When it comes to operating heavy machinery, understanding the structure and key components is crucial for maintenance and repair. Proper knowledge of how various elements are connected ensures smooth functionality and longevity of the equipment. In this section, we will explore the vital elements of a well-built machine and provide guidance on how to identify and manage them effectively.

The layout of an agricultural vehicle involves several integral parts that work in unison to perform essential tasks. From the engine to the hydraulic system, each component plays a role in ensuring that the machine runs optimally under demanding conditions. It is important to understand how these parts interact and how they contribute to the overall performance.

Having access to detailed information about the specific structure of machinery helps both owners and mechanics. By familiarizing yourself with the layout and arrangement of these key elements, you can enhance your ability to troubleshoot issues and ensure that everything is functioning as it should. This knowledge is not only valuable for repairs but also for optimizing usage and preventing future breakdowns.

Essential Machine Components Overview

Understanding the basic structure of agricultural machinery is key to ensuring its proper operation and longevity. Every system, from the engine to the transmission, is composed of numerous elements that must work together seamlessly. A clear overview of these components allows operators to make informed decisions about maintenance, repair, and performance optimization.

Key Systems and Functions

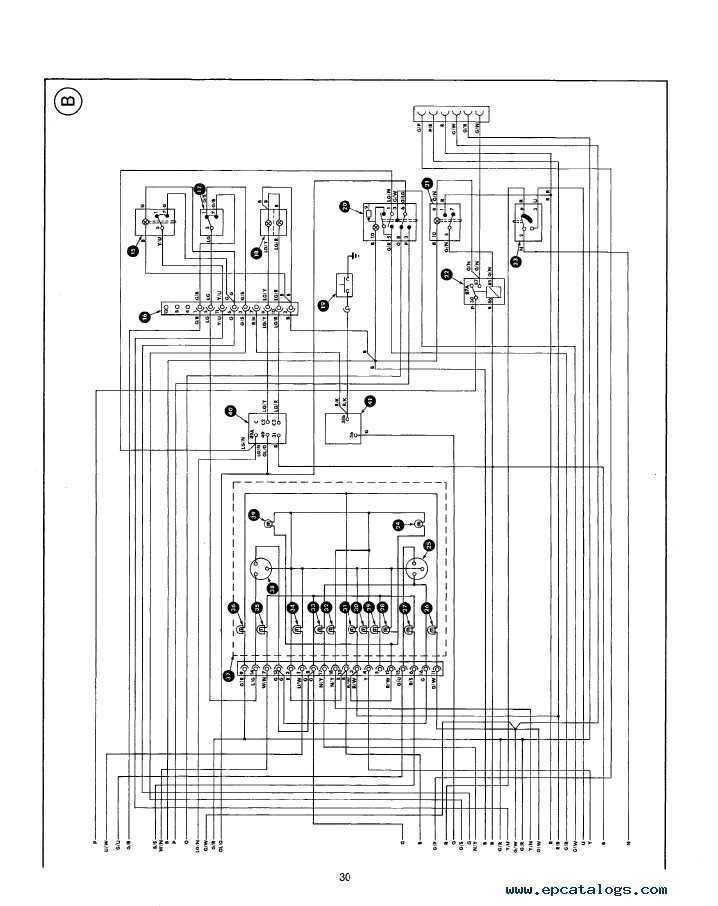

Each machine includes several core systems such as the powertrain, fuel system, and electrical components. These systems work in tandem to provide the necessary functionality for various tasks. The powertrain, for example, connects the engine to the wheels, transmitting power and enabling movement. Meanwhile, the fuel system ensures proper engine performance by regulating fuel intake and combustion processes.

Maintenance and Inspection Tips

Regular inspection and maintenance are essential to keep all systems in peak condition. Routine checks on the engine, hydraulic systems, and drive components can prevent unexpected breakdowns and costly repairs. Proper lubrication and tightening of connections also contribute significantly to the machine’s reliability and efficiency over time.

Identifying Key Components of the Agricultural Machine

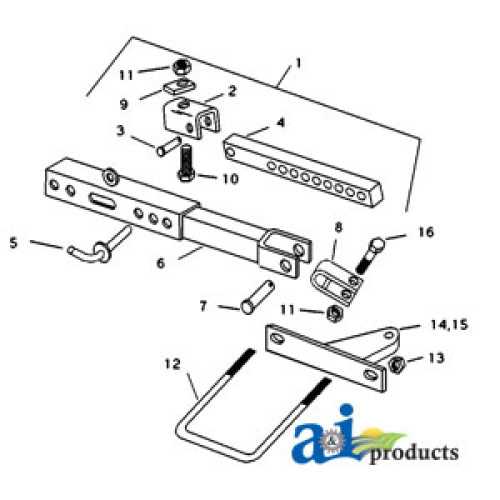

Recognizing the essential elements of a farming vehicle is crucial for both operation and maintenance. Each key component plays a specific role in ensuring that the vehicle functions as intended. Understanding where these components are located and how they contribute to the overall system will help operators manage performance and troubleshoot problems effectively.

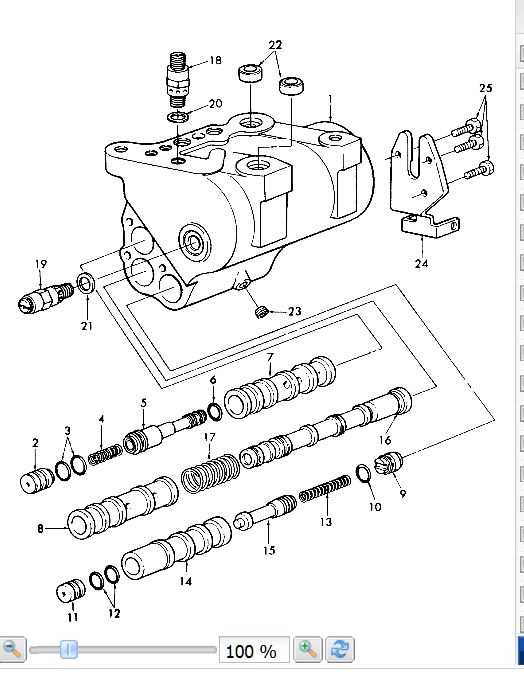

The engine, for example, is the powerhouse that drives the entire system, while the transmission system enables the machine to adjust speed and power based on different tasks. Another important component is the hydraulic system, which allows for the operation of various attachments and implements essential for performing agricultural work efficiently.

Identifying the location and function of each part within these systems can help prevent potential issues before they arise. Regular checks and familiarity with the layout will ensure smooth operation and prolong the life of the machine.

Understanding the Assembly and Layout

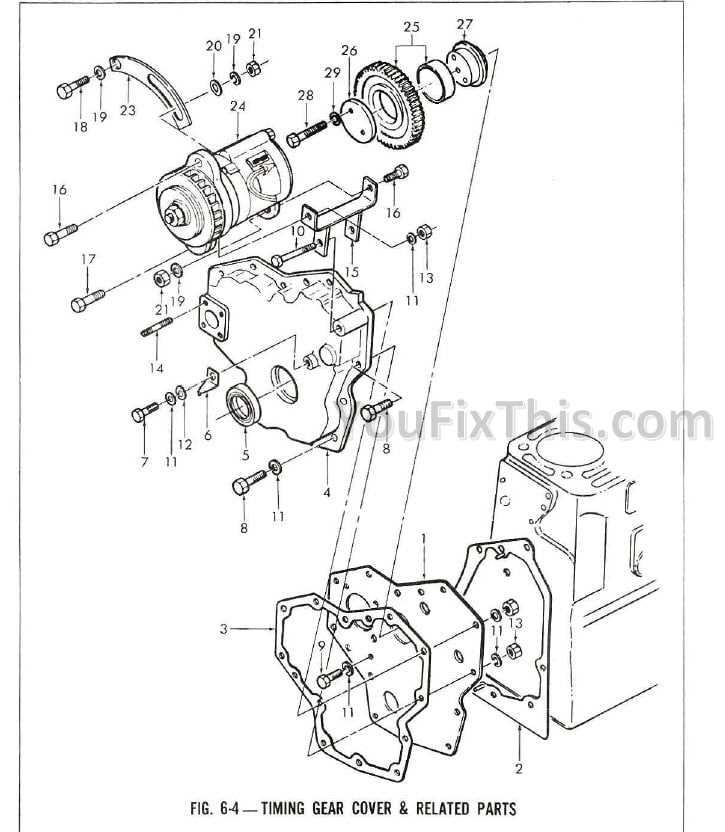

Grasping how the components of a heavy-duty machine are assembled and organized is crucial for its effective use and repair. Each system is carefully positioned to work in harmony, ensuring that the vehicle operates efficiently under various conditions. Knowing the overall arrangement of these elements allows for better understanding and troubleshooting when issues arise.

Component Arrangement

The machine’s structure is designed with specific priorities in mind, such as ease of access for maintenance and effective distribution of power. For example, the engine is strategically placed to connect seamlessly with the drivetrain, allowing for smooth power transfer to the wheels. Similarly, the hydraulic system is arranged to optimize the use of attachments, ensuring the efficient operation of implements attached to the vehicle.

System Interaction

The arrangement of components is not only about physical proximity but also about how they interact. Understanding how different systems, such as the fuel, electrical, and power transmission systems, communicate and work together helps in diagnosing problems and improving performance. A balanced layout ensures that no system is overworked, preventing premature wear and enhancing the overall longevity of the machine.