Understanding how to maintain and repair your outdoor power tool is crucial for its longevity and performance. Every machine consists of various components that work together, and knowing their exact placement and function can save time and money when troubleshooting or replacing parts.

Accurate identification of each part is key to successful repairs. By exploring the layout of the components, users can gain a better understanding of how each element interacts and contributes to overall functionality. This knowledge is invaluable for ensuring that your tool runs smoothly and efficiently.

In this guide, we will break down the necessary steps and provide a clear overview of how to approach maintenance and repairs. By following these tips, you can enhance your machine’s performance and avoid unnecessary downtime.

Understanding the Equipment Layout

Knowing the structure and arrangement of the components in any outdoor machine is essential for efficient troubleshooting and maintenance. A well-organized layout allows users to identify specific elements, understand their roles, and pinpoint issues without unnecessary guesswork. This approach helps in performing quick repairs and ensures proper functioning over time.

Component Breakdown

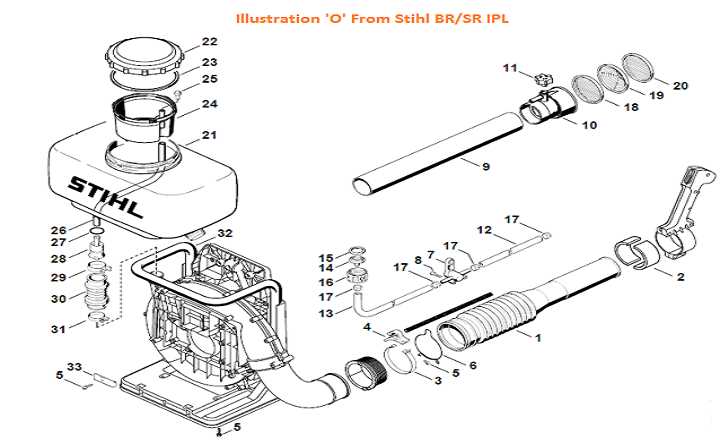

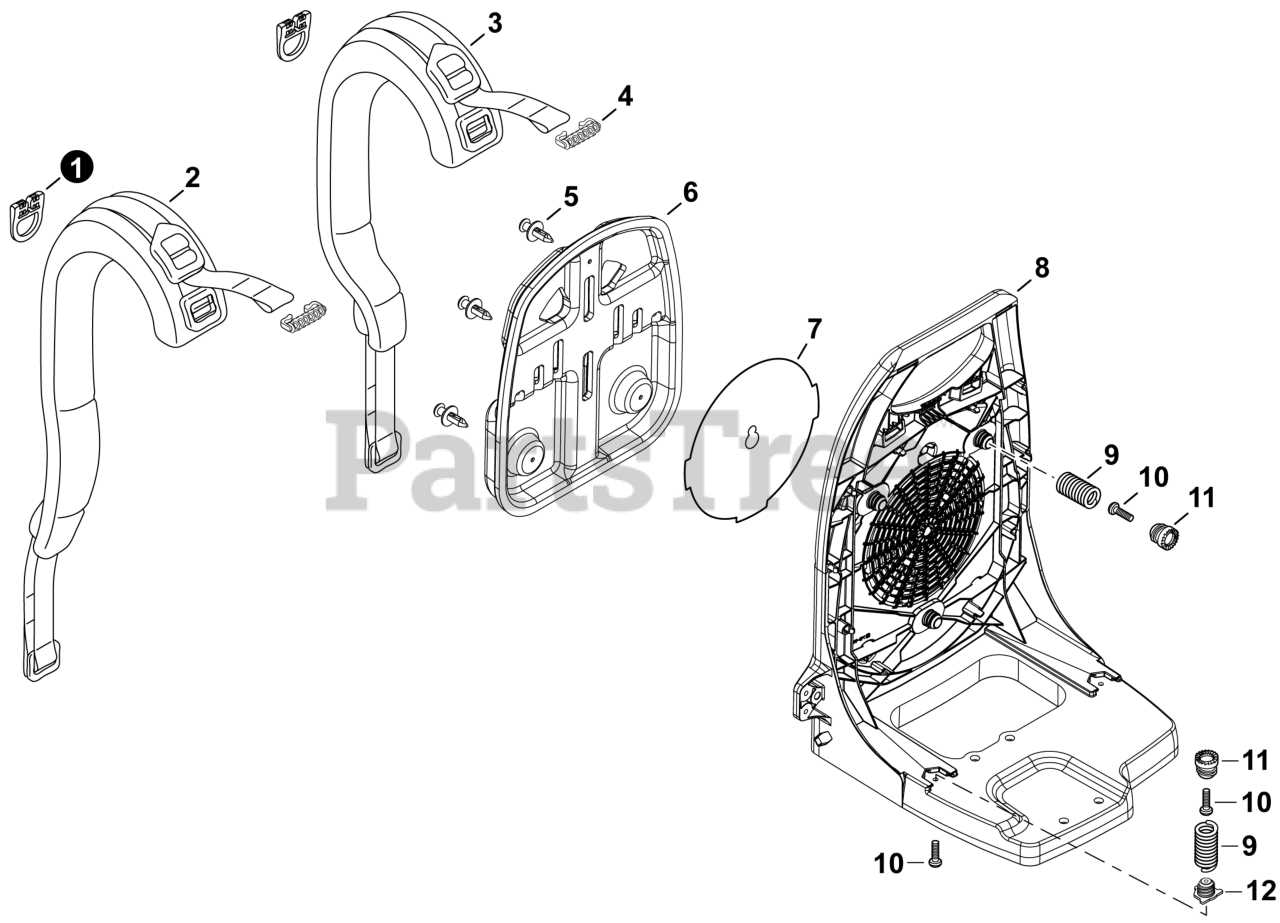

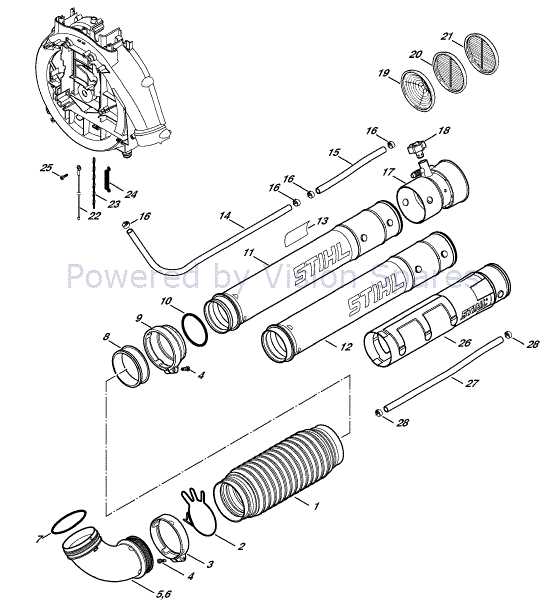

The layout typically includes various sections, such as the power system, control mechanisms, and safety features. Each part is designed to serve a unique function, from starting the engine to controlling airflow or vibrations. By studying the arrangement of these parts, you can gain insight into how they interact, and make informed decisions during repairs.

Identifying and Replacing Components

Once you familiarize yourself with the configuration of your equipment, you can more easily identify worn-out or damaged parts. Accurate identification not only aids in replacing faulty components but also helps in purchasing the right replacements. The ability to efficiently replace broken pieces ensures your equipment performs at its best and extends its operational lifespan.

Common Components and Their Functions

Every machine relies on a variety of essential components that work together to ensure smooth operation. Each element plays a crucial role in maintaining the performance and efficiency of the equipment. Understanding the function of these components is key to successful maintenance and timely repairs.

Power System

The engine is at the heart of any outdoor tool, providing the necessary energy for the machine to function. It works in conjunction with the fuel system, which ensures that the engine receives a consistent supply of energy. Regular maintenance of these systems ensures optimal power output and prevents malfunctions during operation.

Control Mechanisms and Safety Features

Control features, such as the throttle and trigger, are essential for regulating the machine’s speed and power output. These components allow users to operate the tool safely and efficiently. Additionally, safety mechanisms such as the brake and guard help protect the user from potential injuries, providing peace of mind during operation.

How to Use the Layout for Repairs

Using a well-structured layout can greatly simplify the repair process. When troubleshooting issues or replacing malfunctioning components, having a clear guide of the machine’s structure helps identify the root cause of the problem quickly. This process reduces errors and ensures that only necessary parts are replaced or repaired.

Step-by-Step Repair Process

Start by carefully reviewing the layout to locate the malfunctioning component. Identify the part’s position and understand its relationship with neighboring components. This will help you determine if there are any connected parts that may also require attention. Once you’ve pinpointed the issue, proceed with the appropriate steps to remove or replace the part, following safety guidelines to avoid further damage.

Efficient Part Replacement

When replacing components, ensure you have the correct parts by cross-referencing the layout. This ensures compatibility and prevents unnecessary disassembly. Properly follow the sequence of steps for reassembly, paying close attention to the position and alignment of each part. This organized approach leads to more efficient repairs and restores the machine’s functionality without complications.