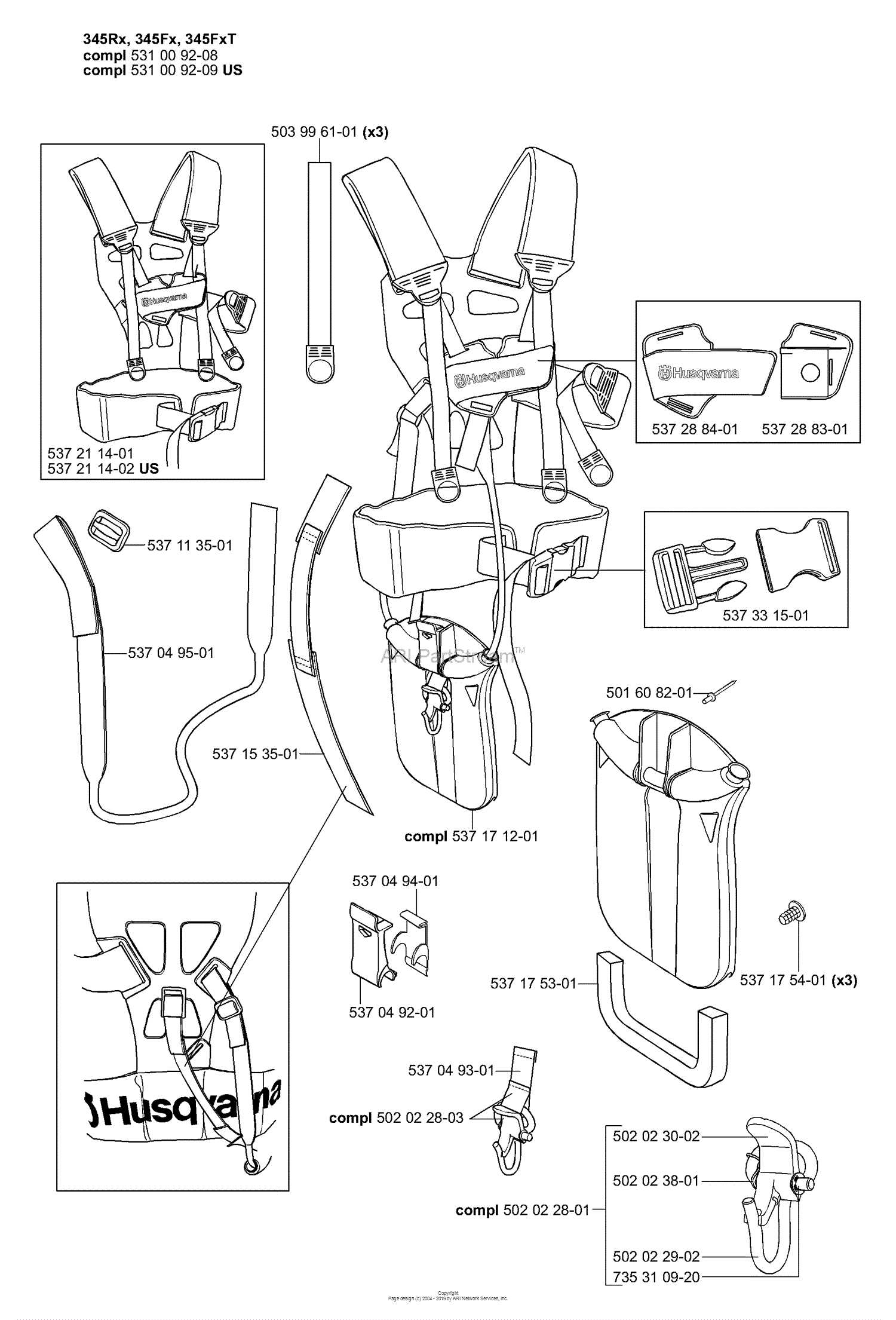

When it comes to ensuring the longevity and performance of your chainsaw, having a clear understanding of its internal structure and individual elements is crucial. Each component plays a vital role in its overall function, making it essential to know how they fit together and how they can be maintained over time.

By breaking down the assembly into distinct sections, you can better assess which parts need regular attention or replacement. Whether you’re performing basic upkeep or tackling a repair, knowing the key components and their arrangement can help prevent mishaps and ensure smooth operation for extended periods.

Proper maintenance is key to extending the life of any tool, especially a high-performance machine. With the right knowledge, you can easily identify issues, order the correct replacements, and perform efficient repairs yourself, avoiding unnecessary costs or delays.

Understanding the Chainsaw Components

A chainsaw is a complex machine made up of various elements that work together to provide powerful cutting capabilities. Each component is specifically designed to contribute to the overall functionality and durability of the tool. To ensure optimal performance, it’s important to understand how each part interacts with the others and the role it plays in maintaining the chainsaw’s efficiency.

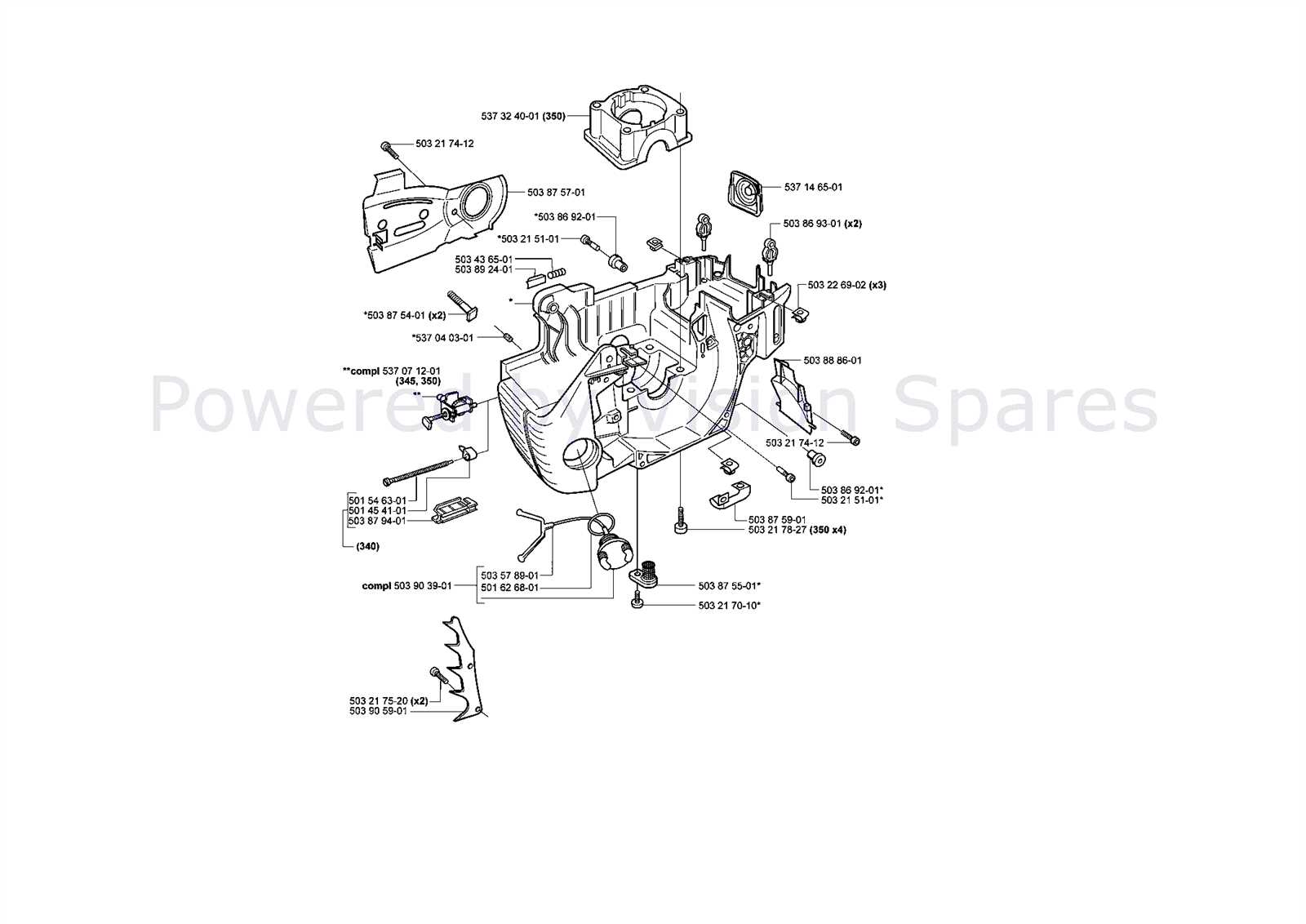

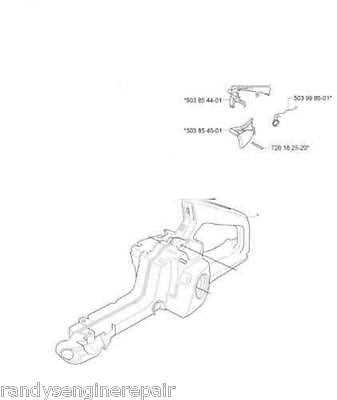

Main Structural Elements

The frame of the chainsaw houses all internal components and provides support for the entire assembly. The engine is the heart of the machine, converting fuel into mechanical energy to power the chain. Alongside the engine, the clutch, sprocket, and bar are essential for transferring energy and controlling the movement of the cutting tool.

Key Moving Components

The most critical moving parts include the chain, which is responsible for cutting through material, and the tensioner, which ensures the chain remains tight and operational. The oil system is also crucial, lubricating the chain for smoother operation and reducing wear. Understanding these moving elements can help in troubleshooting performance issues and ensuring the chainsaw runs efficiently over time.

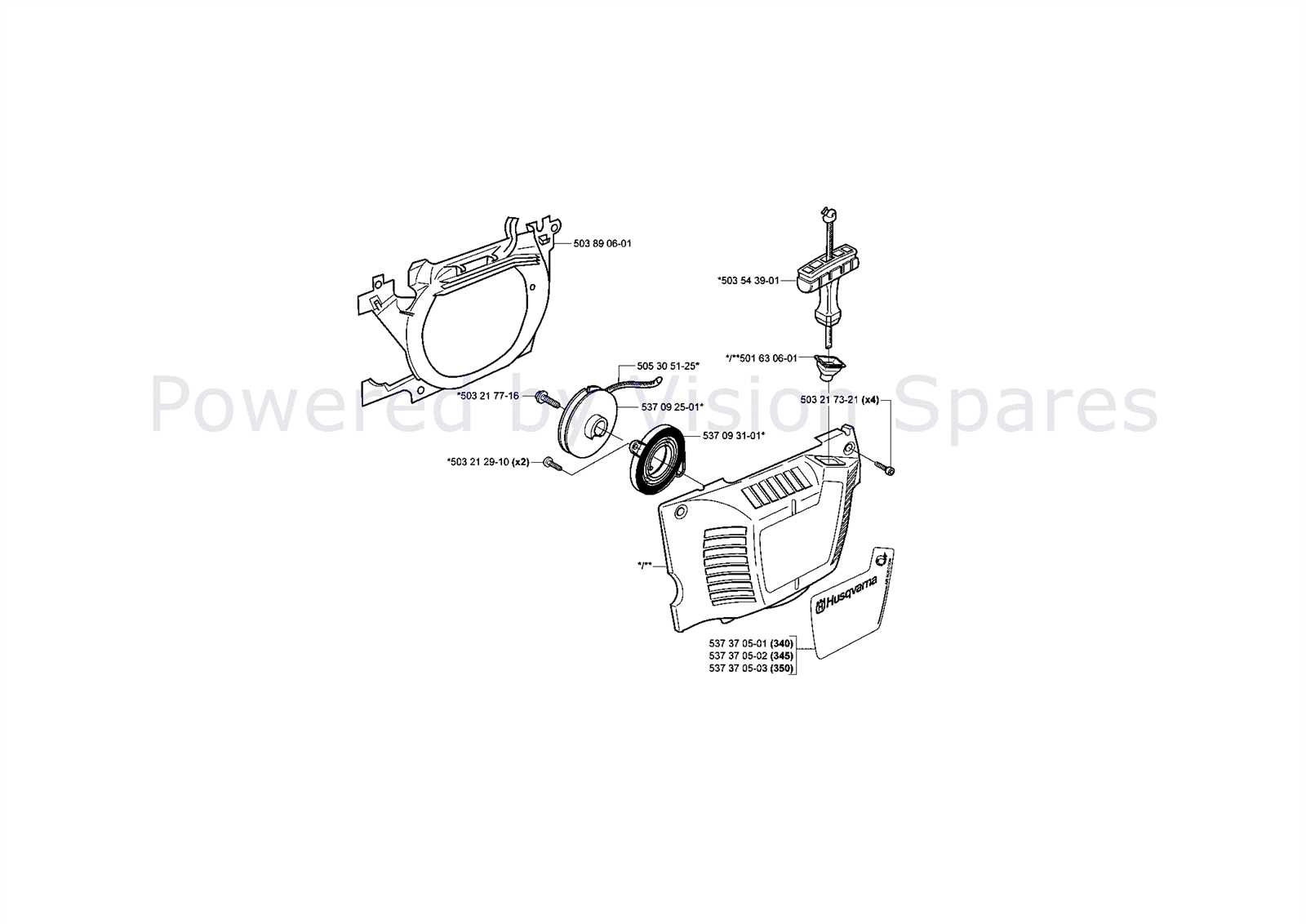

Detailed Breakdown of Chainsaw Components

Understanding the individual elements of a chainsaw helps ensure that it operates smoothly and efficiently. Each component contributes to the overall performance, and recognizing the function of each allows for proper maintenance and timely repairs. In this section, we’ll explore the key components that make up the tool, their roles, and how they work together to keep the machine running at its best.

Essential Engine and Drive Mechanisms

The engine is the central driving force of the chainsaw, converting fuel into power. Along with the carburetor and spark plug, these parts form the ignition and combustion system that keeps the chainsaw running. The clutch, sprocket, and chain bar are part of the drive system, transferring the energy from the engine to the cutting chain. These elements work in unison to ensure the chain operates efficiently without interruptions.

Support and Lubrication Systems

The frame of the chainsaw provides support for all internal parts, keeping them securely in place. The oiling system plays a critical role by ensuring that the chain is constantly lubricated, reducing friction and extending the life of both the chain and the engine. Additionally, the air filter and fuel system help maintain the correct balance of air and fuel, preventing the engine from overheating and ensuring smooth operation.

Essential Maintenance Tips for Chainsaw

Proper upkeep is vital to ensuring the longevity and reliability of any chainsaw. Regular maintenance not only improves performance but also helps prevent costly repairs and replacements. By following a few simple steps, you can keep the tool running smoothly and efficiently for years to come.

Regular cleaning is one of the most effective ways to maintain a chainsaw. Removing dirt, sawdust, and debris from the body, chain, and air filter ensures that the machine operates without obstruction. It’s also important to inspect the chain tension frequently. If the chain becomes too loose, it can cause inefficiency and even damage to the machine, so adjusting the tension as needed is crucial.

Oil maintenance is another essential task. Ensure that the oil tank is always full and that the chain is adequately lubricated during use. Neglecting this aspect can lead to excessive wear on the chain and bar, reducing their lifespan. Finally, sharpening the chain regularly helps maintain its cutting efficiency, reducing strain on the engine and providing smoother operation.