Efficient irrigation systems rely on a variety of components working together seamlessly. Identifying and understanding these elements is crucial for proper maintenance and repair. With the right knowledge, any user can troubleshoot, replace, or upgrade specific parts to ensure optimal performance over time.

In this section, we will explore the essential elements of these systems, providing a comprehensive overview of each key component. From valves and connections to moving parts, knowing how they function and interact will help you avoid costly repairs and extend the lifespan of your equipment.

Whether you’re a seasoned professional or a beginner, mastering the layout of these systems is a valuable skill. This guide will provide you with the tools to assess the condition of your equipment and understand its inner workings more effectively.

Understanding the Irrigation System

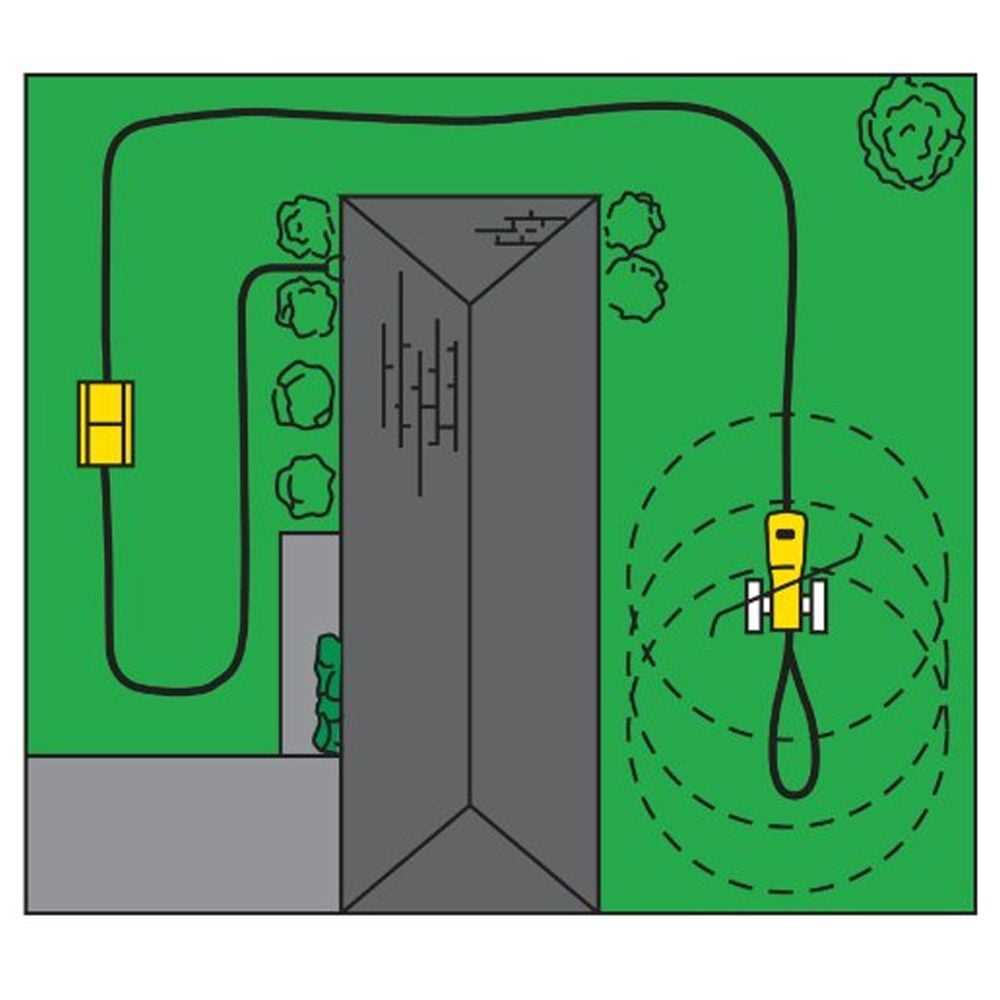

An efficient irrigation setup consists of various elements working in unison to deliver water effectively across large areas. The functionality of these systems is based on the interaction between moving and stationary components that are designed to ensure water is distributed evenly and accurately. Understanding each of these elements is vital for maintaining optimal operation and troubleshooting potential issues.

At the core of these systems, there are mechanical and hydraulic components that allow for precise water flow control. Knowing how these elements work together helps in diagnosing problems, whether they involve inconsistent coverage, blockages, or mechanical failure. Each segment plays a specific role, from the driving mechanism to the distribution parts, ensuring a balanced flow of water throughout the field or garden.

Regular maintenance and familiarity with the system’s design can prevent major malfunctions and extend the lifespan of the equipment. The key is understanding the layout and operation of each functional part, allowing for quick identification of faults and efficient repairs when necessary.

How to Identify Key Irrigation System Components

Properly identifying the main elements of an irrigation system is crucial for effective maintenance and troubleshooting. Understanding each component’s role and how it fits into the overall system ensures you can pinpoint issues quickly and carry out repairs or replacements efficiently. Each piece plays a specific function that contributes to the successful operation of the entire setup.

Recognizing the Primary Elements

The most important elements in these systems are usually the driving mechanism, distribution nozzles, and control valves. The driving mechanism powers the system’s movement, while the distribution nozzles are responsible for evenly dispersing water across the area. Control valves regulate water flow, ensuring the system operates smoothly and according to specific needs. Identifying these components is the first step in diagnosing any issues and replacing worn-out or damaged parts.

Assessing Condition and Functionality

Once the main components are identified, evaluating their condition is key. Look for signs of wear, corrosion, or any physical damage that could affect performance. For instance, a malfunctioning control valve might cause uneven watering, while a worn-out nozzle can result in water inefficiency. Regular inspections help spot problems early, preventing larger failures that could disrupt the entire irrigation process.

Step-by-Step Guide to Replacing Components

Replacing faulty components in an irrigation system is essential to maintain its efficiency and extend its lifespan. This process involves identifying the broken or worn-out parts, removing them carefully, and installing new ones with precision. By following a clear, systematic approach, you can ensure the system operates at its full potential and avoid further complications down the line.

Step 1: Turn Off the System

Before starting any repairs, always ensure the system is completely turned off. Disconnect any power sources and shut off the water supply to prevent leaks or electrical hazards while working on the equipment.

Step 2: Identify the Faulty Component

Examine each part of the system closely to locate the damaged or malfunctioning component. This may involve checking for leaks, blockages, or signs of wear. If you’re unsure, refer to the system’s manual to help identify specific components and their functions.

Step 3: Remove the Old Component

Carefully remove the damaged part. Depending on the design, this could involve unscrewing bolts, detaching connections, or gently prying off the part. Be cautious not to damage surrounding components during this process.

Step 4: Install the New Component

Once the old part is removed, place the new component in the same position. Ensure it fits securely and is aligned correctly. Tighten all connections and fasten the part according to the manufacturer’s instructions.

Step 5: Test the System

After replacing the faulty component, turn the system back on and check for proper functionality. Look for even water distribution, proper movement, and any signs of leaks or malfunctions. If everything works smoothly, you’ve successfully completed the replacement.