Every heavy-duty machine relies on a series of interconnected components that work together to ensure smooth functionality. Understanding how these elements interact is crucial for proper operation and efficient maintenance. The mechanical setup behind these machines is intricate and essential for achieving their full potential on job sites.

By examining the individual sections that make up the structure, operators can gain valuable insight into the system’s design. Knowledge of these critical components helps identify any issues early, preventing costly repairs and maximizing performance.

Proper knowledge of the inner workings allows for quicker troubleshooting and more effective maintenance. Familiarity with the layout and connection points provides a solid foundation for anyone working with this machinery, whether for regular servicing or upgrades.

Understanding the Components of a Skid Steer

The functionality of any compact machinery is determined by a wide array of crucial elements that work in unison. Each component has a specific role, contributing to the overall performance and efficiency of the machine. To fully appreciate how this machinery operates, it is important to explore the different sections and understand how they are interconnected.

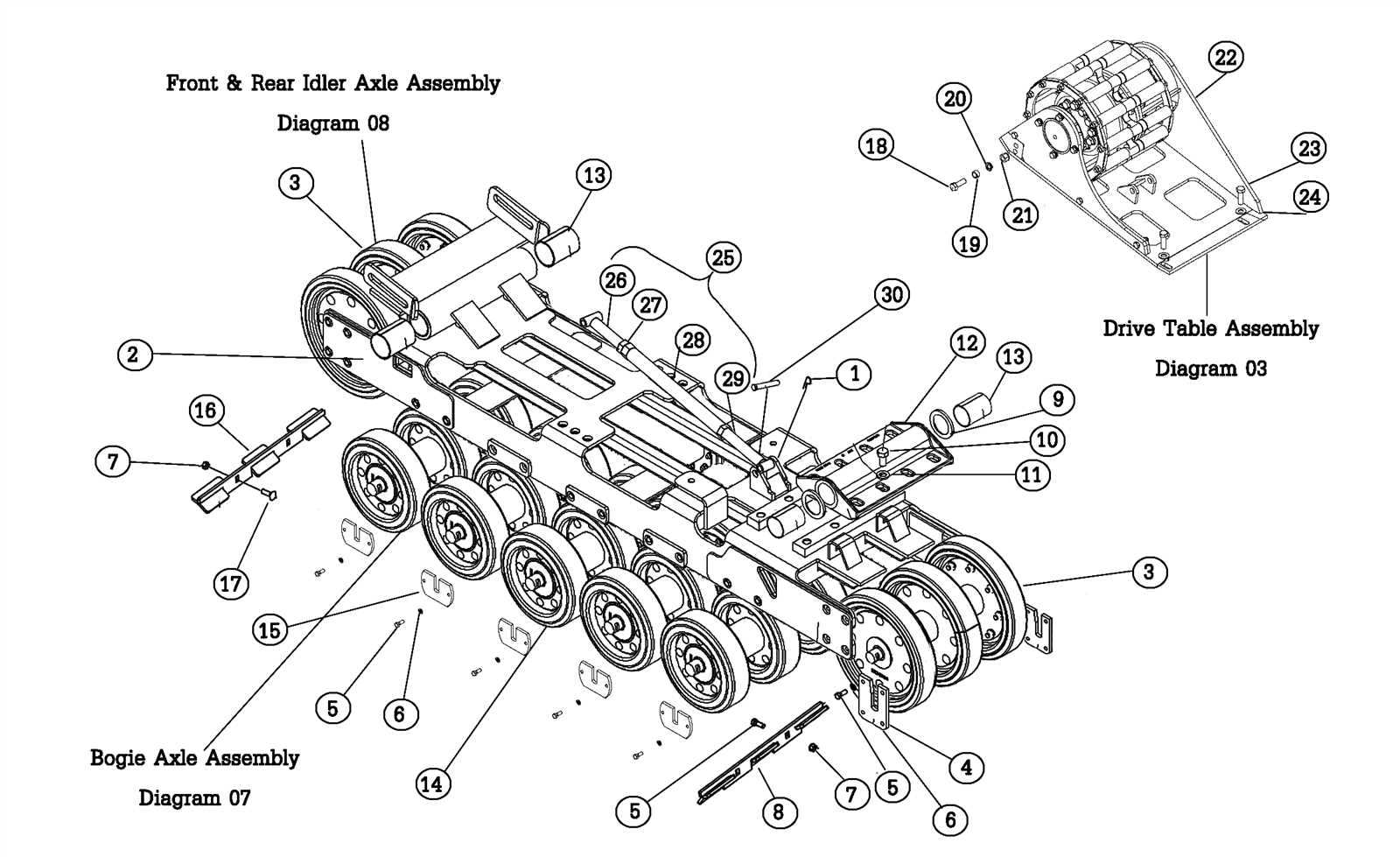

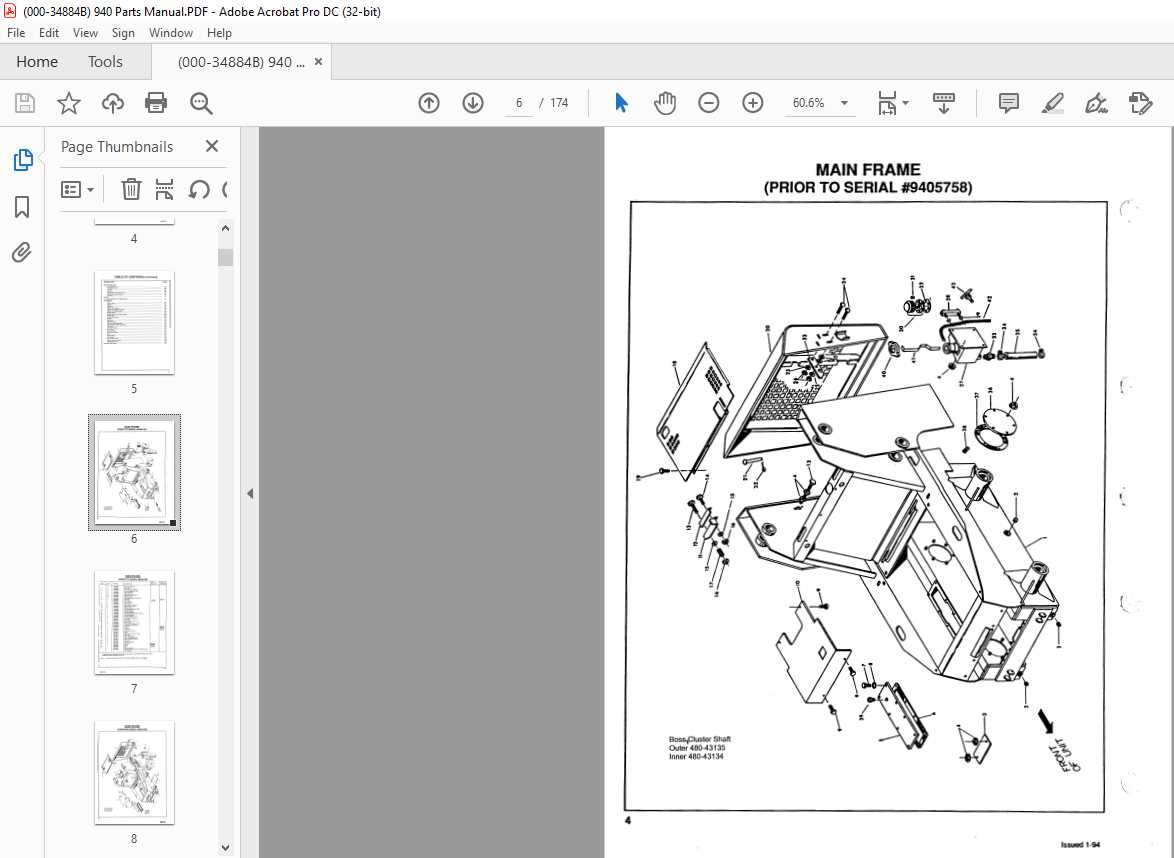

In these machines, the core mechanisms include drive systems, hydraulic components, and the structural frame, all of which allow for dynamic movement and effective load handling. The control systems and the interface between the operator and the machine are just as significant, as they ensure precision and safety during operation.

Each element has a distinct function that supports the machine’s versatility and durability in challenging work environments. Knowing these components is essential not only for daily operation but also for maintenance and troubleshooting. By understanding how they interact, operators can ensure smooth operation and address issues before they become serious problems.

How to Identify Skid Steer Parts

Recognizing the different components of machinery is essential for proper maintenance and repair. Whether you’re performing a routine check or troubleshooting an issue, knowing how to identify individual sections makes the process more efficient. By understanding the function of each part, you can quickly pinpoint problems and avoid unnecessary downtime.

Step-by-Step Identification Process

To begin identifying the key elements of the machine, it’s important to focus on the following steps:

- Examine the Frame: Start by inspecting the frame, as it holds the core components together and provides the structure for the entire system.

- Check the Hydraulic System: This system controls movement and power, making it one of the most vital parts of the machine.

- Understand the Drive Components: The drive components, including the wheels or tracks, allow for movement and traction across various surfaces.

- Look at the Control Mechanisms: The controls, including levers and joysticks, interact with the other elements, translating operator commands into action.

Commonly Identified Components

Some components are easier to spot than others. Here are a few common parts to identify:

- Engine: The powerhouse of the machine that drives all other systems.

- Bucket or Attachment: These elements are designed to handle the load and perform specific tasks.

- Axles and Tires: Responsible for mobility, these components provide stability and control.

With practice, identifying and understanding these components will become second nature, ensuring better handling and quicker response to maintenance needs.

Maintenance Tips for Skid Steer Parts

Proper maintenance of machinery components is essential for ensuring longevity and peak performance. Regular upkeep helps prevent unexpected breakdowns and costly repairs. By following a few simple tips, you can extend the life of the key systems and keep your equipment running smoothly, even in the most demanding conditions.

One of the most important practices is to regularly inspect and clean the machine’s components. This not only keeps dirt and debris from causing wear but also helps identify any potential issues before they become serious problems. Additionally, lubricating moving parts reduces friction, ensuring smoother operation and preventing premature wear.

Pay attention to the hydraulic system and its fluid levels. Low fluid levels can affect performance and lead to damage, so topping up regularly is essential. Also, check the filters and replace them as needed to ensure the fluid stays clean and the system functions properly.

Finally, be proactive about tire or track condition. Maintaining proper tire pressure or ensuring the tracks are properly tensioned helps improve stability and performance, while also extending the lifespan of these essential components.