When it comes to maintaining your outdoor equipment, knowing the structure and functionality of its components is essential. Understanding how each part fits together and works will not only help you diagnose issues but also guide you in performing repairs efficiently. Properly identifying the key elements is crucial for keeping your tool running smoothly for years to come.

In this section, we’ll explore the internal setup of a popular machine designed for cutting and trimming tasks. You’ll learn to recognize the crucial elements that drive the equipment’s performance. Armed with this knowledge, you’ll be able to pinpoint problems, perform routine checks, and ensure longevity with minimal hassle.

By using clear visual aids and step-by-step instructions, even the most complex systems will become easy to comprehend. Gaining an understanding of these components empowers you to take charge of repairs and reduces reliance on external services, saving both time and money. The next step is to dive into each section for a detailed look at the functionality and maintenance of your equipment.

Understanding Essential Tool Components

To effectively maintain and repair any cutting tool, it’s crucial to understand the key elements that work together to ensure smooth operation. Each component plays a specific role in powering, controlling, and maintaining the overall function of the equipment. Having a clear grasp of these parts enables you to identify issues early, perform repairs, and keep the tool in top shape.

The internal mechanism of such a tool relies on a combination of systems, including the engine, fuel delivery, ignition system, and safety features. Engines provide the necessary power, while the fuel system ensures proper combustion. The ignition system controls the spark timing, and the cutting mechanism ensures precise performance. Each of these systems must work in harmony for optimal functionality.

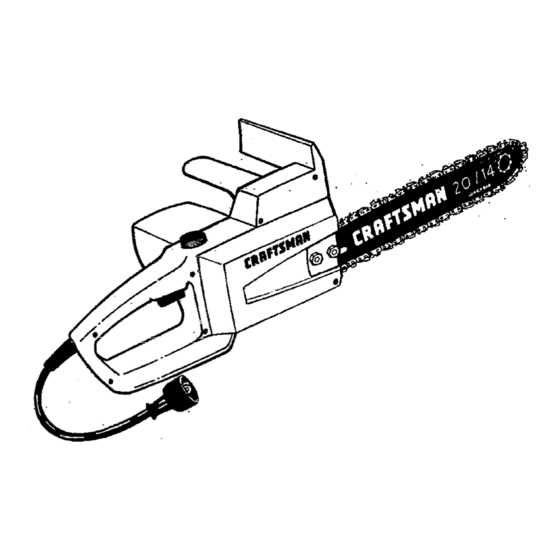

To identify problems and perform necessary maintenance, becoming familiar with the layout of each individual component is essential. Having access to a detailed representation of these components allows for accurate troubleshooting and quicker fixes. Understanding the connections between these parts ensures that you can take proactive steps to preserve the tool’s lifespan and enhance its performance.

Identifying Key Parts for Easy Maintenance

Proper upkeep of any tool requires the ability to quickly recognize and assess the key components that impact its performance. By familiarizing yourself with the essential parts, you can make routine inspections, identify potential issues, and address them before they escalate. Understanding these vital pieces is the first step towards easy and effective maintenance.

Engine and Power System

The engine is the heart of the tool, providing the necessary power to drive its functions. Regular checks on the engine components, such as the fuel system, air filter, and spark plug, ensure that the tool starts easily and runs efficiently. A clean, well-maintained engine can significantly extend the lifespan of the equipment.

Cutting Mechanism and Safety Features

The cutting mechanism, including the chain and bar, is integral to the tool’s primary function. Ensuring that the chain is sharp and the bar is aligned properly will maintain cutting precision. Additionally, safety features such as the brake and clutch system must be regularly checked to prevent accidents and ensure safe operation.

Repair Tips Using the Parts Diagram

Having a visual guide to the internal components of your equipment can make repairs easier and more precise. With a detailed representation of each element, it becomes possible to identify faulty parts and understand how they connect to one another. This approach helps you troubleshoot more effectively and ensures that you address the right issues during repairs.

When performing repairs, start by locating the malfunctioning component on the visual guide. For example, if the tool isn’t starting, check the ignition system and fuel delivery. If the engine doesn’t seem to be running smoothly, focus on the spark plug or air filter. Labeling components as you go can also make reassembly faster and more accurate.

Pay close attention to wear and tear on the critical systems, such as the cutting mechanism or safety features. Regular maintenance helps avoid major issues by addressing small problems before they escalate. By following the visual guide step-by-step, you can ensure that your equipment remains in top condition for longer periods, saving you both time and money in the long run.