When working with complex machinery, having a clear understanding of its key elements is essential for proper maintenance and efficient operation. The visual representation of a machine’s structure serves as a helpful guide for identifying each part and its function within the system. A comprehensive overview of these components allows operators and technicians to ensure that everything is functioning correctly and address any issues that arise.

Accurate identification of specific components is crucial for troubleshooting, repairs, and upgrades. Knowing where each piece fits within the larger system can save time and prevent mistakes. Utilizing an informative guide not only simplifies the process but also enhances the overall reliability of the equipment, ensuring it performs at its best over time.

By carefully studying the layout and understanding the roles of different components, operators can take a more hands-on approach to maintaining their equipment. This knowledge also helps in minimizing downtime, improving productivity, and avoiding unnecessary expenses related to improper maintenance.

Understanding Essential Machine Components

Effective operation of heavy machinery depends on the careful integration of various critical elements. Each part plays a specific role in ensuring that the entire system runs smoothly and performs its tasks efficiently. Recognizing the function of these individual components and how they interact with each other is essential for anyone involved in maintenance, repair, or troubleshooting.

Core Functional Elements

The core components of a machine work in harmony to deliver optimal performance. Understanding how each element contributes to the overall function can aid in detecting faults or areas that may require attention. A thorough knowledge of these systems makes it easier to diagnose issues and implement necessary repairs, ultimately extending the machine’s lifespan.

Identifying Parts for Maintenance

Regular inspection and upkeep are vital to prevent breakdowns and ensure that all elements continue to function as expected. Recognizing the location and role of each key piece enables technicians to pinpoint wear and tear, replace damaged components, and perform adjustments. This proactive approach reduces downtime and enhances the longevity of the equipment.

Identifying Key Components for Maintenance

Recognizing the crucial elements of any machinery is vital for effective upkeep. Understanding which components directly impact the machine’s functionality helps technicians target the right areas for inspection and servicing. Regularly assessing these key parts allows for proactive maintenance, reducing the risk of unexpected failures and improving the overall performance of the equipment.

For an efficient maintenance routine, it is essential to focus on parts that bear the most strain during operation. These components typically include the engine, hydraulic system, and transmission, among others. Regularly checking their condition ensures that the equipment continues to run smoothly, avoiding costly repairs or downtime caused by neglecting critical areas.

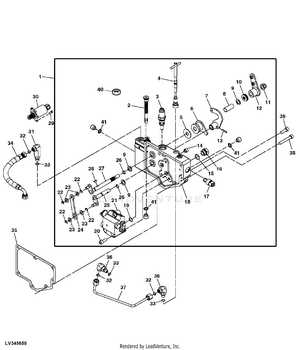

How to Use the Parts Breakdown Effectively

Utilizing a visual breakdown of machine components is an essential skill for anyone performing maintenance or repairs. Such diagrams provide a clear, organized representation of how parts are arranged, making it easier to locate and identify specific elements. A well-structured breakdown allows technicians to work efficiently, ensuring that each part is properly addressed during service or troubleshooting.

Step-by-Step Approach

Start by familiarizing yourself with the entire structure presented in the diagram. Identify the main assemblies and follow the logical flow of the system. This method helps to understand the relationship between components, making it easier to isolate issues or target specific areas for attention during maintenance.

Accurate Identification and Replacement

Once the key components are identified, use the breakdown to find the exact part numbers and descriptions. This ensures that the correct replacement parts are selected, avoiding errors during the repair process. It is crucial to cross-check all information to ensure that the right elements are being serviced, reducing the risk of future complications.