Proper maintenance of farming machinery is essential to ensure smooth operation and longevity. Knowing the essential components and how they function together plays a crucial role in troubleshooting and performing repairs effectively.

Identifying specific elements within the machine and understanding their roles allows for quicker and more accurate maintenance. Whether replacing worn-out items or adjusting settings for optimal performance, understanding each part’s function is key to success.

In this guide, we will explore the various components of your equipment, providing you with valuable insights to help you maintain and repair it efficiently. With the right knowledge, you can ensure that your machinery operates at peak performance year after year.

Understanding the Hesston 1091 Haybine Parts

Every piece of machinery in the agricultural sector is composed of several critical elements that contribute to its efficiency. Familiarizing yourself with these components is essential to maintaining functionality and avoiding unexpected breakdowns during use. Each individual part has a unique purpose, and together, they form a cohesive system that ensures the machine works as expected.

Key Components of the Machine

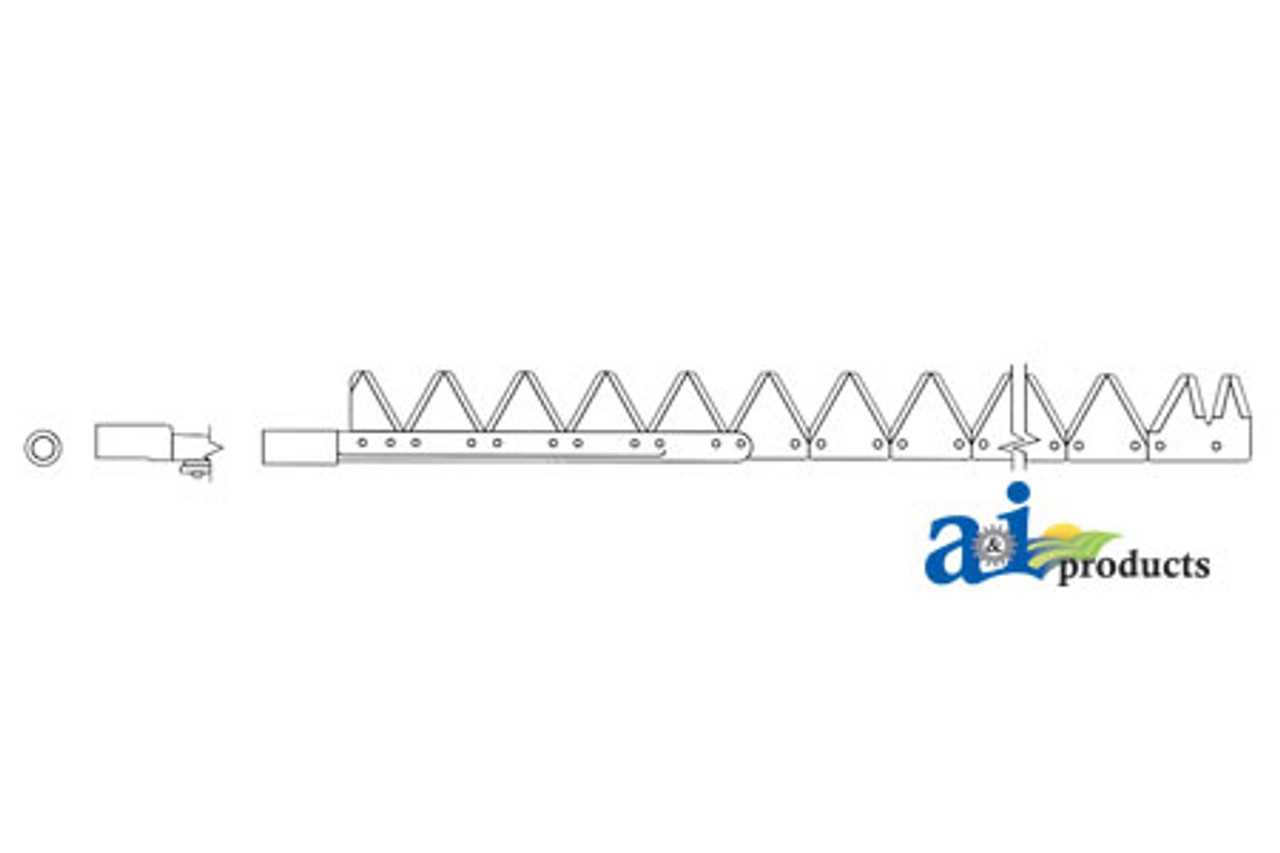

The main components of this equipment are designed to handle specific tasks that aid in the overall operation. Some parts are responsible for cutting, while others assist with transport or adjustment. Identifying these key elements helps in diagnosing issues and ensuring the proper functioning of the machine over time. A deeper understanding allows for more informed decisions regarding repairs and upgrades.

Maintenance and Care for Long-Term Use

Regular upkeep and replacement of worn components are vital for extending the life of the machine. Even minor issues can have a significant impact on overall performance, which is why understanding each part’s function is crucial. Through proper maintenance, you can avoid costly repairs and keep the machine running smoothly throughout its lifespan.

Key Components for Efficient Operation

For any piece of agricultural machinery to operate efficiently, each component must perform its specific role seamlessly. When all the elements are in top condition, the machine runs smoothly and can deliver the expected results in a timely manner. Understanding these key components ensures that any issues can be quickly identified and addressed before they lead to larger problems.

From the cutting mechanism to the transport system, every part of the equipment is designed to work together. Regular inspection of these critical elements helps maintain performance and avoid interruptions. Whether it’s ensuring the blades are sharp or the drive system is functioning properly, each piece plays a vital role in the overall efficiency of the machine.

How to Identify and Replace Parts

Proper identification and timely replacement of worn or damaged components are essential for keeping farming equipment in optimal working condition. Recognizing signs of wear or malfunction early can prevent costly repairs and extend the life of the machine. This process involves both visual inspection and understanding the function of each element in the system.

Step-by-Step Identification Process

Before replacing any component, it’s crucial to identify the specific issue. Follow these steps to ensure accurate detection:

- Start by checking the overall condition of the machine and listening for unusual sounds during operation.

- Inspect key areas such as the cutting mechanism, drive system, and transport parts for visible wear or damage.

- Consult the user manual for guidance on the common problems and their associated symptoms.

Replacing the Worn Components

Once the faulty parts are identified, it’s important to replace them with the correct replacements. Follow these steps to ensure proper installation:

- Ensure the replacement components are compatible with the machine model.

- Carefully remove the damaged parts, paying attention to any screws or fasteners that may need to be loosened or removed.

- Install the new components, securing them tightly and checking for proper alignment before testing the machine.

By following these steps, you can effectively identify and replace any damaged or worn parts, ensuring your equipment remains in excellent condition and operates efficiently for years to come.