In order to effectively use a spray tool, it’s essential to understand how its different elements work together. Each part plays a specific role, contributing to the overall performance of the tool. Gaining knowledge of these components helps improve technique and ensure smooth operation.

Familiarizing yourself with the internal structure allows for more efficient maintenance and troubleshooting. Recognizing the function of each piece also aids in selecting the right equipment for specific tasks, whether for detailed artwork or larger projects.

By understanding the key elements, users can achieve better control, accuracy, and longevity in their tool’s performance. Proper knowledge of how everything fits together also empowers users to make necessary repairs or adjustments when needed.

Essential Components of an Airbrush

To achieve precise control and optimal performance with any spray tool, understanding its core elements is crucial. These key components work in unison to ensure consistent results and functionality. Knowing how each piece contributes to the overall mechanism can improve both the user experience and the final outcome of any project.

Flow Control Mechanisms

The flow control system regulates the release of the medium, allowing the user to adjust the intensity and smoothness of the application. This feature is vital for achieving varying effects, from fine details to broader coverage. By mastering this control, users can tailor the output to suit specific tasks, whether for intricate designs or larger areas.

Air Supply System

The air supply is responsible for propelling the medium through the tool. A steady and consistent airflow is necessary for maintaining even spray patterns and avoiding inconsistencies. The design and quality of the air supply mechanism directly impact the tool’s efficiency and ease of use during both short and long sessions.

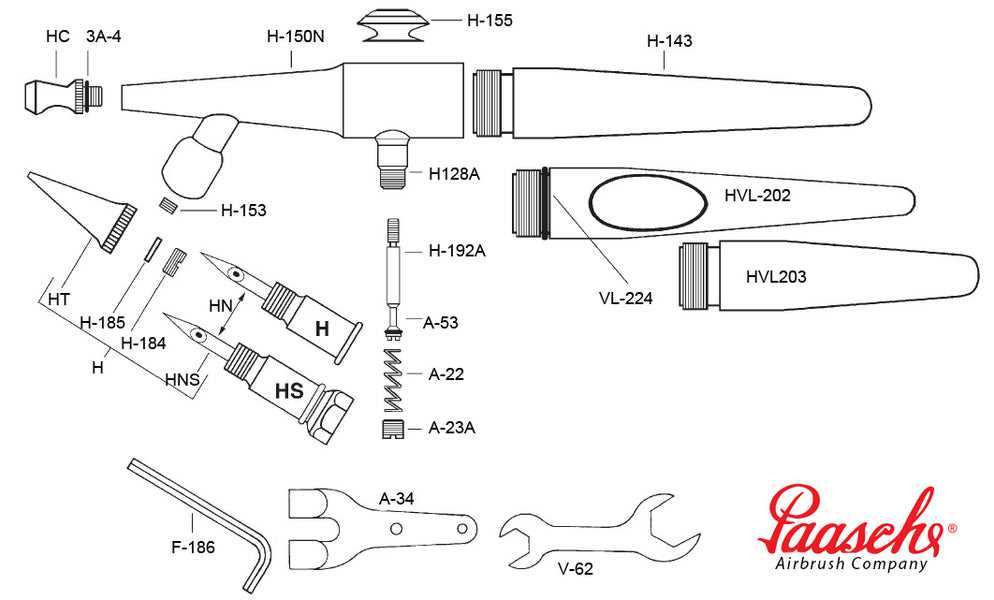

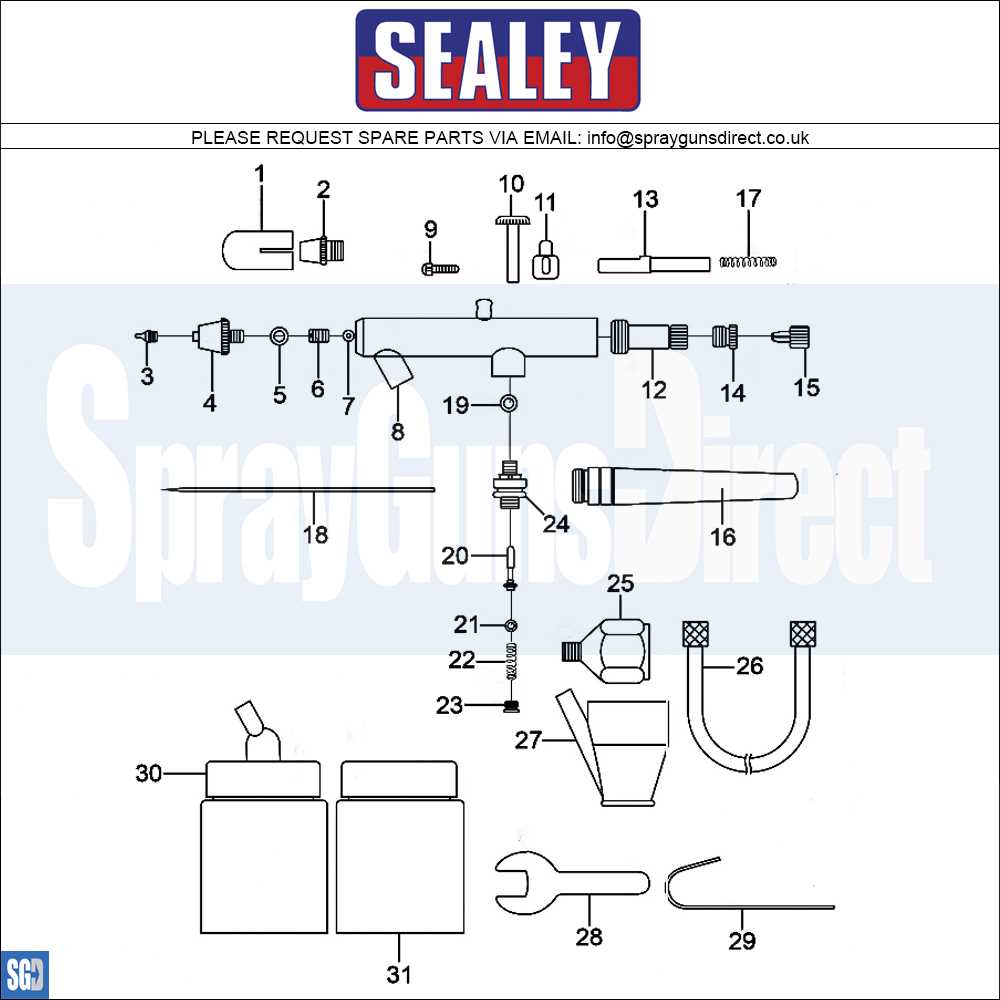

How to Identify Airbrush Parts

Recognizing the different components of a spray tool is essential for understanding its functionality and maintaining it effectively. By learning how to identify each individual element, users can enhance their technique and ensure smoother operation. Knowing what each part does helps to troubleshoot issues, perform repairs, and make adjustments when necessary.

One of the most straightforward ways to identify the components is by familiarizing yourself with their shape, size, and placement within the tool. Each piece typically serves a distinct role, from regulating the flow of the medium to controlling the air pressure. Some components are easily visible, while others may require disassembly or a closer look to properly identify.

Airbrush Assembly and Maintenance Tips

Proper assembly and regular maintenance are crucial for ensuring long-lasting performance and consistent results from your spray tool. By following a few key steps, you can maintain your equipment’s efficiency and avoid common issues that may affect its operation. Knowing the correct procedure for assembly and upkeep will extend the life of your tool and improve overall functionality.

Assembly Guidelines

When assembling your tool, it’s important to carefully follow the manufacturer’s instructions to ensure each component fits together correctly. Misalignment can lead to leaks or uneven airflow, causing inconsistent results. Be sure to securely attach all pieces, including seals and nozzles, to prevent air or medium from escaping during use.

Regular Cleaning and Maintenance

Regular cleaning is essential to keep your tool in top condition. After each use, disassemble the tool and thoroughly clean all parts, especially the nozzle and air inlet. A buildup of residue can impair performance, leading to clogging or uneven spray patterns. It’s also important to lubricate moving parts as needed and check for any wear or damage that may require repair or replacement.