Maintaining and repairing complex machinery requires a clear understanding of its internal mechanisms. Knowing how each element fits together ensures efficient operation and minimizes downtime. Properly recognizing and handling each individual component is essential for long-term performance.

Illustrations and detailed charts are invaluable tools in this process, offering a visual representation of how parts connect and interact. These resources help owners and technicians identify parts quickly, allowing for more informed decisions during maintenance and repairs.

Whether you are an experienced mechanic or a beginner, grasping the layout of critical components and their functions enhances the ability to troubleshoot effectively. A well-organized reference guide can save time and reduce the risk of errors, ensuring smooth operation and prolonging the lifespan of the equipment.

Dixie Chopper Silver Eagle Parts Overview

Understanding the essential elements that contribute to a machine’s function is crucial for effective maintenance. Every piece plays a specific role, and identifying them allows for efficient troubleshooting and repairs. Familiarity with the machinery’s core components provides insight into how to keep everything running smoothly and efficiently.

Critical Components of the System

The key components that keep the equipment operational include the engine, transmission, and various mechanical parts responsible for movement. Each of these elements requires regular inspection to ensure optimal performance. An overview of these components helps users identify where potential issues may arise and guides the necessary steps for maintenance or replacement.

Importance of Regular Inspection

Routine checks and timely replacements are essential for maintaining the system’s reliability. By keeping track of wear and tear, users can avoid major breakdowns and extend the lifespan of their equipment. Knowing which elements to monitor allows for preventative actions, reducing the need for costly repairs in the future.

Understanding Key Components of the Silver Eagle

Every machine relies on a set of core components that ensure its functionality. These essential elements work together to drive performance and provide reliability. Knowing how each part contributes to the whole system helps users perform routine maintenance and troubleshooting tasks more efficiently.

Engine and Power Mechanism

The engine is the heart of any mechanical system, generating the necessary force to propel the machine. It connects to other critical parts, such as the transmission, to transfer power smoothly. Regular maintenance of the engine ensures consistent operation and minimizes the risk of sudden failures.

Transmission and Drive System

The transmission is responsible for adjusting the power delivered by the engine to match the required movement speed. The drive system, including belts and gears, ensures this power is properly distributed across the machine. Keeping these components in good condition is vital for preventing mechanical failures and optimizing performance.

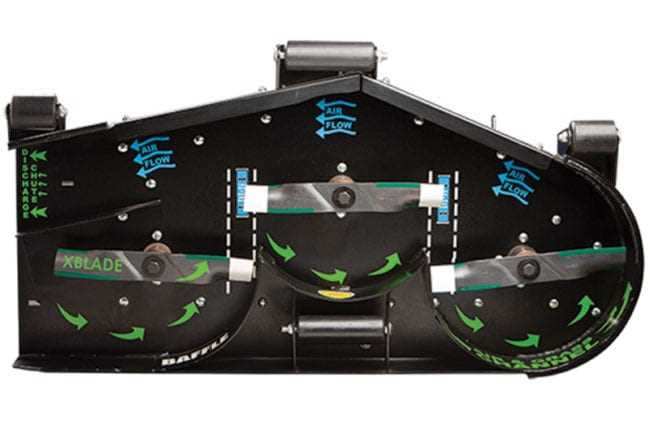

How to Use the Parts Diagram Effectively

Understanding how to read and interpret visual references is essential for any maintenance or repair task. These guides provide clear images and labels that show how individual components interact within the system. Knowing how to navigate these resources makes troubleshooting and repairs more efficient and accurate.

Identifying Key Components and Their Functions

The first step in using a visual guide effectively is recognizing the different components shown. Each element is typically labeled with a number or code that corresponds to a detailed list of specifications. Familiarizing yourself with these labels allows you to easily locate and identify any parts you may need to replace or inspect.

Understanding Connections and Relationships

A proper understanding of how each part connects within the system is crucial. The diagrams often highlight these relationships, showing how power or movement flows through the machine. This helps in diagnosing issues and ensures that when parts are replaced, they are installed in the correct configuration to maintain functionality.