When dealing with any coffee maker, it is essential to be familiar with its individual components to ensure efficient operation and maintenance. A comprehensive guide to these internal elements can significantly aid in troubleshooting, repairs, and upgrades. With a solid understanding of how each piece fits together, you’ll be able to extend the lifespan of your machine and improve its performance.

Maintenance and repair often require a clear overview of the essential mechanisms inside your device. Identifying each part’s function allows you to diagnose common issues, replace worn-out elements, and enhance overall functionality. This knowledge is invaluable, especially when trying to solve a malfunction or carry out preventative measures.

Whether you are a seasoned user or a first-time owner, having easy access to a detailed reference guide of your machine’s structure ensures that you can confidently address any concerns. This resource will walk you through the key components, helping you better understand their roles and how they contribute to the machine’s overall performance.

Understanding Philips 3200 Parts Layout

Knowing the internal structure of your coffee machine is essential for smooth operation and proper maintenance. Each component plays a unique role in ensuring the machine functions at its best. By familiarizing yourself with these parts, you can quickly identify any issues and determine the necessary steps for repair or replacement.

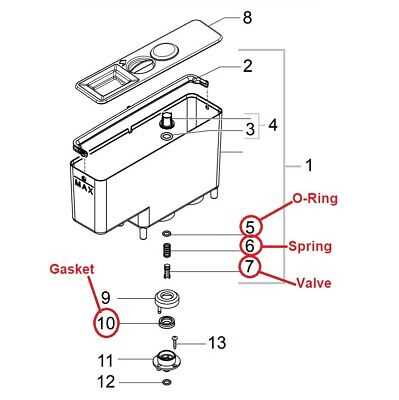

The layout of the machine includes various elements that work together to brew a perfect cup. These parts include mechanisms for water flow, brewing pressure, and temperature regulation. Understanding how each part interacts within the system makes it easier to troubleshoot common problems such as low pressure or malfunctioning components.

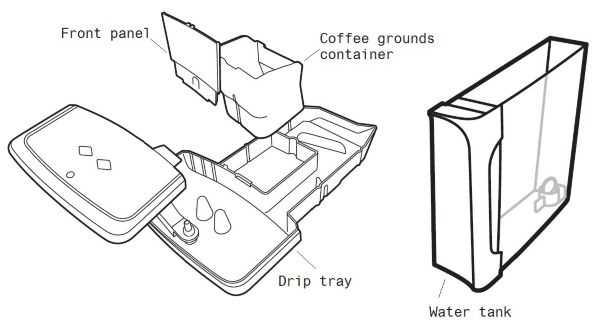

Being aware of the arrangement and function of these elements also allows you to perform regular maintenance tasks more efficiently. For example, knowing where the water tank, filter, and grinder are located can help you clean and replace them as needed, preventing buildup and ensuring long-term performance.

How to Use the Philips 3200 Diagram

Understanding how to reference a machine’s internal layout can be an invaluable tool for both repair and maintenance. By using a well-organized visual representation of the device’s structure, you can quickly locate components and troubleshoot effectively. This method allows users to identify each element, understand its function, and proceed with necessary fixes or replacements.

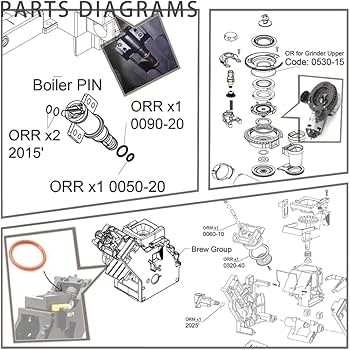

To get the most out of the schematic, start by identifying the main systems that require attention. Whether you’re dealing with issues related to water flow, grinding, or brewing pressure, locating these specific areas on the diagram can speed up your diagnosis. It provides a clear view of how parts connect and interact, which is essential for accurate repairs.

Additionally, the diagram serves as a useful reference when performing routine maintenance. Knowing where key components are located helps with tasks such as cleaning, lubricating, or replacing worn-out parts. Following the layout step-by-step ensures that you don’t miss any critical areas that could affect the machine’s performance over time.

Common Issues and Part Identification

Understanding the common issues that can arise with your coffee machine is crucial for timely troubleshooting and repair. Many problems stem from specific components that wear out or malfunction over time. Identifying these parts quickly allows for efficient solutions, saving both time and money on unnecessary repairs.

Water flow issues are among the most common complaints, often caused by blockages or damaged pumps. Recognizing the symptoms and knowing where to locate the water circulation components is the first step in addressing the problem. In some cases, mineral buildup can restrict water flow, requiring cleaning or part replacement.

Grinding problems may also occur when the grinder or related mechanisms malfunction. If the machine fails to grind beans properly or produces inconsistent results, it is likely due to wear or clogging in the grinding system. Identifying the grinder and its related parts helps narrow down the cause, making it easier to resolve.

Other common issues include poor brewing pressure or temperature control, which are often linked to defective valves or thermostats. Understanding how each piece functions and its role within the larger system allows for quicker and more accurate repairs.