When working with complex machinery, it’s essential to have a clear understanding of the various elements that make up the device. A comprehensive guide to these components helps users recognize how everything fits together and functions as a whole. Proper knowledge of each part ensures that maintenance and repairs can be done efficiently.

Clear visual aids offer a way to better grasp the intricate structure of mechanical systems. These resources not only highlight the critical parts but also help in identifying specific areas that require attention. With an accurate representation, users can approach repairs with confidence and precision.

Whether you’re assembling, disassembling, or maintaining the equipment, a detailed understanding of its internal workings is invaluable. With the right guidance, even the most intricate tasks can be completed smoothly, ensuring that everything continues to operate at peak performance.

Exploring Stihl MS 461 Components

Detailed Diagram of MS 461 Parts

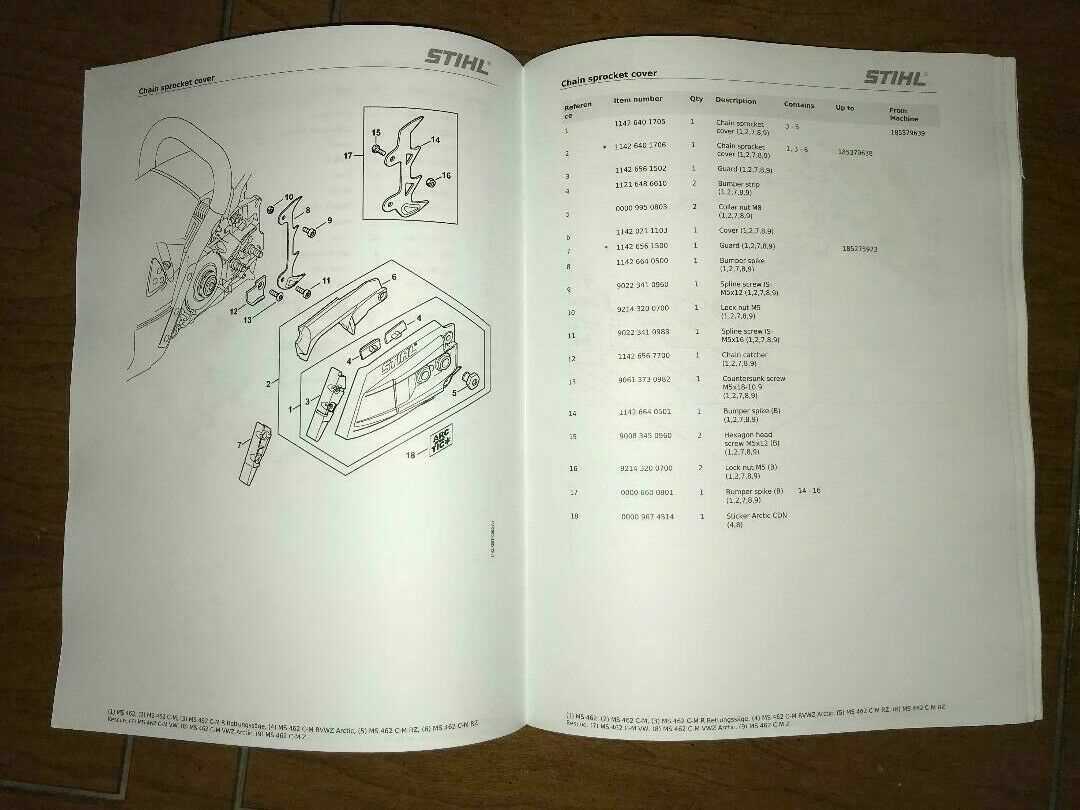

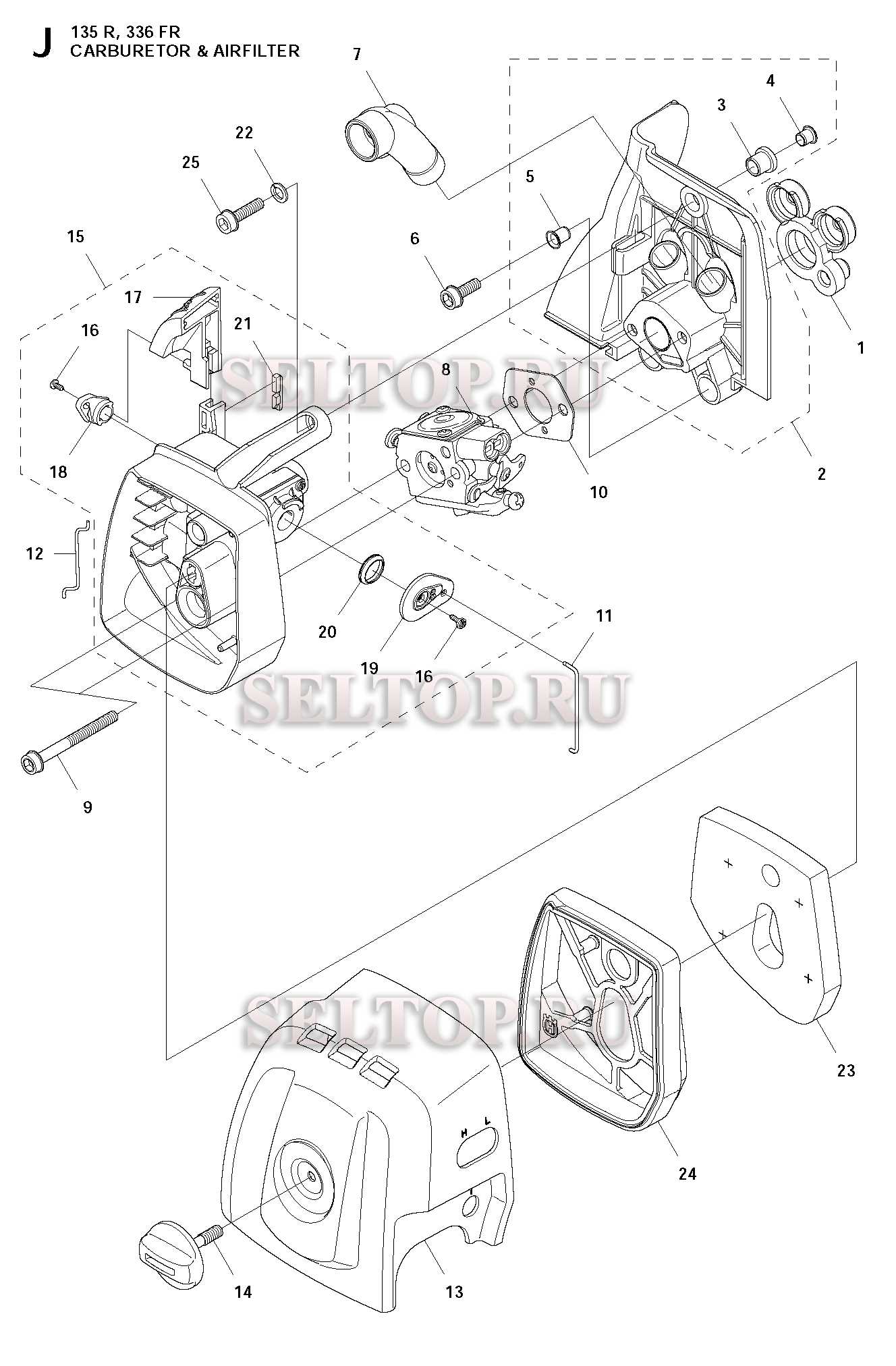

Understanding the internal structure of any machine is crucial for effective operation and maintenance. In this section, we will delve into the essential components that make up this specific model. Each piece plays a key role in ensuring the functionality and longevity of the device. By examining the layout of these elements, users gain insight into how everything interacts to perform complex tasks efficiently.

A visual representation of the mechanical structure provides clarity on where each component fits and how it contributes to the overall performance. This detailed breakdown serves as a valuable reference for anyone looking to maintain, repair, or upgrade their equipment. By recognizing the individual parts, users can make more informed decisions regarding care and troubleshooting.

From the engine housing to smaller internal components, understanding each part’s purpose and connection within the system enhances both preventative maintenance and repair efforts. Whether it’s identifying worn-out pieces or ensuring proper assembly, knowledge of the machinery’s inner workings is essential for extending its service life.

Assembling Stihl MS 461 Engine

Reassembly Instructions for the 461

Rebuilding a power tool engine requires precision and a clear understanding of each step in the process. Proper reassembly ensures optimal performance and minimizes the risk of future issues. This section provides a step-by-step guide to help users reassemble the engine correctly, ensuring that each component is placed accurately for smooth functionality.

Begin by carefully aligning the main housing and securing all internal components. Pay attention to the positioning of the crankshaft, pistons, and other vital elements that directly affect the power output. Each piece must be handled with care to avoid damage, and it’s essential to follow the manufacturer’s guidelines for proper torque and placement.

After assembling the internal mechanisms, focus on attaching the outer casing and verifying that all fasteners are tightly secured. Ensure that all connections, such as fuel lines and electrical components, are properly linked to avoid operational failures. Following these reassembly instructions step by step will help maintain the tool’s efficiency and ensure long-lasting use.

Maintaining Stihl MS 461 Components

Proper maintenance is crucial for extending the lifespan and enhancing the performance of any machinery. Regular checks and upkeep of key components help to prevent breakdowns and ensure smooth operation. This section highlights the importance of maintaining individual elements and provides essential tips for keeping them in optimal condition.

Routine Inspection and Cleaning

One of the most effective ways to prevent wear and tear is by performing routine inspections. Regularly check for signs of dirt, debris, and wear on the critical parts. Keeping components clean reduces the risk of clogging and ensures proper airflow and fluid circulation, which is vital for consistent performance.

Lubrication and Tightening of Components

Ensuring that moving parts are well-lubricated is another vital aspect of maintenance. Lubrication minimizes friction, which can lead to excessive wear. Additionally, always check the tightness of bolts, screws, and other fasteners to avoid loose parts that could cause malfunction or even damage the machinery.