Understanding the intricate details of your power tool can greatly enhance its longevity and performance. Whether you’re an experienced professional or a weekend DIY enthusiast, knowing how to identify and replace individual parts is crucial for efficient maintenance and repair. A comprehensive breakdown of tool components allows you to recognize what to look for when issues arise and how to address them effectively.

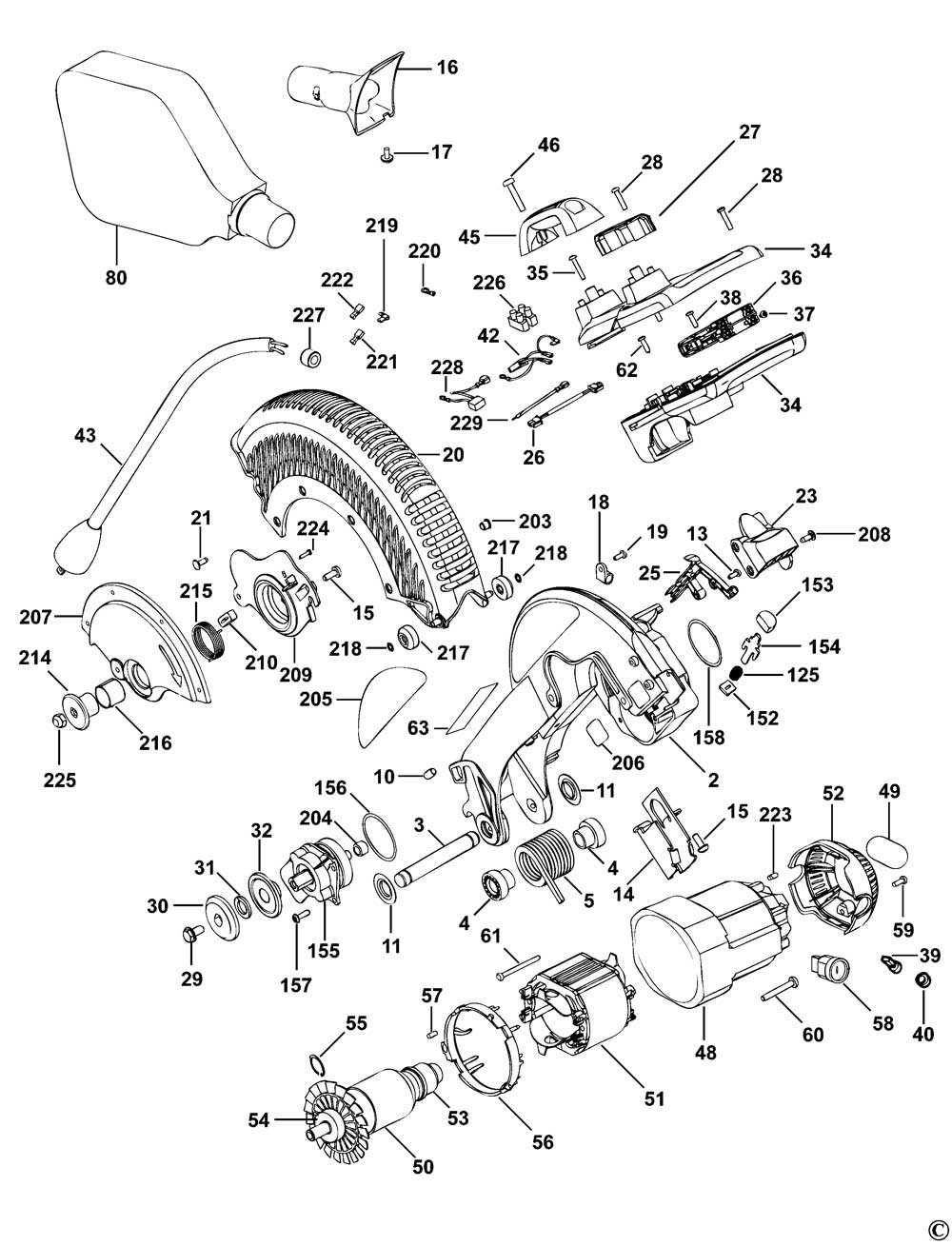

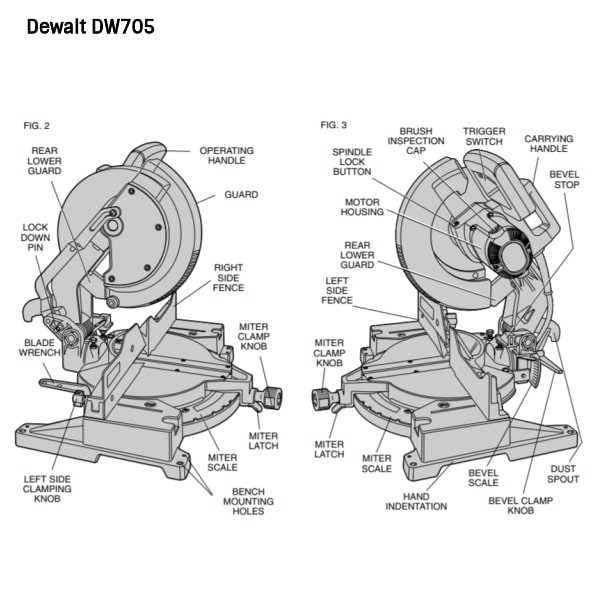

For those looking to replace worn-out or damaged pieces, having a clear visual reference is essential. A well-organized map of each part provides valuable insight, making the process of finding the correct replacement much smoother. This knowledge empowers users to make informed decisions about repairs, reducing downtime and improving productivity.

With the right tools and understanding, maintaining your equipment can be straightforward and cost-effective. The following sections will help you navigate through the essential parts, learn how to locate them, and identify which ones need attention. From simple replacements to more complex repairs, you’ll gain a deeper understanding of how everything works together.

Understanding Tool Component Layout

Having a clear understanding of the layout and arrangement of your tool’s internal and external elements is essential for efficient operation and repair. Each individual piece plays a crucial role in the tool’s overall performance, and recognizing their positions can help you identify issues quickly. A well-structured layout provides insight into the tool’s functionality, making it easier to troubleshoot and replace components when needed.

Key Elements and Their Functions

At the heart of any well-designed tool is a system of interconnected parts that work together to provide the desired outcome. The layout generally starts with the core motor and power system, followed by the supporting components that facilitate movement, precision, and safety. Understanding each of these sections and their specific functions enables better decision-making during repairs or upgrades.

Visual References and Their Importance

One of the most effective ways to comprehend the tool’s structure is by using a visual reference that maps out each part. These references help you quickly identify which components are essential and which may need maintenance. With a clear visual guide, locating the right components for replacement becomes much more straightforward, saving time and reducing the chances of error.

How to Identify Tool Components

Identifying individual components within your tool can be a challenging yet rewarding task. By recognizing each element and understanding its function, you can ensure proper maintenance and avoid unnecessary repairs. Knowing how to spot the signs of wear and which parts require attention is key to extending the tool’s lifespan and maintaining optimal performance.

Step-by-Step Identification Process

Start by examining the tool’s general construction. Look for the main body that houses the power source, followed by the moving parts that enable cutting, drilling, or other functions. Once you’ve familiarized yourself with the structure, identify the smaller elements that might need regular checks, such as gears, switches, and fasteners. Pay close attention to any areas showing signs of damage or wear, as these are the first to be replaced or repaired.

Using Visual Guides for Assistance

To make identification easier, use detailed illustrations or visual guides that break down the tool’s components. These resources help pinpoint each part’s location and offer a clearer understanding of how the pieces fit together. With these guides, you can confidently track down the specific element you need, reducing errors and improving repair accuracy.

Finding Replacement Components for Your Tool

When it’s time to replace a damaged or worn-out part, knowing where to find the right replacement is crucial. Having access to reliable sources ensures that you can restore the tool to its full functionality without unnecessary delays. With the right components, repairs become easier, and you can continue using your equipment effectively for years to come.

Where to Look for Quality Replacements

There are various sources available for purchasing replacement elements, ranging from authorized distributors to third-party suppliers. The key is to find a reputable seller who offers high-quality, durable components that meet the manufacturer’s specifications. Many suppliers provide both original and compatible alternatives, allowing you to choose based on your needs and budget.

Using Identification Guides to Ensure Compatibility

To avoid purchasing the wrong parts, always consult a detailed guide or reference to ensure compatibility. A well-labeled visual guide or a clear parts list can help you confirm that the component you choose will fit properly and function as intended. Double-checking part numbers and specifications will save you time and frustration in the long run.