Maintaining outdoor machinery requires a clear understanding of the key elements that contribute to their smooth operation. Properly identifying and replacing worn or damaged components ensures that your machine functions optimally for years. In this section, we delve into the intricate layout of various essential parts and their roles within the system.

Maintenance and repair tasks can be daunting without the right guidance. By breaking down the individual components and their connections, you can easily navigate the restoration process. Whether you’re a novice or an experienced user, having a visual representation of these elements simplifies troubleshooting and repair efforts.

With detailed information about the arrangement and specifications of each component, it becomes easier to identify potential issues early on. Understanding how the different parts interact helps you keep your machine in top condition, reducing the need for costly repairs and minimizing downtime during the maintenance cycle.

Understanding the Key Components of a Lawn Equipment System

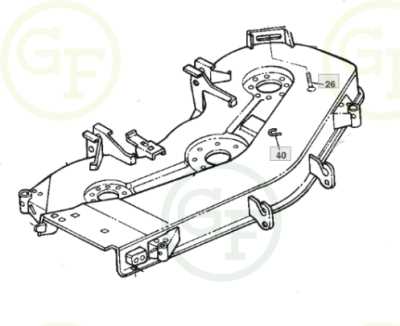

When it comes to maintaining a lawn machine, the understanding of its underlying mechanisms is crucial. One of the most critical sections of any equipment is the set of components responsible for cutting and directing the grass. These elements play a vital role in the efficiency and performance of the entire system. By getting familiar with these components, you can ensure that everything functions smoothly and lasts longer.

Major Components and Their Functions

The structure that supports the cutting elements consists of various interconnected parts, each serving a specific function to facilitate operation. Some of the most important components include:

- Cutting Blades: These are the primary elements responsible for trimming the grass to the desired height. Their sharpness and balance are critical for achieving a clean and even cut.

- Spindles: These mechanisms house the rotating shafts that drive the cutting blades. They must be regularly checked for wear to avoid unnecessary vibration or damage.

- Drive Belt: This part transmits power from the engine to the blades, enabling the cutting motion. It’s essential to keep it tight and free from debris.

- Idler Pulley: Positioned strategically, this component helps maintain tension in the drive belt, ensuring smooth power transfer.

- Grass Chute: This feature directs the clippings away from the machine as it operates, ensuring a clean lawn and preventing buildup of debris around the blades.

Common Issues and Maintenance Tips

Over time, several common problems may arise in the system, but proper care can help avoid or mitigate these issues:

- Uneven Cutting: This could be caused by dull blades or incorrect height settings. Regular sharpening and height adjustments are recommended.

- Excessive Vibration: Vibration issues often stem from worn spindles or an imbalanced cutting assembly. Checking these components regularly can prevent further damage.

- Clogging: Grass buildup around the cutting area can obstruct airflow and reduce efficiency. Periodically cleaning the system after each use is crucial.

- Power Loss: A worn drive belt or faulty idler pulley may cause power loss. Ensure these parts are in good condition and replace them if necessary.

Essential Parts for Lawn Equipment Maintenance

To ensure your outdoor machinery continues to perform efficiently, it is crucial to focus on the most important components that keep the cutting system running smoothly. Regular maintenance of these elements not only prolongs the life of the machine but also improves its overall performance. Understanding the essential pieces involved in the process helps you stay ahead of any potential issues and keep your equipment in top shape.

Key Components to Monitor

Several critical elements within the structure play a role in delivering a smooth and effective operation. Proper care of these components is essential for maintaining the functionality of the system:

- Rotating Blades: These are responsible for cutting grass and require regular inspection for wear and damage. Dull blades may lead to uneven cuts and require sharpening to maintain their efficiency.

- Spindle Assemblies: The spindles are responsible for supporting the rotating blades. Ensure they are free of damage or rust, as these issues can cause imbalance and affect the quality of the cut.

- Drive System: The power transmission system, including pulleys and belts, transfers energy from the engine to the blades. This system should be monitored for wear, fraying, or loosening to prevent power loss or malfunction.

- Airflow System: Components that help direct the clippings away from the blades and clear the area of debris are important for preventing blockages and ensuring efficient operation.

Maintenance Tips for Longevity

Maintaining the longevity of your equipment requires keeping the core components in optimal condition. Here are some essential tips to keep your machine running smoothly:

- Check for Wear: Regularly inspect key components for signs of wear or damage, such as cracks or rust, and replace them as needed.

- Keep Components Clean: Clean the system after every use to prevent grass buildup, dirt, and debris from clogging vital parts.

- Lubricate Moving Parts: Lubrication reduces friction and wear on moving components, ensuring smoother operation and less stress on the system.

- Replace Worn Parts: If you notice that any components are no longer functioning as expected, replace them promptly to avoid further damage or inefficiency.

How to Identify and Replace Components

Proper identification of worn or damaged components is crucial for maintaining outdoor equipment’s performance. Recognizing when a part needs replacing can save both time and money, ensuring the machine runs smoothly. By understanding the key indicators of wear and knowing the steps to replace these parts, you can extend the life of your machine and avoid unnecessary repairs.

Step 1: Identifying Damaged or Worn Parts

Before replacing any component, it’s important to properly assess the condition of each part. Common signs of wear include:

- Visible Cracks or Breaks: Check for any fractures or breaks, especially on components that bear significant load or experience constant motion.

- Excessive Rust or Corrosion: Any metal parts that are significantly rusted or corroded should be replaced immediately to avoid further damage.

- Imbalanced or Worn Blades: A blade that has lost its sharpness or is visibly worn down can cause uneven cutting and should be replaced to ensure clean, efficient operation.

- Loose or Frayed Belts: Belts that are loose or showing signs of fraying should be replaced to maintain proper power transmission and prevent system failure.

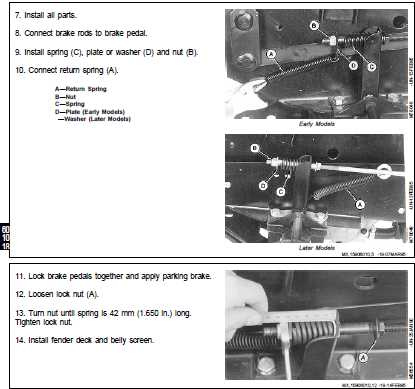

Step 2: Replacing the Components

Once the worn components are identified, follow these general steps to replace them:

- Disconnect the Power: Always ensure the machine is turned off and the power source is disconnected before starting any repair work.

- Remove the Faulty Part: Use the appropriate tools to remove the damaged component, taking care to follow manufacturer instructions if available.

- Install the New Component: Position the new part correctly and securely, ensuring it fits properly and aligns with the rest of the system.

- Test the Machine: After replacing the part, test the machine to ensure everything is functioning correctly. Check for any unusual noises or issues during operation.