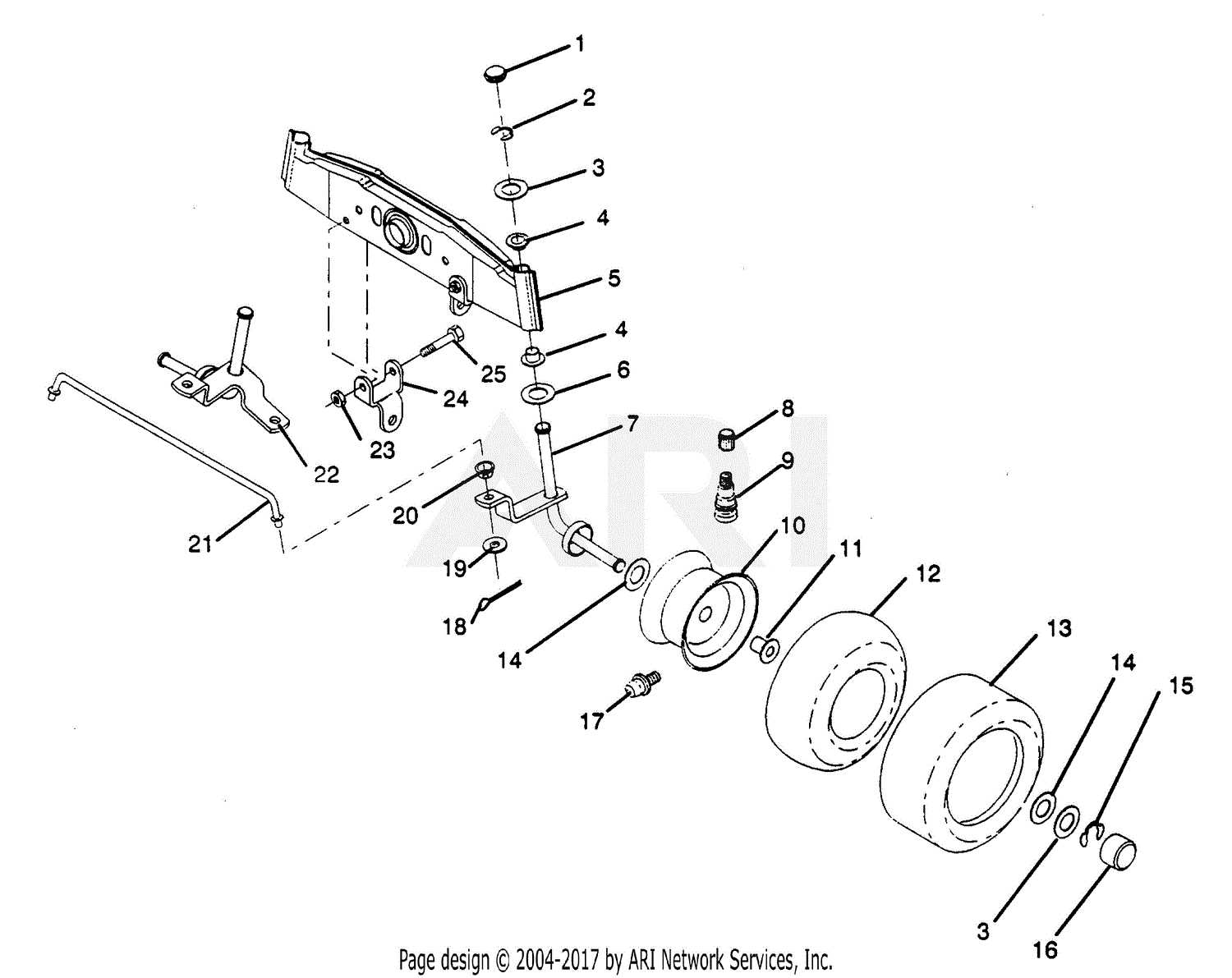

Detailed schematics provide a visual map, showing how each component fits together, their roles, and how they support the overall system. By studying these layouts, one gains insight into the engineering behind complex machinery, making it easier to troubleshoot or upgrade specific features.

For anyone working with vehicle mechanics, familiarity with these visual aids offers a clear path to resolving issues. Understanding how systems work together not only improves repair accuracy but also aids in the installation of new components, ensuring optimal performance of the vehicle.

Overview of Vehicle Components and Functions

The complex structure of a vehicle relies on various interconnected systems that work together to ensure smooth and safe operation. Each system consists of multiple components, each with a specific role that contributes to the overall functionality. By understanding the relationship between these elements, one can better appreciate the engineering behind their design and purpose.

Key mechanisms are responsible for transmitting power from the engine to the wheels, allowing for efficient movement. These systems often include crucial elements that support rotation, provide stability, and absorb shocks during driving. Each element has a distinct function, from those responsible for rotation to those that maintain balance under varying conditions.

Understanding how these components interact is essential for anyone involved in maintenance or repair. Recognizing the role of each piece helps identify potential issues quickly, which is vital for performing repairs or upgrading systems to maintain vehicle performance.

Key Parts in an Assembly

A vehicle’s drive system is composed of several crucial elements that work together to transfer power from the engine to the wheels. These elements must be strong, durable, and precisely engineered to handle the stresses of movement and varying road conditions. The interaction between these key components ensures smooth operation and optimal performance of the vehicle.

Rotation and Power Transmission

The most important components in this assembly are responsible for transmitting power. These include elements designed to facilitate rotation and ensure power is evenly distributed to each wheel. The role of these components is to maintain a constant flow of energy, enabling movement and maneuverability.

Support and Stability

Other critical components provide stability and support. These parts are designed to absorb impacts, reduce vibrations, and maintain the alignment of the system. Their function is vital to ensure that the vehicle remains balanced, offering both safety and comfort during operation.

How Visual Schematics Assist in Vehicle Repairs

When it comes to vehicle maintenance, a clear understanding of the internal systems is essential for diagnosing and fixing issues. Visual schematics serve as a valuable tool, helping technicians quickly identify the location and function of different components within a complex assembly. These diagrams make it easier to understand how each element interacts with others, leading to more accurate repairs and efficient troubleshooting.

Improved Diagnostics

Visual representations allow technicians to identify problems more efficiently by providing a clear view of the system layout. With these schematics, it’s easier to locate faults in specific areas, whether due to wear, misalignment, or damage. This focused approach speeds up the repair process and ensures that the right components are addressed.

Efficient Component Replacement

Once a problem is identified, visual guides help determine the proper steps for replacing or repairing components. These guides show how parts are connected, the tools needed, and the correct order of operations, which reduces the risk of errors during the repair process. By following a step-by-step approach, technicians can maintain vehicle performance and longevity.