Knowing the key elements of a cleaning machine and how they function is essential for maintaining optimal performance. A clear understanding of these components allows for better troubleshooting and efficient repairs when needed. Identifying and replacing worn-out or broken pieces can significantly extend the lifespan of your device.

By recognizing the different sections of the equipment, users can avoid unnecessary breakdowns and enhance the machine’s efficiency. Proper guidance in understanding each part helps ensure that the right steps are taken when it’s time for maintenance or replacement.

Repairing a vacuum cleaner can be straightforward if you have access to reliable information and the correct tools. With the right approach, managing and fixing issues with the unit becomes easier, saving time and money on professional repairs. A systematic guide provides the confidence needed for DIY maintenance.

Understanding Vacuum Cleaner Components

Every cleaning machine consists of various essential components that work together to ensure proper functionality. Each part plays a specific role in maintaining the performance of the unit. By becoming familiar with the different sections of the device, users can better understand how it operates and how to keep it in good condition.

The key elements of the equipment include motors, filters, hoses, and containers, each contributing to the overall efficiency of the machine. Recognizing the purpose of each component is crucial for both troubleshooting and routine maintenance. This knowledge helps to avoid unnecessary repairs and ensures smooth operation for a longer period.

Understanding the setup allows users to quickly pinpoint issues, identify worn-out pieces, and replace them when necessary. Whether it’s for regular upkeep or addressing specific failures, knowing the components and their functions simplifies the maintenance process.

How to Read a Vacuum Cleaner Parts Guide

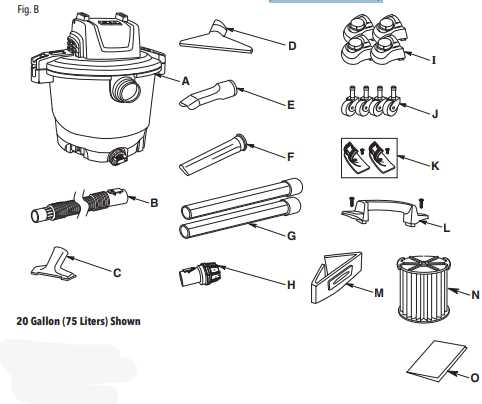

Understanding how to interpret a visual guide of a cleaning machine’s components is an important skill for maintaining and repairing the unit. These illustrations provide a detailed representation of each section, helping users to locate and identify parts that may require attention. By following the guide, you can easily find the necessary replacements or repairs.

Locating Components and Identifying Functions

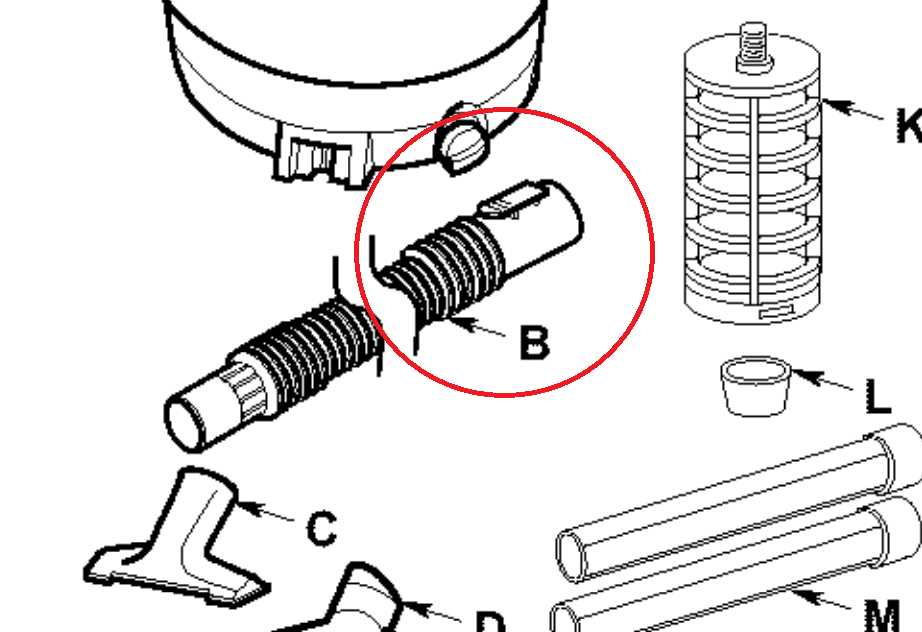

The first step is to understand the layout presented in the guide. Each component is labeled with a reference number or name that corresponds to specific parts. The diagram typically displays all sections in a logical sequence, making it easier to locate each part’s position within the machine. Pay attention to these references, as they will help you match the components with the correct names.

Using the Guide for Repairs and Maintenance

Once the components are identified, you can use the guide to assist with both maintenance and troubleshooting. It will show how each part fits into the overall assembly, which is crucial for reassembly after repairs. By referring to the guide during disassembly or part replacement, you ensure that each component is properly aligned and functioning as expected.

Common Issues and Parts Replacement Tips

Cleaning equipment may face common malfunctions over time, requiring specific components to be replaced. Identifying these issues early on can prevent further damage and extend the life of your machine. Knowing which parts are most likely to wear out helps you prepare for maintenance and repairs more efficiently.

Identifying Wear and Tear

One of the most common problems involves the filter or hose becoming clogged or damaged. Blockages often reduce suction power and lead to overheating. Regularly checking these components can prevent performance issues. If a filter becomes overly dirty or a hose shows signs of wear, it’s time for a replacement. Referencing the machine’s guide will help identify the exact replacement part needed for proper functioning.

Replacing Components and Ensuring Proper Function

When replacing any damaged component, ensure the new part is compatible with your machine. Improper installation of replacement pieces can result in further issues. Always follow the guide carefully when reassembling the equipment after replacing parts, making sure each section is securely fastened. Regular maintenance checks can also help identify parts that need attention before they cause significant damage.