When maintaining a sprayer, it is essential to have a clear understanding of its individual components. Knowing how each part contributes to the overall functionality can help with efficient repairs and upkeep. By recognizing the roles of various elements, users can quickly address any issues that arise and ensure the longevity of the device.

Knowing the essential features of the sprayer can save time during troubleshooting. Having access to a clear representation of its construction makes identifying specific parts straightforward, allowing you to focus on what needs attention. Whether for routine cleaning or part replacement, a thorough understanding of the device’s makeup is crucial.

While using the equipment, common problems may arise that require certain components to be checked or replaced. Familiarizing yourself with the internal structure can provide the confidence needed to handle such situations independently. With the right knowledge, you’ll be able to extend the life of your sprayer and enhance its performance.

Understanding the Key Components of Your Sprayer

To keep your sprayer functioning optimally, it is crucial to understand the different elements that make up the device. Each component plays a specific role in how the sprayer performs, and knowing these functions can help prevent malfunctions and improve overall performance. Identifying and understanding these elements ensures that maintenance and repairs can be done quickly and effectively.

The Main Elements of the Device

The device is made up of several core components that work in harmony to deliver a smooth spraying experience. From the motor to the nozzle, each piece contributes to the output and efficiency of the tool. Understanding the functions of these parts allows users to troubleshoot effectively when problems arise, and also aids in choosing the right replacement components when needed.

Why Component Awareness Matters

Awareness of each element within the sprayer can help with routine checks and repairs. Some parts, such as the air filters and nozzles, may need more frequent attention, while others might last longer without maintenance. Knowing which parts require regular upkeep will keep the device running efficiently for longer periods and reduce unexpected breakdowns.

How to Read the Components Illustration

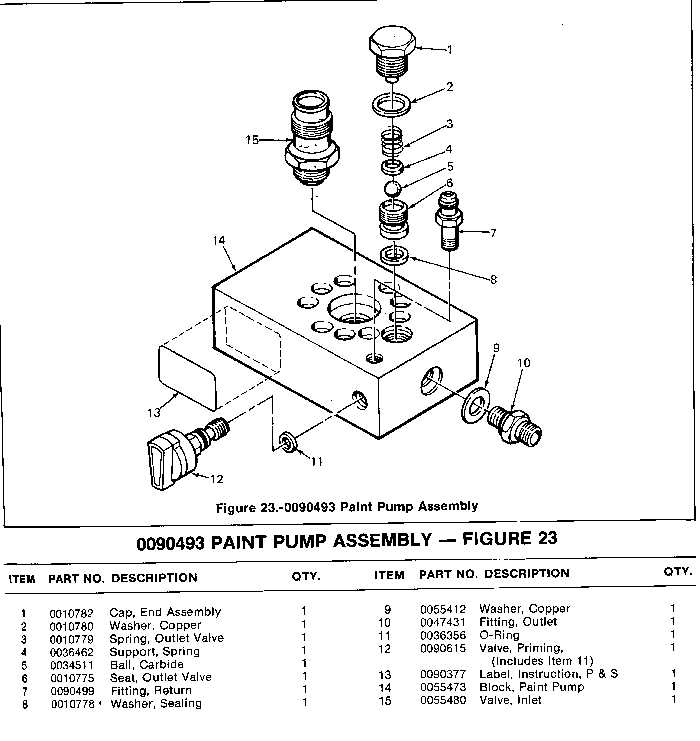

Understanding how to interpret the visual guide of your sprayer’s internal structure is essential for effective maintenance and repair. The illustration provides a detailed view of the various elements within the device, making it easier to identify and locate specific parts. This tool is invaluable when troubleshooting issues or replacing worn components.

Interpreting the Labels and Numbers

Each component in the visual guide is usually assigned a label or number for easy identification. These references are crucial when looking up specific details about a part or searching for replacements. Understanding these references allows users to match the part in the illustration with the actual component, ensuring accuracy during repairs.

Using the Illustration for Maintenance

Properly utilizing the illustration enables users to identify any damaged or worn-out components that need attention. It also highlights how each part fits together, which can help during assembly or disassembly. By consulting the guide, users can ensure their sprayer is reassembled correctly after maintenance, avoiding potential issues down the line.

Common Issues and Components Replacement

Over time, various problems may arise with your sprayer, often caused by wear and tear on certain elements. Understanding these common issues and knowing which components to replace can prevent major malfunctions and help maintain performance. Regularly addressing these problems can keep your device running smoothly for longer periods.

Typical Malfunctions and Their Causes

One of the most frequent issues is clogged nozzles, which can result in uneven spraying. This is often caused by dried paint or debris. Another common issue is a malfunctioning motor, typically due to dust or grease buildup. Identifying these problems early on can save time and prevent further damage to the device.

Replacing Worn or Damaged Components

Knowing which parts need replacing is key to restoring your sprayer’s functionality. Parts like filters, nozzles, and hoses are more prone to wear and should be replaced regularly. By following the manufacturer’s guidelines and referring to the component illustration, users can easily identify the parts that require attention and replace them correctly, ensuring optimal performance.