Every cleaning device consists of various essential elements that work together to deliver efficient performance. A thorough understanding of these components is crucial for both usage and maintenance. By examining how each piece contributes to the overall function, users can ensure better care and longevity of their equipment.

When exploring the inner workings of these tools, it is important to recognize how each individual piece interacts with the others. From the trigger to the hose connections, every part plays a role in delivering the desired results. Knowing the names, functions, and maintenance procedures of these components allows for smoother operation and quicker troubleshooting.

Maintenance is key to preserving the effectiveness of your cleaning device. Regular checks and proper care of each part can prevent many common issues and extend the lifespan of your equipment. A clear understanding of the inner mechanics can also help identify potential problems early, saving both time and money on repairs.

Understanding Pressure Washer Gun Components

To ensure the optimal performance of any cleaning tool, it is essential to understand how the various elements within the system interact with each other. Each component plays a specific role in delivering powerful cleaning action, from the initial trigger mechanism to the final nozzle. Familiarizing yourself with these components will help you maintain and troubleshoot the equipment more efficiently.

Main Mechanisms Involved

At the heart of the device, the trigger mechanism controls the flow of water or cleaning solution. This simple yet crucial part is designed to allow the user to start or stop the cleaning process with ease. Nearby, the control valves regulate the pressure levels, ensuring that the force applied is appropriate for different surfaces and cleaning tasks. These elements must work in harmony to achieve consistent performance.

Supporting Elements and Their Roles

Additional components, such as the handles and connectors, provide ergonomic support and facilitate easy handling. The hose connects the device to the water source, while specialized nozzles direct the flow precisely to the targeted area. Each of these supporting parts has a direct impact on usability, and understanding their specific functions ensures a smoother and more efficient cleaning experience.

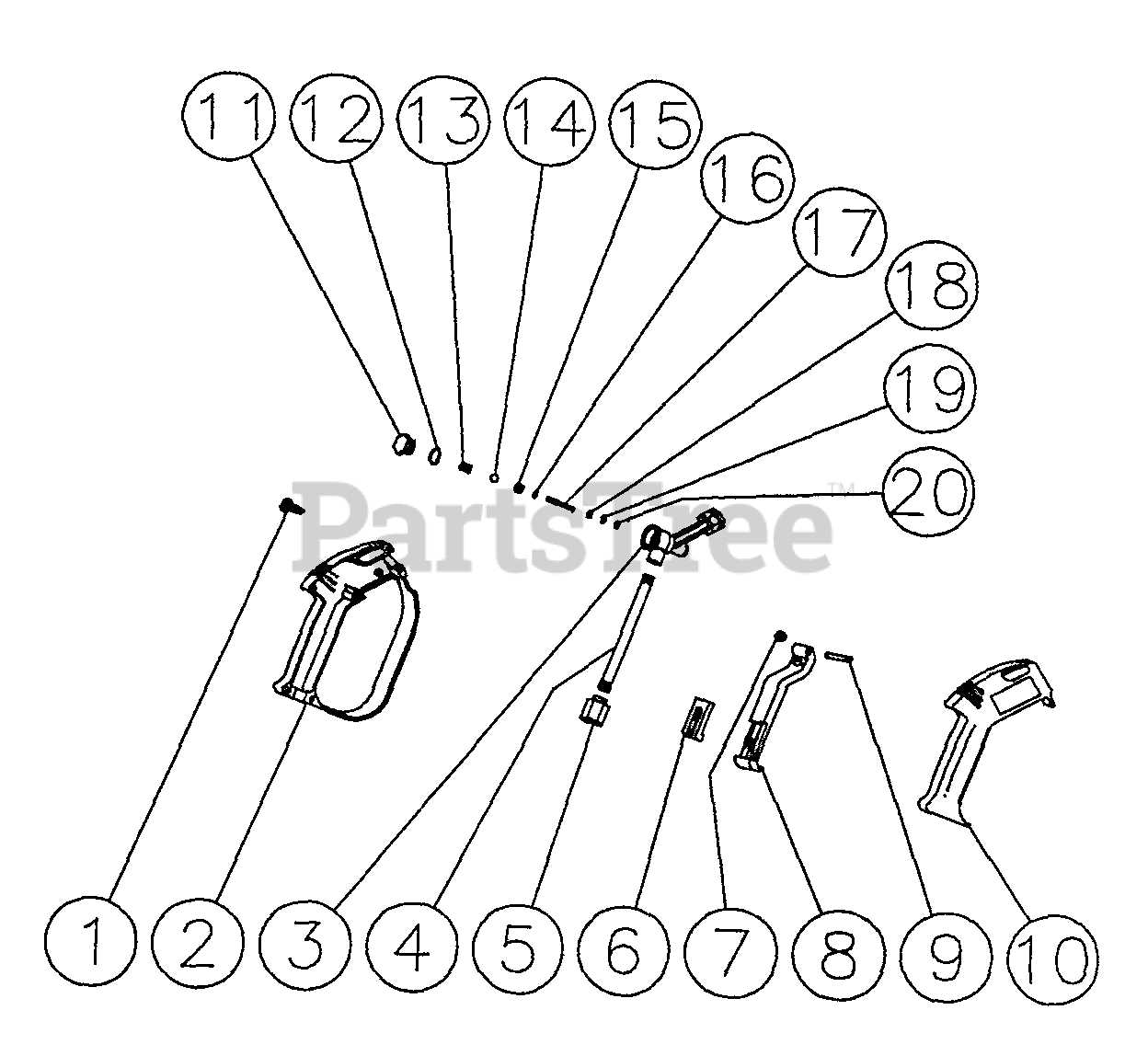

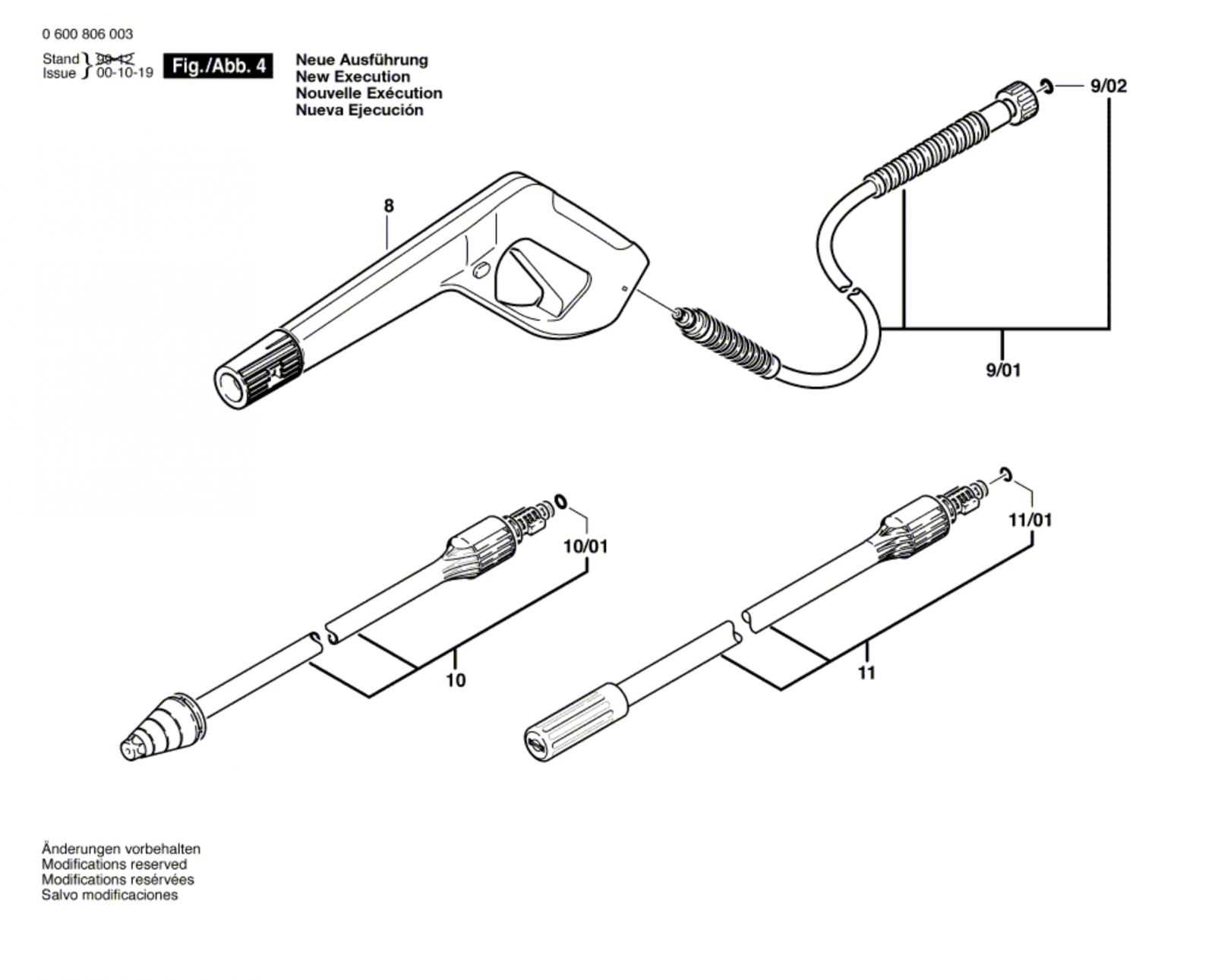

How to Identify Each Part in the Diagram

Understanding the different components of a cleaning device requires familiarity with the visual layout of its structure. A detailed illustration can help users recognize the specific elements and their respective locations. By carefully studying the image, you can identify how each section contributes to the overall functionality of the tool.

The first step in identifying the components is to look for the most prominent parts, such as the trigger mechanism and the pressure control areas. These are usually highlighted due to their importance in regulating operation. Next, look for the connectors and handles, which are essential for ease of use. They often appear near the central structure, providing both comfort and control during the cleaning process.

Finally, pay attention to smaller components like nozzles, valves, and hoses. These elements are typically placed towards the outer edges of the diagram but are just as critical for the device’s overall performance. Recognizing the placement and function of each part will allow you to better understand how the entire system operates and ensure proper maintenance.

Tips for Maintaining Pressure Washer Gun Parts

Proper maintenance is essential to ensure the longevity and efficiency of your cleaning equipment. Regular upkeep helps prevent breakdowns and keeps the tool operating at peak performance. With a few simple steps, you can maintain all the critical components and extend their useful life.

Start by inspecting the most vulnerable parts, such as the nozzles and valves, which are subject to wear and tear. Clean them after every use to prevent clogs and buildup that can reduce the device’s effectiveness. It’s also important to check the trigger mechanism regularly for any signs of stiffness or malfunction. Lubricating moving parts can help maintain smooth operation and prevent unnecessary strain on the system.

Don’t forget to examine the connectors and hoses for any signs of cracks or leaks. These areas can be prone to damage, especially when the equipment is stored improperly. Ensure that all connections are secure before each use to avoid water pressure loss. Proper storage, away from extreme temperatures, also plays a significant role in preserving the integrity of your device’s components.