Maintaining and repairing machinery can often be a daunting task, especially when you’re faced with unfamiliar parts. Having a clear visual representation of the internal components is essential for both new and experienced users. It simplifies the process of identifying faulty or worn-out pieces, ensuring that your equipment runs efficiently.

By referring to detailed diagrams, you can quickly pinpoint which parts need attention, allowing you to take the necessary steps for repair or replacement. This process not only helps in saving time but also reduces the risk of making costly mistakes during maintenance. A comprehensive guide offers a practical approach to understanding how each piece fits within the overall structure, facilitating smoother operations.

In this article, we’ll explore how to effectively utilize such visual guides for various machinery models, helping you become more confident in performing upkeep and repairs. With the right knowledge, you can keep your tools running smoothly for longer periods of time.

Toro 21465 Parts Breakdown Overview

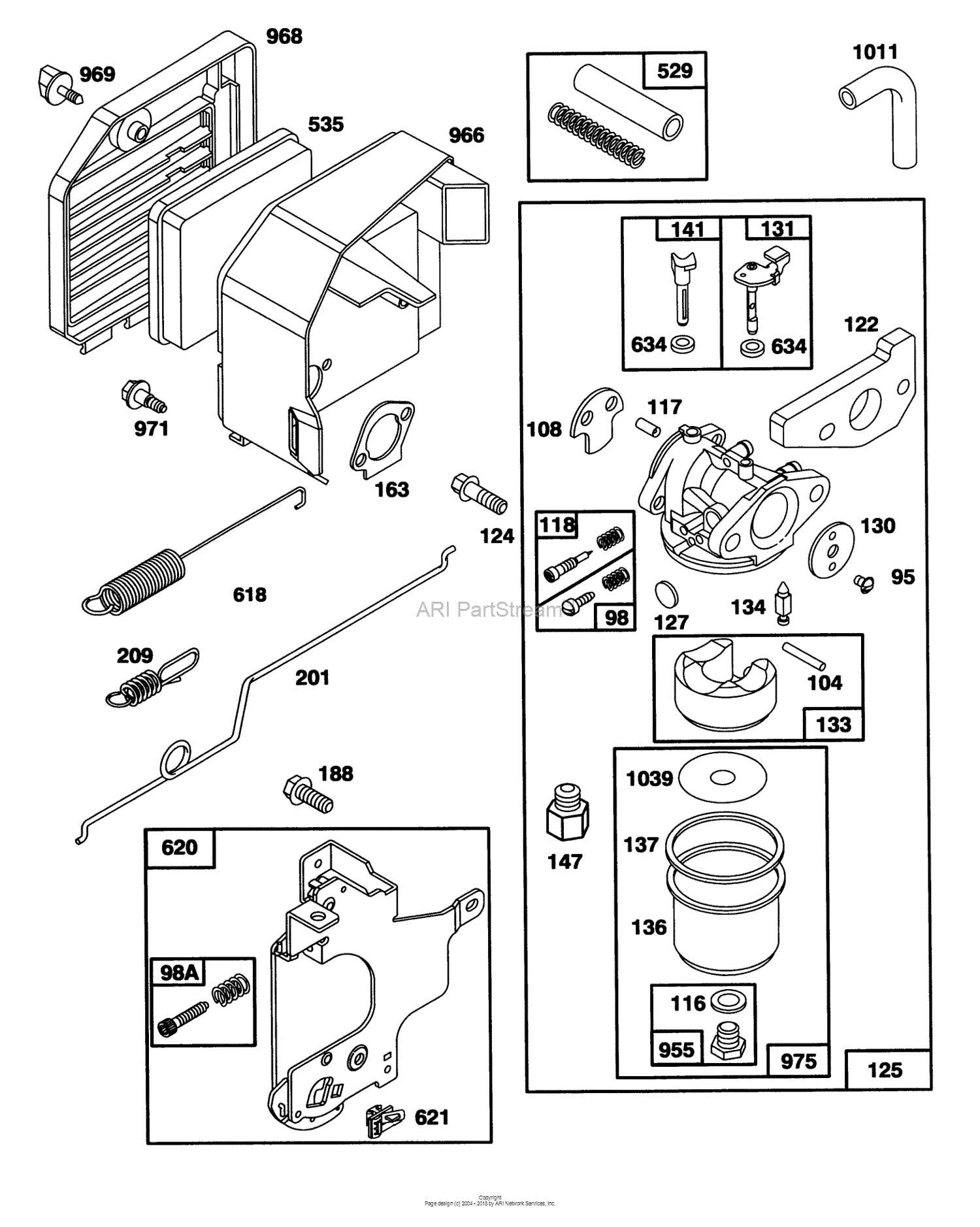

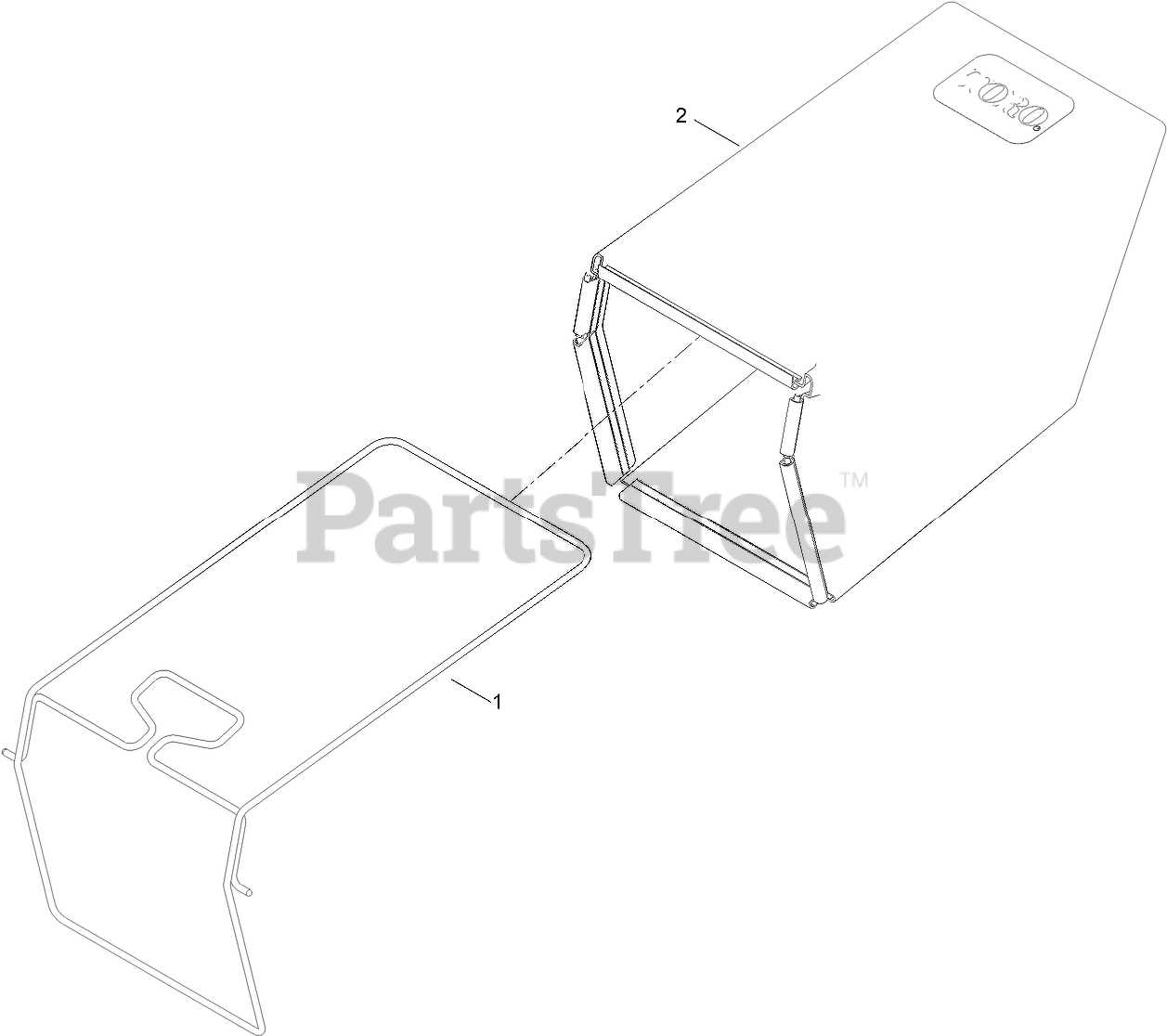

Understanding the individual components of machinery is crucial for proper maintenance and efficient operation. A comprehensive breakdown provides clarity on how each element functions within the system and helps identify potential issues. This process is particularly valuable when troubleshooting or replacing damaged parts, as it ensures that every component is addressed correctly.

By examining the assembly, users can see the relationship between each part, from the smallest fasteners to the more complex mechanical elements. This knowledge enables more precise repairs and replacements, minimizing downtime and ensuring that the equipment performs at its best. Proper identification also reduces the risk of using incompatible components, which could cause further damage or inefficiency.

Having a well-organized visual guide allows you to follow the layout step by step, making it easier to understand where each piece fits. This overview not only supports repairs but also aids in the overall maintenance strategy, ensuring your machinery continues to deliver optimal results throughout its lifespan.

How to Use Toro 21465 Parts Diagram

Utilizing a visual guide for equipment maintenance is an essential skill for effectively managing repairs and replacements. These diagrams offer a clear layout of all key components, helping users identify and address any issues with precision. Knowing how to interpret these visuals is the first step toward ensuring your machinery stays in top condition.

Step-by-Step Guide for Interpretation

Start by locating the section of the visual that corresponds to the area you need to inspect or repair. Each part will be numbered or labeled, providing easy identification. Follow the provided reference to match each piece to the corresponding description or part number. This will ensure that you are focused on the correct components for the task at hand.

Common Tips for Effective Use

When working with a visual reference, it’s important to keep a clear understanding of the layout to avoid confusion. Break the diagram down into smaller sections, and tackle one at a time. Additionally, it’s useful to keep a record of part numbers for future reference in case replacements are needed. Accuracy is key to a successful repair process.

Common Toro 21465 Replacement Parts

When maintaining or repairing equipment, certain components are more prone to wear and tear than others. Knowing which pieces are commonly replaced can help streamline the repair process and ensure that the machinery continues to perform optimally. Some parts are essential for the operation, while others are more vulnerable to damage over time.

Frequently Replaced Components

Among the most common items that need replacement are mechanical elements such as belts, blades, and filters. These parts often experience regular stress and can degrade faster due to frequent use. Regular inspection and timely replacement of these items can help prevent further damage to other components and maintain the overall performance of the machine.

Additional Essential Replacements

In addition to the more obvious components, smaller parts such as seals, gaskets, and fasteners should also be kept on hand for replacements. These items play a crucial role in maintaining the integrity of the machine, preventing leaks or malfunctioning. Having a stock of these replacements ensures that you are always prepared to handle any unexpected breakdowns or maintenance needs.