In modern machinery, efficient and seamless connections between different components are essential for smooth operation. The attachment system plays a crucial role in ensuring that various tools and equipment can be quickly and securely linked to the main machine. By understanding the structure and functionality of these systems, operators can ensure better performance and longevity.

The key to maintaining these systems lies in knowing the individual elements that make up the connection mechanism. Recognizing each component’s role and how they interact helps with troubleshooting, repair, and overall management. Proper maintenance ensures that the system operates efficiently and minimizes downtime during operations.

With a clear understanding of how these systems function, operators can achieve higher productivity and avoid unnecessary wear and tear. Focusing on the maintenance of these integral parts can drastically improve the machine’s effectiveness, ultimately leading to cost savings and enhanced performance in the long term.

Understanding the Attachment Connection Mechanism

Efficiently attaching tools to heavy machinery is essential for maximizing functionality and flexibility on the job site. The system that enables this swift and secure connection is crucial for improving productivity and reducing downtime. Understanding its design and mechanics can lead to more effective usage and easier troubleshooting.

This connection system consists of multiple components that work together to facilitate seamless transitions between different tools and equipment. Each element plays a significant role in ensuring the connection is both stable and easily operable. Familiarity with the assembly of these elements is vital for proper maintenance and smooth operation.

When properly maintained, the attachment mechanism helps avoid costly delays and enhances machine performance. Operators who understand its inner workings are better equipped to identify issues early and keep the equipment functioning optimally. Regular inspection of these systems also reduces the likelihood of unexpected breakdowns.

Key Components of the Attachment Connection System

To fully grasp how the attachment mechanism functions, it’s important to understand the main components that make up the connection system. These elements work together to ensure stability, ease of use, and durability in heavy machinery applications. Each piece serves a unique purpose and contributes to the overall efficiency of the system.

Structural Elements

The foundational components are designed for strength and durability. These structural pieces support the entire system, ensuring the connection remains secure under heavy loads. Materials used for these components are typically selected for their resistance to wear and stress, extending the service life of the system.

Operational Mechanisms

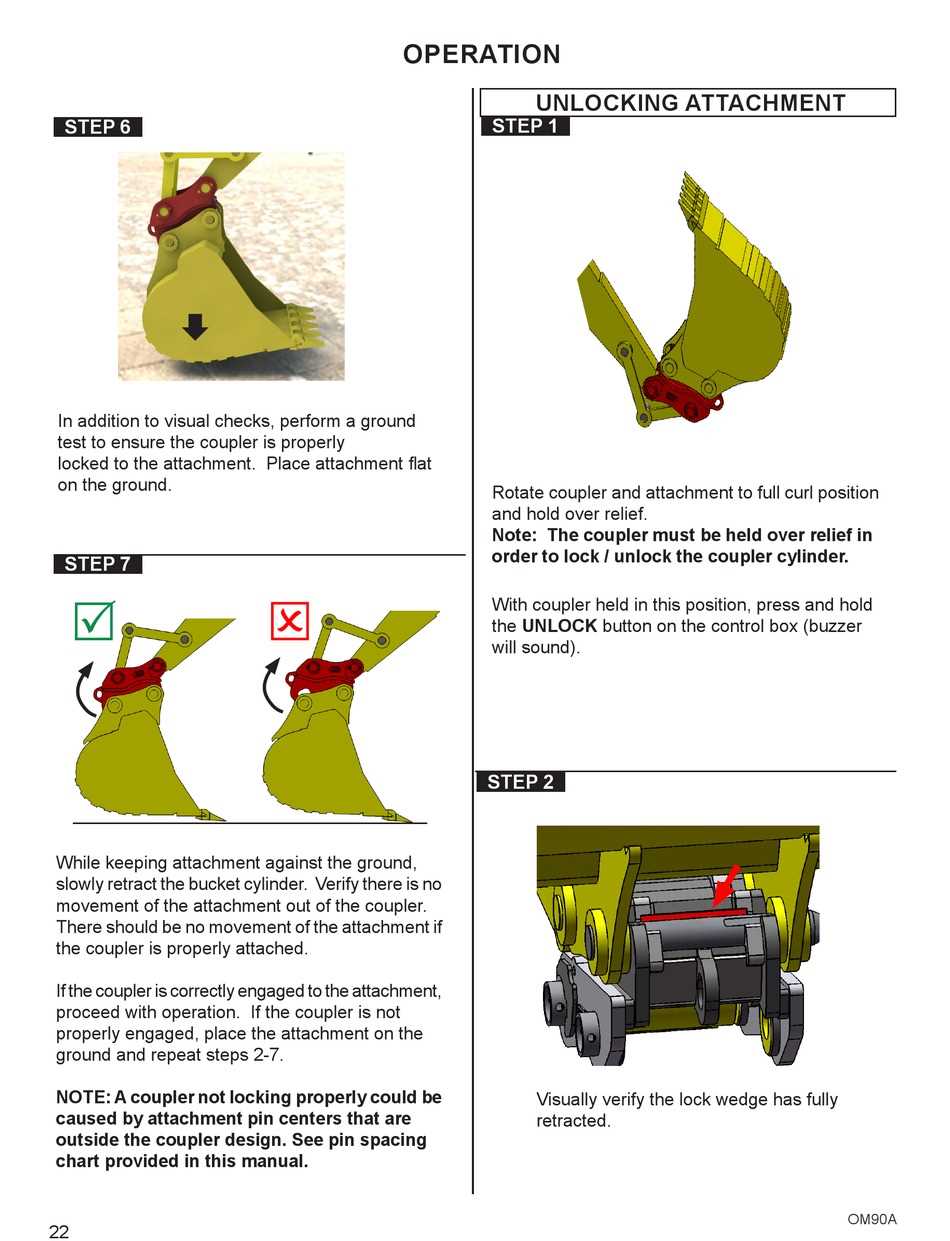

In addition to the structural elements, the operational mechanisms play a vital role in the ease of use and functionality of the connection. These include moving parts that allow the attachment to be quickly secured and released. Understanding their operation is key for maintenance and preventing operational failures.

How to Maintain Attachment System Components

Proper maintenance of the connection system ensures that all components continue to function efficiently and reliably. Regular care can prevent breakdowns and costly repairs, improving the longevity and performance of the machinery. By following a consistent maintenance routine, operators can ensure smooth operations and reduce the likelihood of downtime.

Inspection and Lubrication

Regular inspections are essential for identifying any wear or damage to the system. Pay special attention to moving parts and connection points that experience constant friction. Lubricating these areas not only reduces wear but also helps maintain smooth operation, minimizing the risk of unexpected failures.

Replacing Worn or Damaged Components

Over time, certain elements of the system will wear out or become damaged. Promptly replacing these components ensures the continued efficiency of the mechanism. It’s crucial to use high-quality replacement parts that match the specifications of the original components to maintain optimal performance.