When working with heavy-duty machinery, having a clear understanding of its internal structure is crucial for proper maintenance and repair. Knowing each individual component and how they interact can save time and enhance performance. A detailed guide allows users to navigate the complexity of these tools with ease, ensuring that every part is correctly identified and maintained.

In this section, we explore the essential elements of a powerful chainsaw, from the engine to the smallest fasteners. By becoming familiar with the overall layout and the function of each part, operators can avoid common issues and keep their equipment running smoothly. Accurate identification and replacement of worn or broken parts are vital for prolonging the life of any machine.

Emphasizing precision in repairs, the guide will help you understand how to handle each component safely and effectively. Whether you are a professional or a DIY enthusiast, having the right information at hand is the key to ensuring your equipment works at its best.

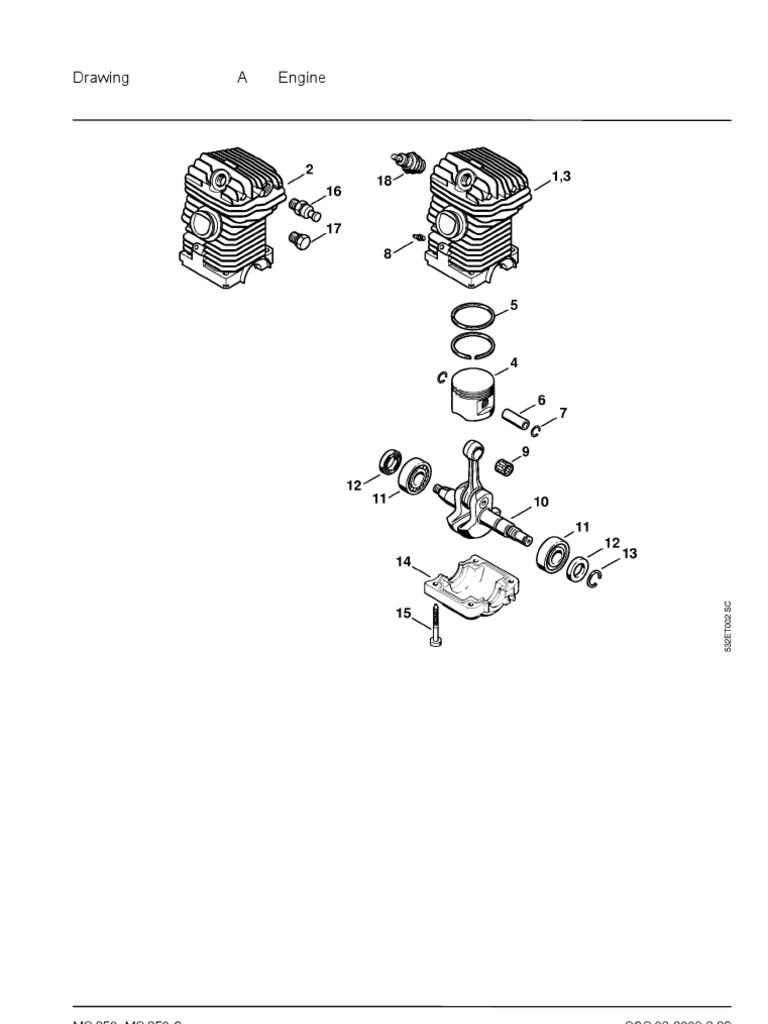

Understanding Stihl 066 Chainsaw Components

Every high-performance cutting tool is made up of various essential elements that work together to ensure smooth operation. By understanding the individual components and their functions, you can maximize the efficiency and longevity of your equipment. Knowing how each part interacts within the system allows for better troubleshooting and maintenance practices.

Key Components of a Chainsaw

- Engine – The powerhouse of the tool, providing the necessary energy to operate all functions.

- Bar and Chain – The cutting elements, crucial for precise and efficient cuts.

- Fuel System – Ensures proper fuel delivery to the engine for continuous operation.

- Drive Mechanism – Transfers power from the engine to the chain for movement.

- Safety Features – Includes elements like chain brakes and anti-vibration systems for safer handling.

How to Identify and Replace Parts

Accurate identification of components is key to effective repairs. Over time, wear and tear can lead to the degradation of certain parts, requiring replacement. Here’s how to ensure you’re choosing the right components:

- Refer to a detailed parts reference guide to match the correct components with your tool model.

- Inspect each part for signs of wear, such as cracks, corrosion, or unusual movement.

- Ensure replacements are compatible in terms of size, function, and material to maintain the tool’s performance.

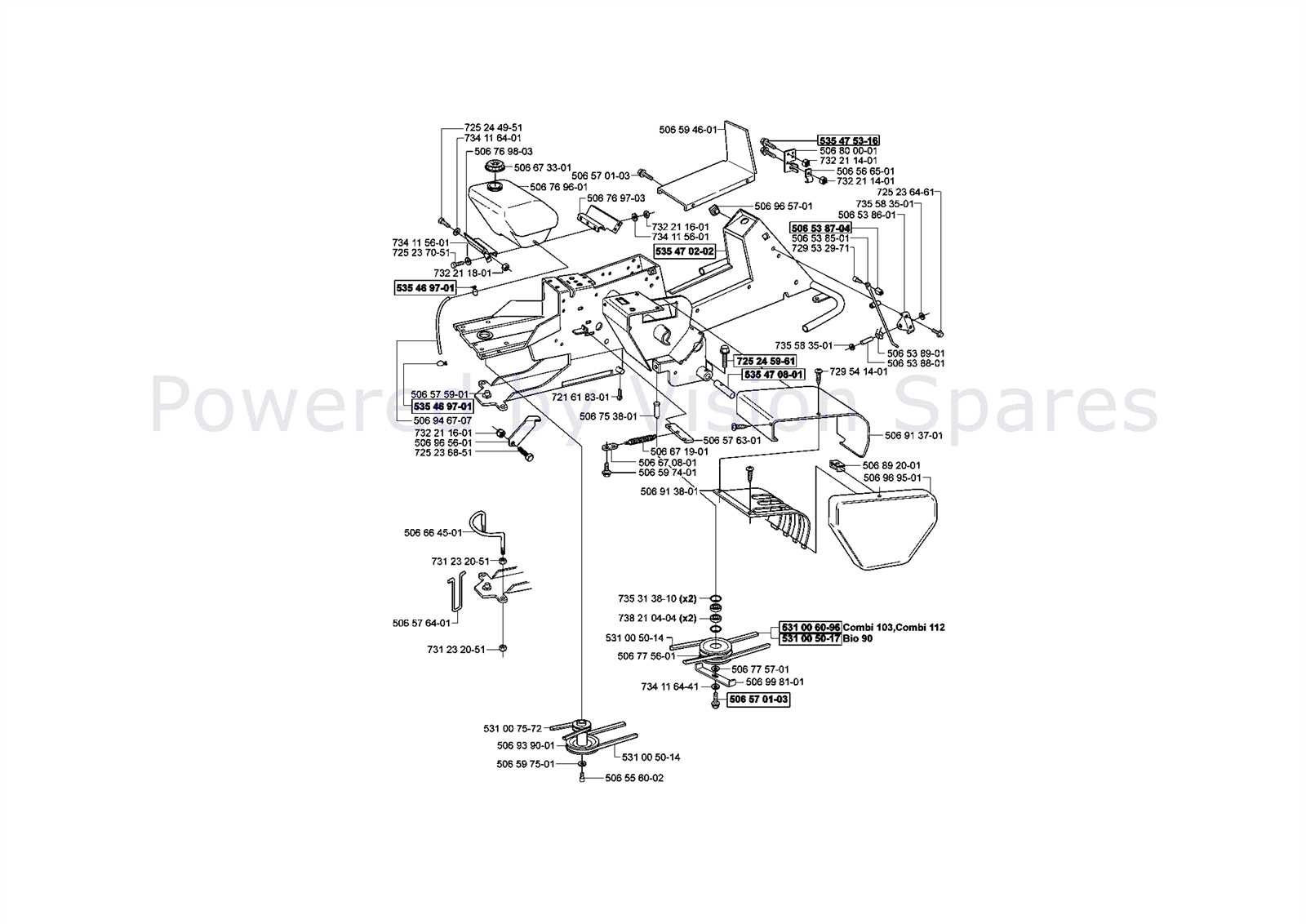

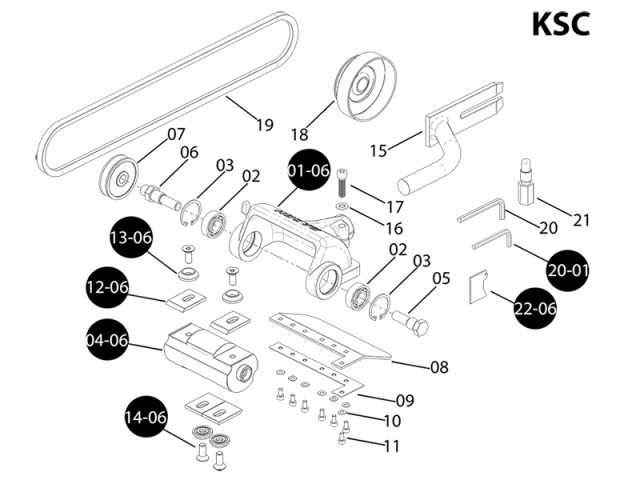

How to Use the Stihl 066 Diagram

Using a detailed reference guide for your tool can greatly enhance your ability to perform accurate repairs and maintenance. By following a visual map of the tool’s internal and external components, you can identify each element and understand how they function together. This guide is especially helpful when disassembling or reassembling the machine for maintenance tasks.

Step-by-Step Identification Process

- Begin by locating the main sections of the tool on the reference guide.

- Identify each part in relation to its position in the overall structure.

- Use the visual guide to pinpoint parts that may need repair or replacement based on wear and tear.

Using the Guide for Repairs

Once you’ve identified the necessary components, the guide can also help you during the repair process. It ensures you understand how to disassemble and reassemble the tool correctly:

- Disassembly: Start with the basic framework and move systematically, following the visual cues.

- Reassembly: Once the parts are replaced or repaired, the guide will show the correct order for reassembly to ensure everything functions properly.

Essential Parts for Stihl 066 Maintenance

To keep any powerful cutting tool in optimal condition, it’s important to focus on key components that are subject to wear over time. Regular maintenance ensures that each part continues to perform at its best, preventing breakdowns and extending the life of the machine. Familiarizing yourself with the most crucial elements for upkeep is the first step toward effective maintenance.

Critical Components for Regular Maintenance

- Fuel System: Ensures proper fuel delivery to the engine, which is vital for smooth operation. Regular checks and cleaning can prevent fuel blockages.

- Bar and Chain: The cutting mechanism must be kept sharp and well-lubricated to ensure efficient cutting performance. Lubrication is essential to reduce wear.

- Air Filter: Keeps dirt and debris from entering the engine. Replacing or cleaning the air filter regularly helps maintain engine efficiency.

- Drive Mechanism: Transfers energy from the engine to the chain. Proper maintenance ensures smooth operation and reduces strain on the engine.

Signs of Wear and When to Replace

Knowing when components need replacement is essential for maintaining peak performance. Here are some signs that indicate a part may need attention:

- Engine performance: Reduced power or difficulty starting can be a sign of clogged fuel filters or a worn ignition system.

- Chain movement: If the chain moves sluggishly or gets stuck, it could indicate a need for chain lubrication or a worn sprocket.

- Excessive vibration: Often caused by loose or damaged components, this can reduce comfort and precision when operating the tool.