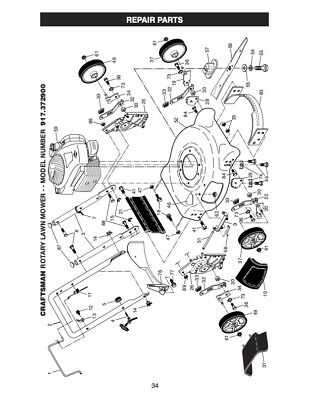

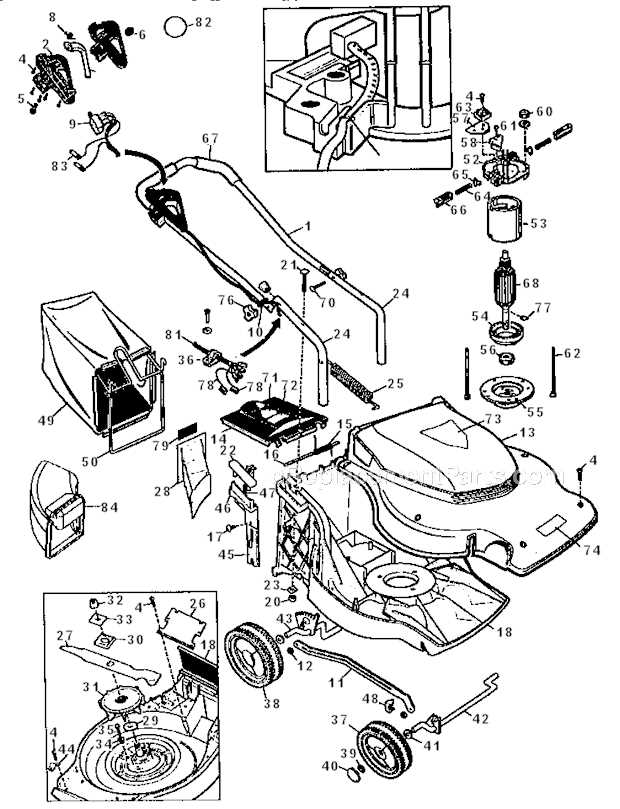

Maintaining lawn equipment requires a thorough understanding of its components. Whether you’re replacing a worn-out piece or simply looking to improve performance, knowing each part’s role is crucial. A clear view of the individual elements will help guide you through the repair or replacement process efficiently.

Identifying key elements in the machinery is the first step toward smooth operation. From the engine to the cutting blades, every component has a specific function, contributing to the overall efficiency. This guide helps you break down each part to make repairs easier.

Knowing your equipment and being able to recognize common issues ensures that you can address problems early. Whether for routine maintenance or tackling unexpected failures, the right knowledge can save time and money, allowing your tools to perform at their best for years to come.

Understanding the Lawn Equipment Components

To maintain and repair your lawn equipment effectively, it is important to understand the different components that work together to achieve optimal performance. Each element serves a distinct purpose, and recognizing how they interact with one another can simplify troubleshooting and replacement tasks.

The key to successful maintenance is knowledge of these essential components. By familiarizing yourself with the roles and connections of each part, you can ensure your equipment runs smoothly, requiring less frequent repairs. Below is a breakdown of some of the critical elements you may encounter.

| Component | Description |

|---|---|

| Engine | The power source of the equipment, responsible for driving the mechanical functions. |

| Blade Assembly | The cutting mechanism that trims the grass, often requiring regular sharpening. |

| Drive Belt | Transfers power from the engine to the wheels, enabling movement. |

| Throttle Control | Regulates the engine’s speed and overall performance. |

| Chassis | The main frame that houses and supports all of the machinery components. |

Understanding the relationship between these elements will help you take the necessary steps for proper upkeep. Whether you’re replacing a specific piece or performing regular maintenance, knowing how everything fits together is essential for efficient operation and longevity.

How to Identify Key Components

Recognizing the main elements of your lawn equipment is essential for proper maintenance and efficient repairs. Each piece serves a specific role, and being able to identify them correctly ensures you can quickly troubleshoot or replace faulty components. Understanding the layout of the system allows you to address issues more effectively, reducing downtime.

Start by examining the engine, which is the heart of the system. It powers all other components, so any issues here can affect the entire operation. Next, locate the cutting mechanism, often a rotating element, that plays a critical role in the functionality of the equipment. Identifying this part allows you to assess wear and determine when it needs attention.

Other key parts to look for include the drive belt, responsible for transmitting power to the wheels, and the control system, which manages the speed and power distribution. By understanding these essential components, you can make informed decisions when it comes to maintenance, ensuring the longevity and performance of your equipment.

Step-by-Step Guide to Replacing Parts

Replacing components in your equipment requires careful planning and execution to ensure everything functions correctly after installation. Whether you’re addressing a worn part or upgrading an essential element, following a methodical approach helps achieve the desired results. This guide will take you through the process of removing and installing new parts efficiently.

Preparation and Safety

Before starting, ensure you have all the necessary tools and replacement parts. Disconnect the power source to prevent any accidents while working. It’s also a good idea to wear protective gloves and eyewear to avoid injury. Lay out your tools in an organized manner, so you can easily access them during the process.

Removing the Old Component

Once you’ve gathered your tools and ensured safety, begin by removing the faulty component. Carefully follow the manufacturer’s instructions for detaching the part. Use appropriate wrenches or screwdrivers to avoid damaging surrounding elements. If necessary, take notes or photos during disassembly to make reassembly easier.

Ensure all connections are properly disconnected before removing the part completely. This step is critical to avoid damaging the equipment’s framework or other elements that rely on the part being replaced.

Installing the New Part

Once the old component is removed, place the new one in position. Make sure the new part aligns with the system’s configuration. Reattach any necessary fasteners, screws, or bolts securely. Double-check the fit to ensure there are no loose connections that could affect the performance.

Final checks involve testing the equipment after the replacement is complete. Run a brief operation to make sure everything works as expected. If any issues arise, revisit the steps to ensure correct installation and functionality.

Ensure Proper Maintenance and Repair

Regular upkeep and timely repairs are essential for extending the lifespan and ensuring the optimal performance of your outdoor equipment. Proper maintenance not only helps prevent unexpected breakdowns but also enhances efficiency and reduces long-term repair costs. By following a structured maintenance schedule, you can address minor issues before they develop into more significant problems.

Maintenance Checklist

Following a consistent routine for upkeep is the first step toward ensuring everything functions correctly. Here are some key tasks to include in your regular maintenance schedule:

- Inspect and clean the engine after each use.

- Check fluid levels and refill when necessary.

- Clean or replace air filters to maintain optimal airflow.

- Lubricate moving parts to prevent friction and wear.

- Sharpen cutting blades regularly for better performance.

Repair Best Practices

If a component becomes damaged or worn out, it is crucial to address the issue promptly to prevent further damage. Follow these steps to ensure proper repairs:

- Identify the problem area and assess the extent of the damage.

- Consult the manufacturer’s guidelines for the correct replacement or repair procedure.

- Use high-quality replacement parts to ensure longevity and performance.

- Test the equipment after repairs to confirm everything operates as expected.

By sticking to a maintenance routine and addressing repairs as soon as possible, you can enjoy reliable performance for many seasons to come.

Common Issues with Lawn Equipment Components

As with any mechanical system, certain components of outdoor machinery are prone to wear and tear over time. Identifying and addressing common issues early on can prevent further damage and ensure the equipment operates smoothly. Understanding typical problems can help you troubleshoot effectively, saving both time and money on repairs.

One frequent issue is the engine performance, which can deteriorate due to clogged filters or low-quality fuel. This often results in poor operation or difficulty starting the equipment. Another common problem is the cutting mechanism, where blades may become dull or damaged, affecting the quality of the cut. Regular inspection of these elements can reveal early signs of wear that can be addressed before they cause more serious issues.

Other common concerns include belt slippage, which can affect the movement of the equipment, and wheel misalignment, leading to uneven operation. Ensuring proper alignment and tightness of all moving parts will minimize these problems. Proper care and maintenance are essential to keep these frequent issues at bay and extend the lifespan of your equipment.