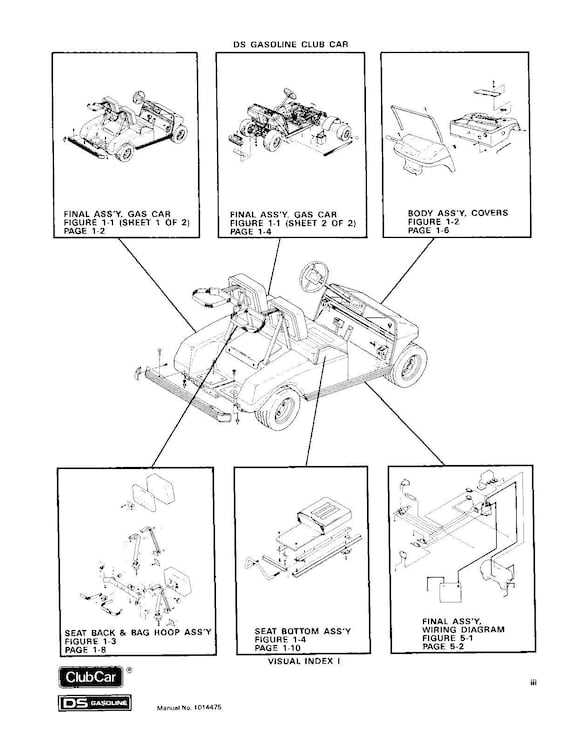

Understanding the intricate details of your vehicle’s assembly is essential for efficient maintenance and repair. Each system within the machine is made up of a series of interconnected elements that work together to ensure smooth operation. Knowing these elements, their function, and how they interrelate can greatly enhance the ability to troubleshoot issues effectively.

By referring to a detailed breakdown of the vehicle’s structure, you can identify potential wear and tear, understand replacement needs, and perform timely maintenance. A well-organized schematic is an invaluable tool that helps both experts and enthusiasts in handling repairs, ensuring the longevity of the machine.

Whether you’re replacing a specific component or seeking to optimize overall performance, having a clear understanding of the system’s parts and their roles will lead to better decisions and smoother repairs. This guide offers a closer look at how to navigate and use these detailed illustrations for maximum benefit.

Understanding Vehicle Component Breakdown

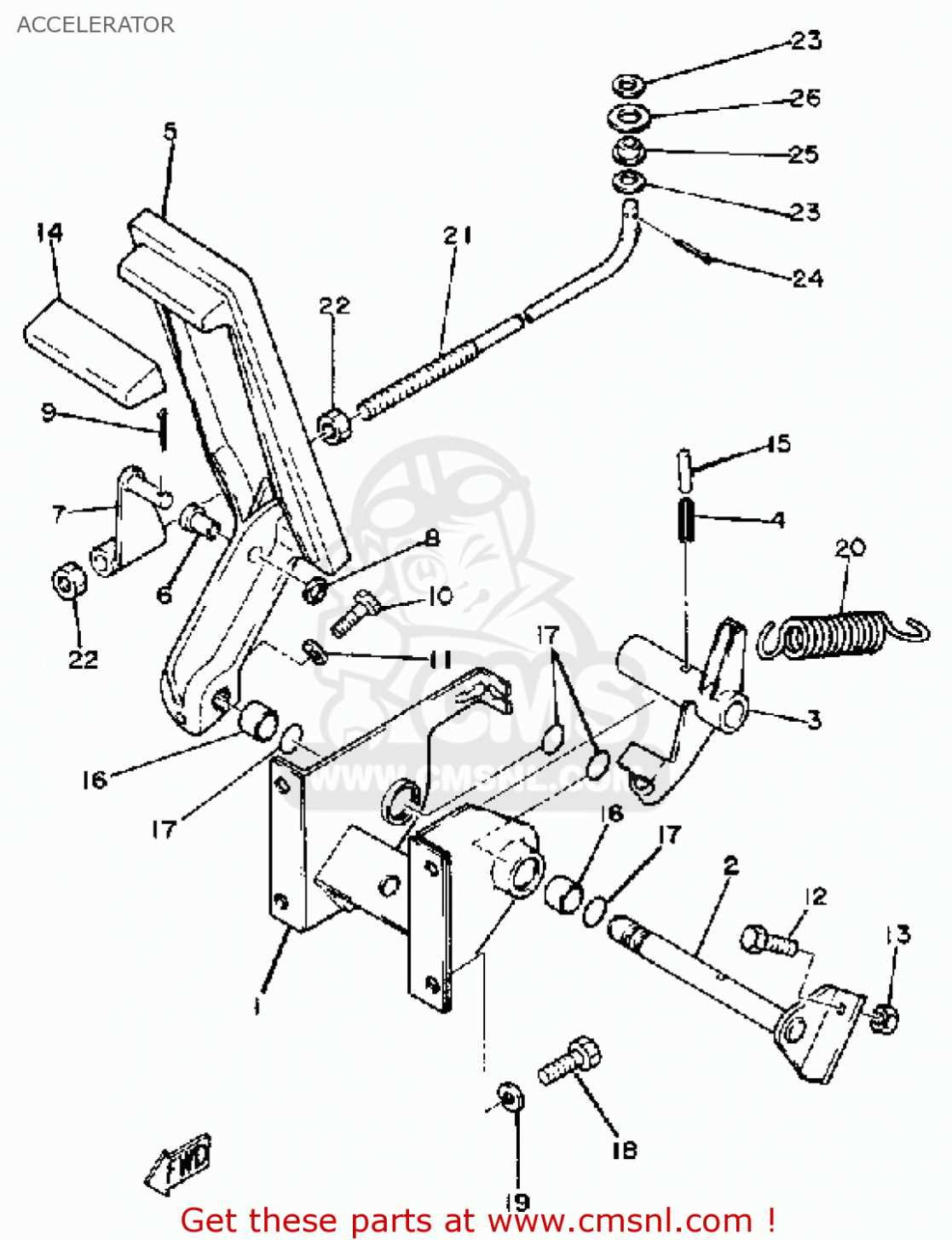

A thorough understanding of a vehicle’s system components is crucial for anyone involved in its maintenance or repair. The intricate web of interconnected parts, each with a specific function, ensures that the entire machine operates seamlessly. Recognizing the role of each individual element and how it interacts with others helps in diagnosing problems and making informed decisions about repairs or replacements.

Key Systems and Their Roles

Vehicles are designed with multiple systems that work together to support overall functionality. Each system, whether related to power delivery, suspension, or electrical functions, is composed of various components that must function properly to maintain performance. Familiarity with these systems allows you to quickly identify when something is malfunctioning and where to look for solutions.

Common Wear and Tear Indicators

Over time, components experience wear and tear due to regular use. Understanding how to spot the early signs of damage or reduced efficiency is essential for extending the life of your vehicle. Routine inspections, guided by a comprehensive understanding of each component’s structure, can prevent unexpected breakdowns and ensure your machine stays in optimal condition for longer periods.

Essential Parts for Vehicle Maintenance

To keep any machine running efficiently, it’s important to focus on key components that require regular attention. These essential elements are responsible for the overall performance and reliability of the vehicle. Identifying and maintaining these critical components ensures smooth operation and minimizes the risk of costly repairs down the line.

Critical Components to Monitor

There are certain systems within the vehicle that demand more frequent checks. The engine, electrical system, and suspension are some of the primary areas that need regular inspection and upkeep. Ensuring that these systems remain in optimal condition can prevent unexpected breakdowns and improve the overall lifespan of the vehicle.

Maintenance Tips for Longevity

Proper maintenance goes beyond just replacing parts when they fail. Regular cleaning, lubrication, and timely servicing are all essential practices that contribute to the durability of critical components. By taking the time to follow manufacturer recommendations and utilizing quality replacement parts, you can avoid unnecessary wear and ensure that the vehicle operates efficiently for years to come.

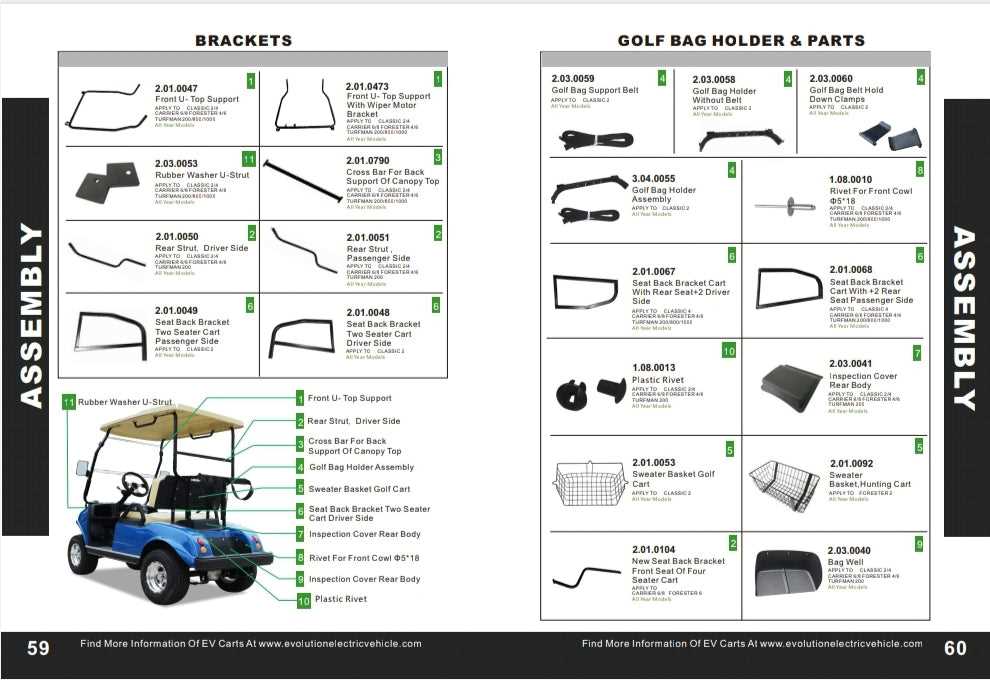

How to Identify Replacements for Vehicle Components

Identifying when a component needs to be replaced and choosing the right replacement can be a challenging task. Understanding the exact specifications of each part and recognizing the signs of wear and tear is key to making the right choice. This ensures the longevity of the vehicle and maintains optimal performance.

Steps for Identifying Replacements

Before replacing any component, it’s important to go through a few basic steps to ensure compatibility and effectiveness:

- Inspect the current condition of the component to determine if replacement is necessary.

- Check for manufacturer recommendations regarding compatible replacements.

- Cross-reference the part number with trusted resources or catalogs for proper identification.

- Ensure that the replacement component matches the original specifications in size, material, and functionality.

Common Mistakes to Avoid

When replacing vehicle components, it’s easy to overlook certain factors. To avoid common mistakes:

- Don’t use generic parts that may not meet the required standards.

- Avoid skipping the inspection process; this could lead to misidentification of faulty components.

- Ensure all parts are from a reliable and reputable source to guarantee quality.