When it comes to maintaining and repairing your boat’s propulsion system, having a clear understanding of its individual components is essential. Knowing how each part fits together and operates can greatly improve your ability to troubleshoot and make necessary repairs. This section will guide you through the key elements of the motor and provide insights into how to manage them effectively.

Proper maintenance is crucial for ensuring that your boat’s motor continues to perform at its best. By familiarizing yourself with the different elements, you can prevent unnecessary wear and tear. Additionally, understanding how to identify common issues will help you catch problems early, saving both time and money.

Whether you’re looking to replace a worn-out part or simply want to enhance the performance of your equipment, this guide will equip you with the knowledge you need to take the right steps. Let’s dive into the most important aspects of your motor and how to interpret its assembly effectively.

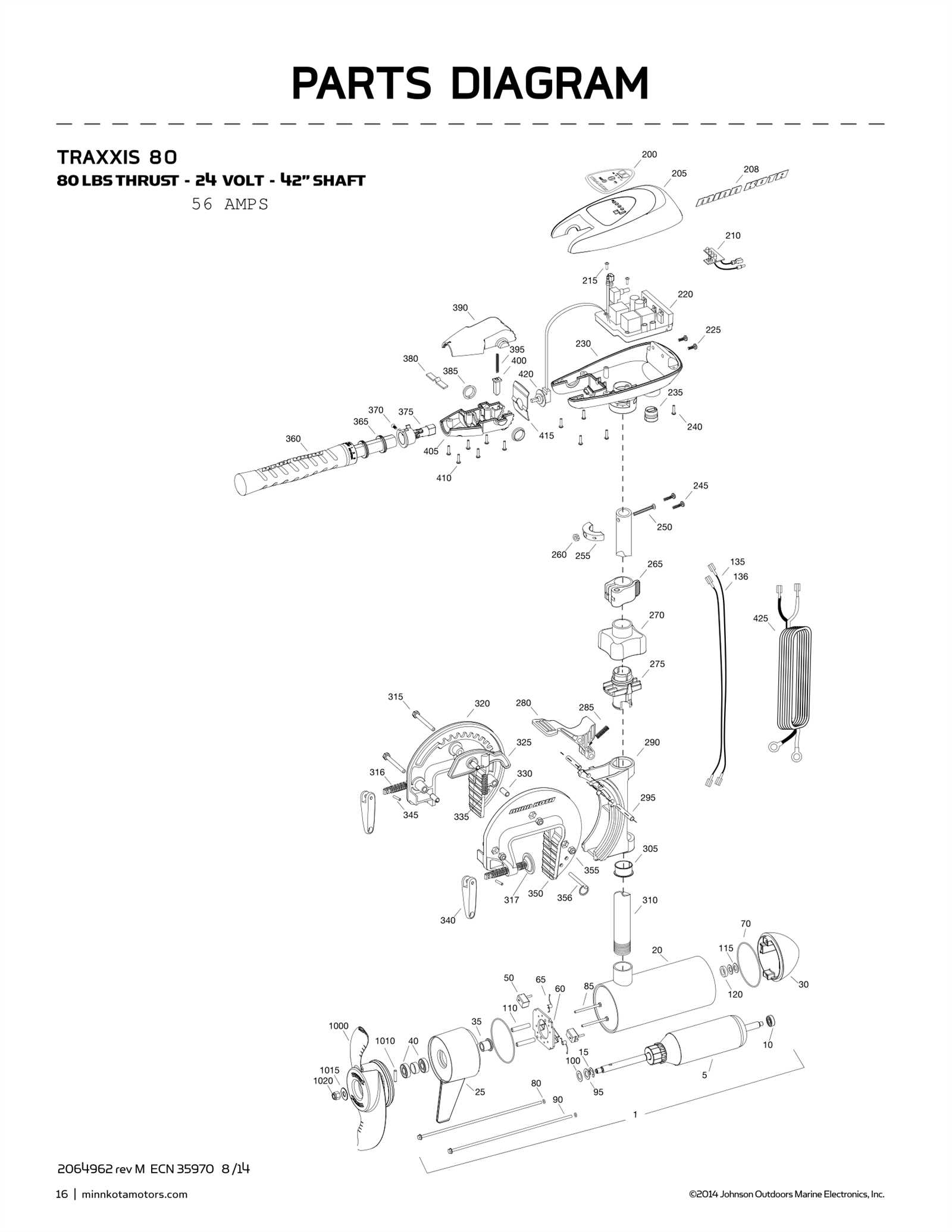

Minn Kota Terrova 80 Parts Overview

Understanding the components of your boat’s motor is essential for proper maintenance and smooth operation. Every element plays a role in ensuring that the system functions efficiently, from the propeller to the power source. Familiarizing yourself with the various sections and their purpose can make the difference between timely repairs and costly mistakes.

In this section, we will explore the essential components of the motor system, highlighting the key elements you should know. These include the drive unit, the electrical system, and the steering mechanisms, among others. By having a clear picture of how these parts interact, you can better manage repairs or replacements when necessary.

Knowing which parts are crucial for performance and longevity allows you to focus on areas that may need attention. Whether you’re dealing with wear and tear or trying to enhance overall efficiency, a thorough understanding of the equipment will lead to more informed decisions and better upkeep.

How to Read the Terrova 80 Diagram

Interpreting technical illustrations is crucial for understanding the design and functionality of your boat’s motor system. These visual guides provide a detailed breakdown of each component and its relation to the overall assembly. Knowing how to read these diagrams allows you to make informed decisions during repairs or upgrades.

Identifying Key Components

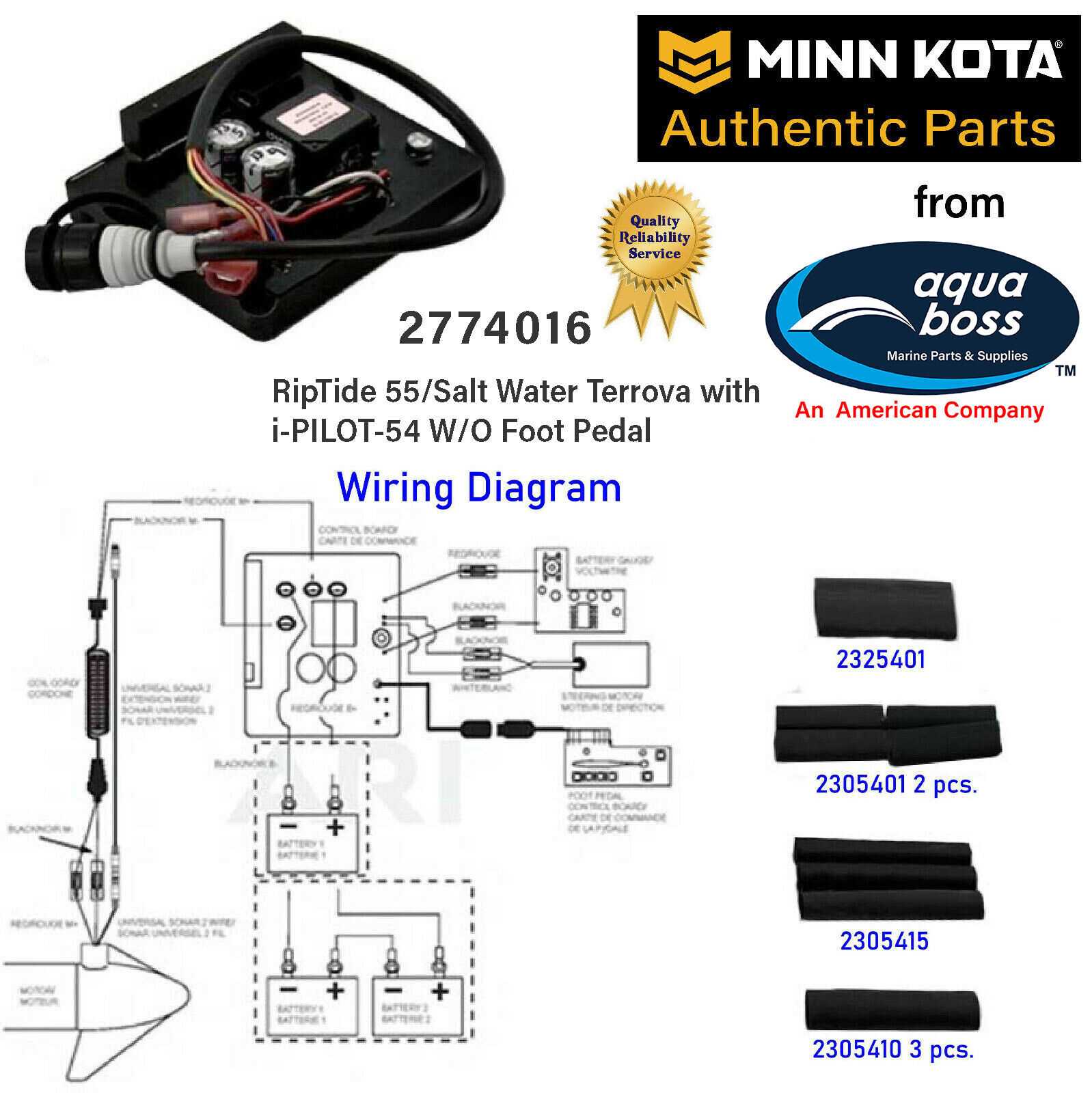

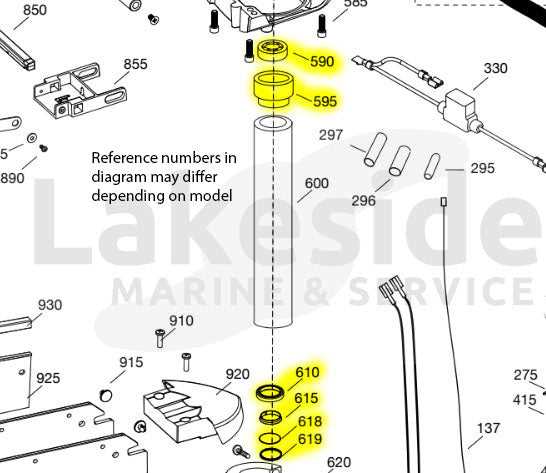

The first step in reading the diagram is recognizing the most important parts of the system. Look for labeled sections that indicate the motor’s primary elements, such as the propulsion unit, control system, and power connections. These labels help you pinpoint the components you may need to address for maintenance or replacement.

Understanding Component Connections

Once you’ve identified the main parts, focus on how they are connected to one another. Arrows, lines, or other symbols will indicate how each component interacts with others, allowing you to see the flow of energy or movement throughout the system. This understanding is vital when troubleshooting any operational issues or ensuring everything is properly aligned during reassembly.

Common Issues with Terrova 80 Parts

While maintaining your boat’s motor system, it’s essential to be aware of the common issues that can arise with its components. These problems often stem from wear and tear, improper use, or environmental factors. Recognizing these issues early can prevent major breakdowns and costly repairs.

Electrical System Failures

One of the most frequent issues is related to the electrical connections. Loose or corroded terminals, faulty wiring, or weak battery connections can cause the motor to malfunction or lose power. Regular inspection of the wiring and connectors can help you spot these issues before they lead to bigger problems.

Propeller and Drive Shaft Wear

The propulsion system, including the propeller and drive shaft, is another area prone to damage. Rocks, debris, and regular use can cause the blades to chip or crack, affecting performance. Replacing worn-out components and ensuring that the shaft is properly lubricated can extend the life of these crucial parts.