Maintaining and repairing your sewing machine can be challenging without the right guidance. Understanding its internal components and how they fit together is essential for ensuring long-term performance. In this section, we will explore how to navigate and interpret the essential visuals that map out the different elements of your machine.

Knowing the key components of your machine can save time and effort during troubleshooting. With the correct visual representation, you can easily identify parts that need replacing or cleaning, ultimately improving your machine’s functionality.

Whether you’re a beginner or an experienced user, learning how to properly assess your machine’s structure is an important step in maintaining its optimal condition. By following a clear and concise breakdown of these details, you can make more informed decisions when handling repairs and maintenance tasks.

Understanding Sewing Machine Components

To keep your sewing machine in top condition, it’s crucial to understand the various elements that work together to provide smooth operation. Each component plays a specific role in the functioning of the machine, and recognizing their purpose can make troubleshooting easier.

Key components such as the motor, needle, and bobbin housing are essential for the overall performance. Familiarity with their arrangement and how they interact ensures proper handling during maintenance or repair procedures. Understanding where these components are located can save you time and frustration when it comes to performing routine checks or identifying issues.

In addition to the visible elements, some internal mechanisms, like gears and belts, are often overlooked but are equally important. Gaining knowledge of these hidden parts helps you recognize potential wear and tear before it becomes a major problem. By examining the machine’s inner workings, you ensure that every piece is functioning at its best, contributing to the overall efficiency of your sewing tasks.

How to Read the Parts Diagram

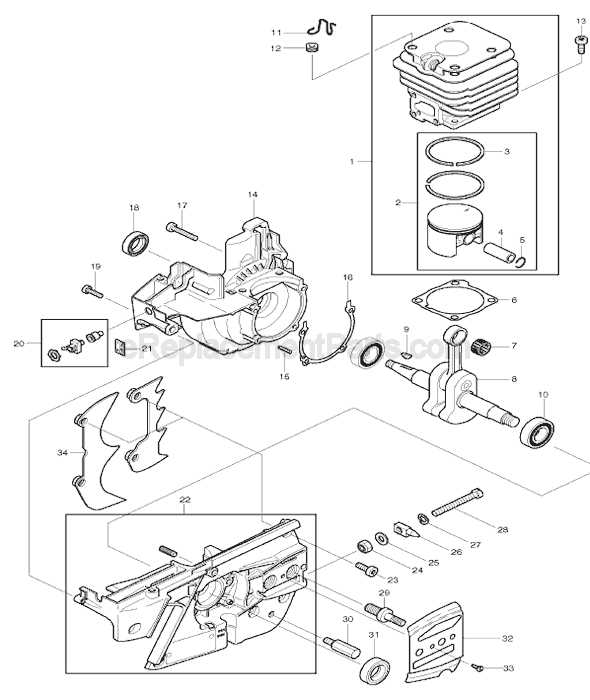

Understanding how to interpret a machine’s visual representation is key to successful maintenance and repair. These visuals provide a detailed map of the machine’s structure, helping you locate individual elements and understand their functions. Knowing how to read this type of guide ensures you can identify the correct components when needed.

Start by familiarizing yourself with the labels on the diagram. Each part is typically numbered or marked with a specific reference, making it easier to connect the visual with the machine’s physical layout. Pay attention to any accompanying notes or descriptions that explain the function or significance of each part.

Additionally, focus on the layout and flow shown in the diagram. Often, components are displayed in an order that reflects the machine’s assembly or operation. By following this sequence, you’ll be able to troubleshoot effectively, understanding how the parts work together and which ones may need attention or replacement.

Essential Parts for Machine Maintenance

Proper maintenance of a sewing machine requires attention to its most critical components. These key elements ensure smooth operation and should be regularly checked for wear or damage. Familiarizing yourself with the essential components is vital for keeping the machine in peak condition.

The needle is one of the most important parts to monitor. Over time, it can dull or bend, which affects stitching quality. Regularly replacing the needle is an easy way to prevent issues.

Another crucial element is the bobbin case. It houses the bobbin and ensures the thread is fed properly into the machine. Keeping it clean and free from debris will help prevent operational problems.

Additionally, the feed dogs, which move fabric through the machine, should be kept clean and free from lint. Regular inspection of these components, along with other smaller parts like the tension discs and motor belts, can go a long way in maintaining your machine’s performance.