Maintaining outdoor power equipment requires a solid understanding of its individual components and how they work together. A detailed overview of each part ensures efficient repairs and replacements, helping you extend the lifespan of your tools.

Whether you are looking to fix a malfunction or simply want to improve the performance of your device, knowing the right pieces and how to assemble them is essential. This guide will help you identify critical elements, offering step-by-step instructions to assist in every maintenance task.

Familiarizing yourself with the key components of your equipment can save time and money, making the repair process straightforward. Explore the most common parts and their functions, and learn how to troubleshoot or replace them with ease.

Understanding Trimmer Components

To ensure optimal performance and longevity of your lawn tool, it’s essential to understand the various elements that make it function. Each component plays a crucial role, from the motor to the cutting mechanism, and knowing how they interact can make repairs or upgrades easier. This section provides insight into the main components you should be familiar with for proper maintenance and care.

Key Elements and Their Functions

Each tool consists of several key components that work together to perform the desired task. The engine drives the motor, while the shaft transmits power to the cutting head. Understanding the function of these components will help you identify any potential issues and make informed decisions when performing maintenance or replacements.

Common Issues and Solutions

Common problems that arise with these tools often stem from wear and tear on certain components. Whether it’s a faulty ignition system or a damaged cutting head, knowing how to address these issues can prevent further damage. Regular checks and replacements can ensure your equipment stays in top working condition for years to come.

How to Identify Key Components

Identifying the essential elements of your equipment is crucial for effective maintenance and troubleshooting. By recognizing each component and understanding its function, you can quickly spot any issues that may arise. This knowledge allows for smoother repairs, part replacements, and better overall care of your tools.

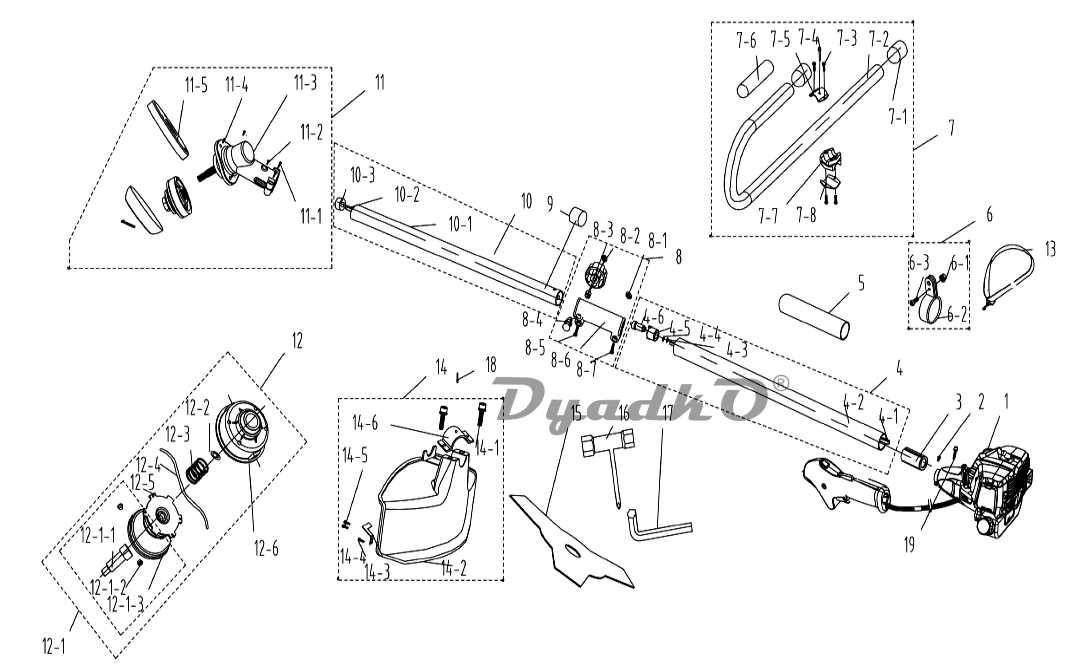

Visual Inspection for Quick Identification

The first step in identifying the core components is a thorough visual inspection. Carefully examine the exterior and interior of your tool to locate the key parts. The motor, cutting head, and shaft are typically the most important areas to check. By familiarizing yourself with their appearance, you’ll be able to recognize when something is out of place.

Using Reference Guides for Accuracy

Sometimes, it’s difficult to identify parts without additional guidance. Using reference materials like owner’s manuals or part lists can help ensure you’re targeting the correct elements. These resources offer detailed diagrams and descriptions, allowing you to match visual observations with specific components.

Step-by-Step Assembly Instructions

Assembling your tool correctly is essential for its efficient operation. A step-by-step guide can simplify the process, ensuring that each component is in place and functions properly. Following precise assembly instructions helps prevent errors and extends the lifespan of your equipment.

Start by carefully reviewing each component to ensure all necessary pieces are available. Begin with the motor and secure it to the main frame, ensuring that all connections are tight. Next, attach the shaft to the motor and ensure the coupling is secure. Finally, assemble the cutting mechanism, making sure it is properly aligned and fixed in place.

Throughout the process, use the right tools for each step and check the instructions frequently to avoid mistakes. After assembly, conduct a thorough test to ensure everything is functioning as expected before putting the equipment to use.