Proper maintenance of your equipment is essential to ensure its longevity and optimal performance. Knowing the individual components and how they fit together allows for easier troubleshooting, repairs, and general upkeep. Whether you’re a professional or a hobbyist, having a clear understanding of how everything works is key to achieving the best results.

Recognizing each element of your tool will help you identify any issues before they become serious problems. Visual references and clear explanations are invaluable for anyone looking to maintain their gear with precision. Familiarity with these components makes it much easier to resolve any malfunctions or replace worn-out sections.

When it comes to repairs, knowing exactly what you’re working with saves time and effort. By becoming acquainted with the key components, you’ll be prepared to tackle any challenge and ensure your tool continues to function smoothly for years to come.

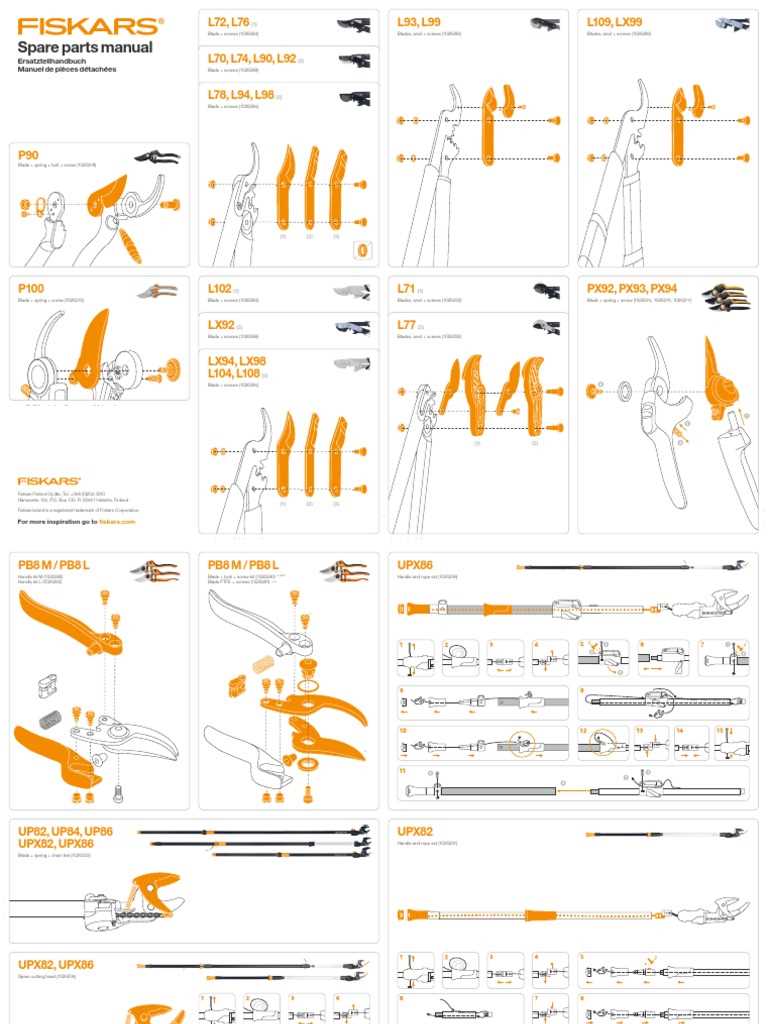

Understanding Fiskars Pole Saw Components

To keep your tool in top condition, it’s essential to understand the individual elements that work together. Each part plays a crucial role in the overall function, and recognizing how they interact allows for better care and efficient repairs. This knowledge also ensures that you can easily identify any issues that may arise during use.

When examining the tool, focus on the key sections that make it operate smoothly. From the handle to the cutting mechanism, each component needs to be properly maintained to ensure long-lasting performance. Knowing where each element fits into the assembly will help you address any wear or damage quickly.

Understanding these components also means knowing which parts are prone to wear and tear. Regular checks and timely replacements will prevent more significant problems, keeping your equipment ready for use at all times. Proper care and attention to each part will ultimately extend the lifespan of your tool.

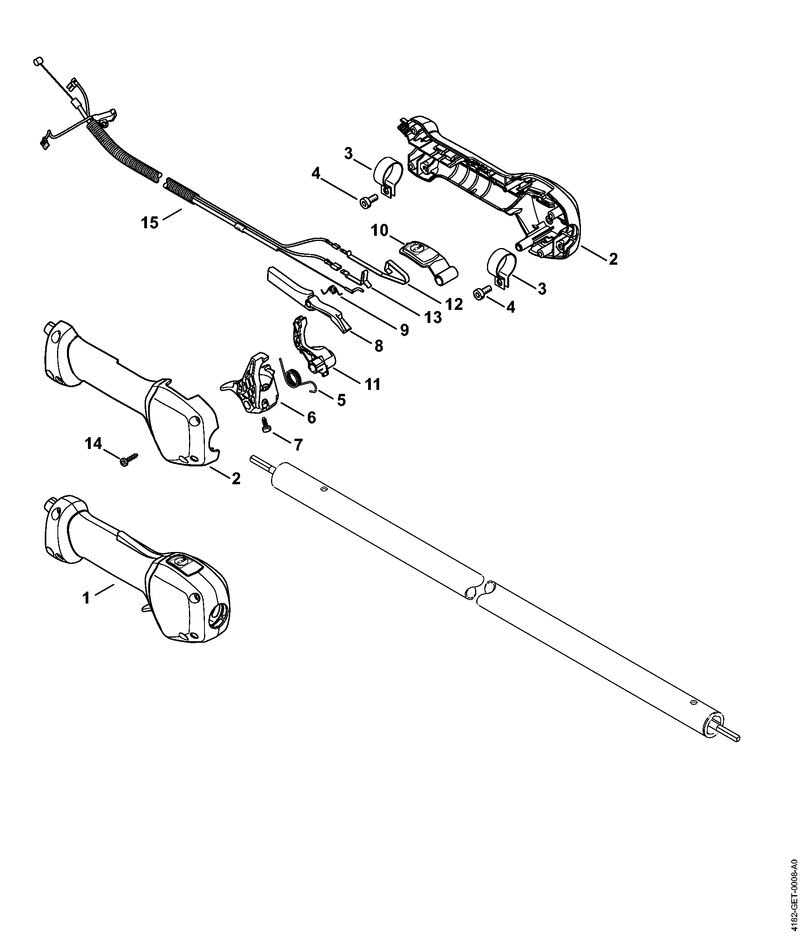

How to Identify Parts in a Diagram

Being able to recognize components in visual representations is crucial for effective repairs and maintenance. A well-labeled diagram provides a clear view of each element, allowing you to understand its role and placement within the tool. By learning to read these illustrations, you can quickly locate the part you need to inspect or replace.

Start by familiarizing yourself with the overall layout of the equipment. Each section should be clearly marked with labels or numbers, corresponding to the individual parts. Pay attention to the shape, size, and function of each component to help differentiate similar items and avoid confusion.

Once you understand the general layout, refer to the provided key or list of names that corresponds to each labeled part. This step ensures that you are correctly identifying the elements in the diagram. With practice, you will become more efficient at navigating these resources, making maintenance tasks quicker and more accurate.

Common Issues with Fiskars Pole Saw Parts

Even with regular use and maintenance, certain elements of your tool may experience wear or malfunction over time. Recognizing common problems early can save you time and money by allowing for quick repairs or part replacements. Understanding which parts are most likely to fail helps in troubleshooting and maintaining the tool’s performance.

Worn or Damaged Cutting Mechanism

The cutting mechanism is often subject to heavy use and can become dull or damaged. Over time, blades or teeth may lose their sharpness, affecting performance. Regular inspection and sharpening can prevent this issue, but if the mechanism shows significant signs of wear, it may need to be replaced entirely.

Loose or Faulty Connections

Parts that are designed to connect various sections of the tool may become loose or weakened due to vibrations during use. This can lead to instability, affecting the overall operation. Tightening screws and ensuring proper assembly after each use can help minimize this issue. In more severe cases, faulty connectors may need to be replaced.