When maintaining or repairing machinery, understanding the layout and function of its key elements is crucial. For operators and technicians, having a clear visual representation of each part’s placement and connection ensures accuracy and efficiency during maintenance. Whether you’re troubleshooting an issue or simply replacing worn components, a detailed guide simplifies the process.

Accurate identification of parts can prevent costly mistakes, minimize downtime, and help achieve better results. Familiarity with the individual elements of the system can make a significant difference in how well the equipment performs over time. This is especially important when dealing with complex mechanical systems that require precision and attention to detail.

Using such a detailed schematic can greatly enhance your ability to perform repairs or upgrades. Proper understanding not only saves time but also ensures that each task is completed correctly, maintaining the performance and longevity of your machine. It’s an essential tool for anyone involved in the upkeep of heavy equipment.

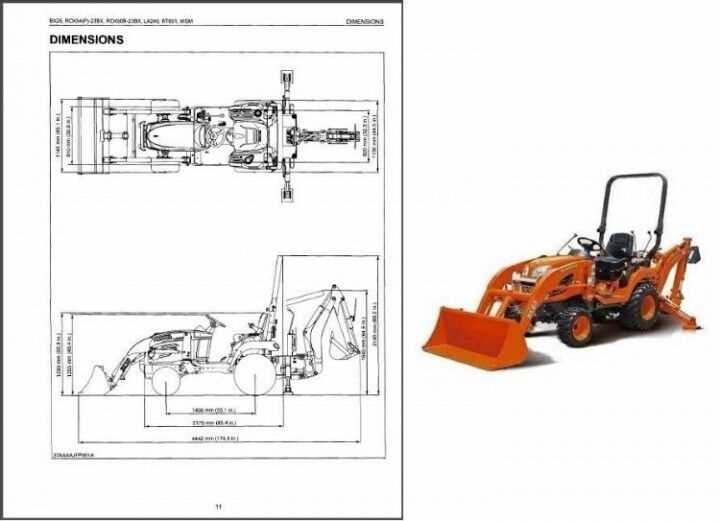

Kubota BX25 Parts Breakdown

Understanding the internal structure of any machinery is essential for efficient operation and maintenance. Knowing the layout and functions of key elements allows for smoother repairs, replacement, and upgrades. Each component plays a specific role, and having a comprehensive understanding of these parts ensures everything works in harmony. A thorough breakdown helps in identifying where issues might arise and which parts are crucial for the machine’s performance.

From the engine and transmission systems to the hydraulic components and steering, every section has a specific set of pieces that contribute to its overall functionality. Each part’s design is optimized to work with others, and recognizing their interdependence can make troubleshooting much easier. For operators and repair technicians, visualizing how the various elements connect is crucial to performing effective repairs and maintenance.

By having access to a well-detailed schematic of the system, users can quickly locate and identify any faulty or worn-out parts. This type of breakdown ensures that you can stay ahead of potential issues and maintain optimal performance. A structured view of the system’s components also helps prevent errors during the repair process, reducing downtime and minimizing costs associated with repairs or replacements.

Identifying Key Components for Repair

When it comes to maintaining machinery, knowing which elements need attention is the first step in ensuring longevity and reliability. Understanding which components are most susceptible to wear or damage allows technicians to prioritize repairs and avoid unnecessary downtime. Proper identification of critical parts is essential for minimizing costly mistakes and ensuring that the right replacements are made.

Locating the essential elements such as the engine, hydraulic system, and drive components is crucial. These areas typically experience the most stress and are often the first to show signs of wear. Regular inspection of these parts helps catch potential issues early, preventing more significant failures down the line. Familiarity with the function of each component also allows for quicker troubleshooting, as issues can often be traced back to a specific area.

Proactive identification of key pieces during routine checks will ensure that the equipment runs smoothly and efficiently. By knowing where to look and what to check, you can avoid lengthy delays and disruptions in operations. This focused approach to maintenance not only extends the life of the machine but also ensures that it continues to perform at its best under all conditions.

How to Use the Parts Diagram Effectively

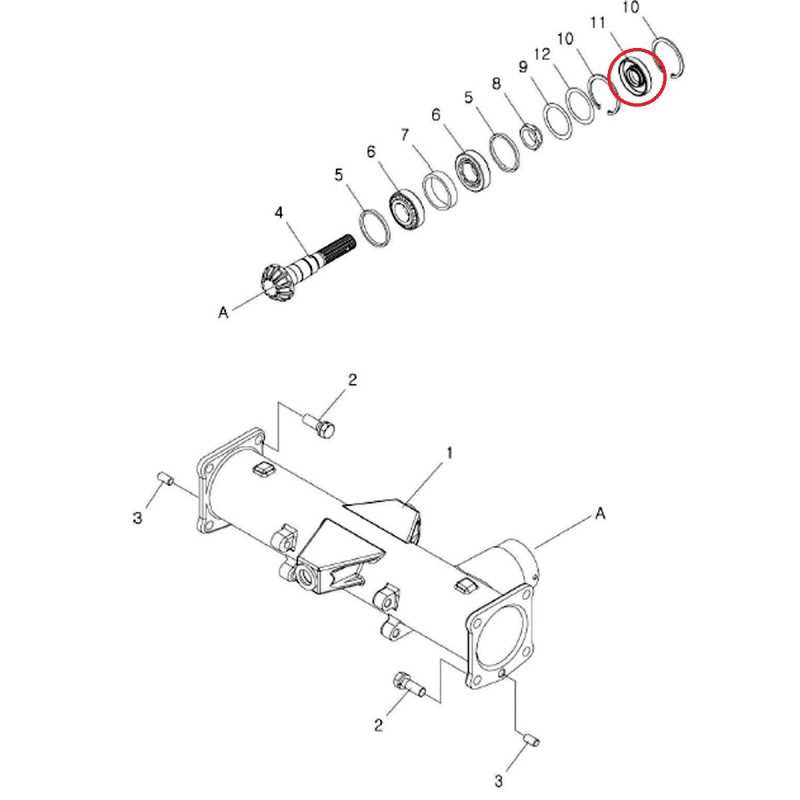

Using a visual reference for mechanical components is an essential skill for anyone working with heavy equipment. It allows for quick identification of parts, streamlines repairs, and helps ensure accurate reassembly. To make the most of these visual tools, understanding how to read and interpret the images correctly is crucial. Following a systematic approach can save time, reduce errors, and improve the overall efficiency of maintenance tasks.

Understand the Structure

Before diving into the specifics, it’s important to familiarize yourself with the overall layout. A well-organized schematic will often be divided into sections that represent different systems or areas of the machine. Knowing how to navigate these sections quickly will help you pinpoint where to focus your attention when an issue arises. Pay close attention to labels, numbers, and reference points that link to detailed information about each part.

Follow Step-by-Step Instructions

Once you’ve identified the relevant section or component, it’s time to follow the steps outlined in the manual or guide. Many references provide clear, sequential instructions for disassembly or reassembly, making the process more straightforward. By adhering to these steps carefully, you ensure that each part is handled in the correct order and that no pieces are overlooked.