Understanding the layout of essential tractor elements is crucial for effective maintenance and repair. A clear and structured representation of each individual part provides valuable insights into how they interconnect and function together. This section is designed to guide you through the various components that make up the machinery, helping you to identify and address potential issues with ease.

In-depth knowledge of each segment, from the engine to the drive system, allows for efficient troubleshooting and ensures that all parts are in optimal working condition. Whether you’re performing routine checks or tackling more advanced repairs, this guide will provide the necessary resources to navigate and manage the tractor’s internal system.

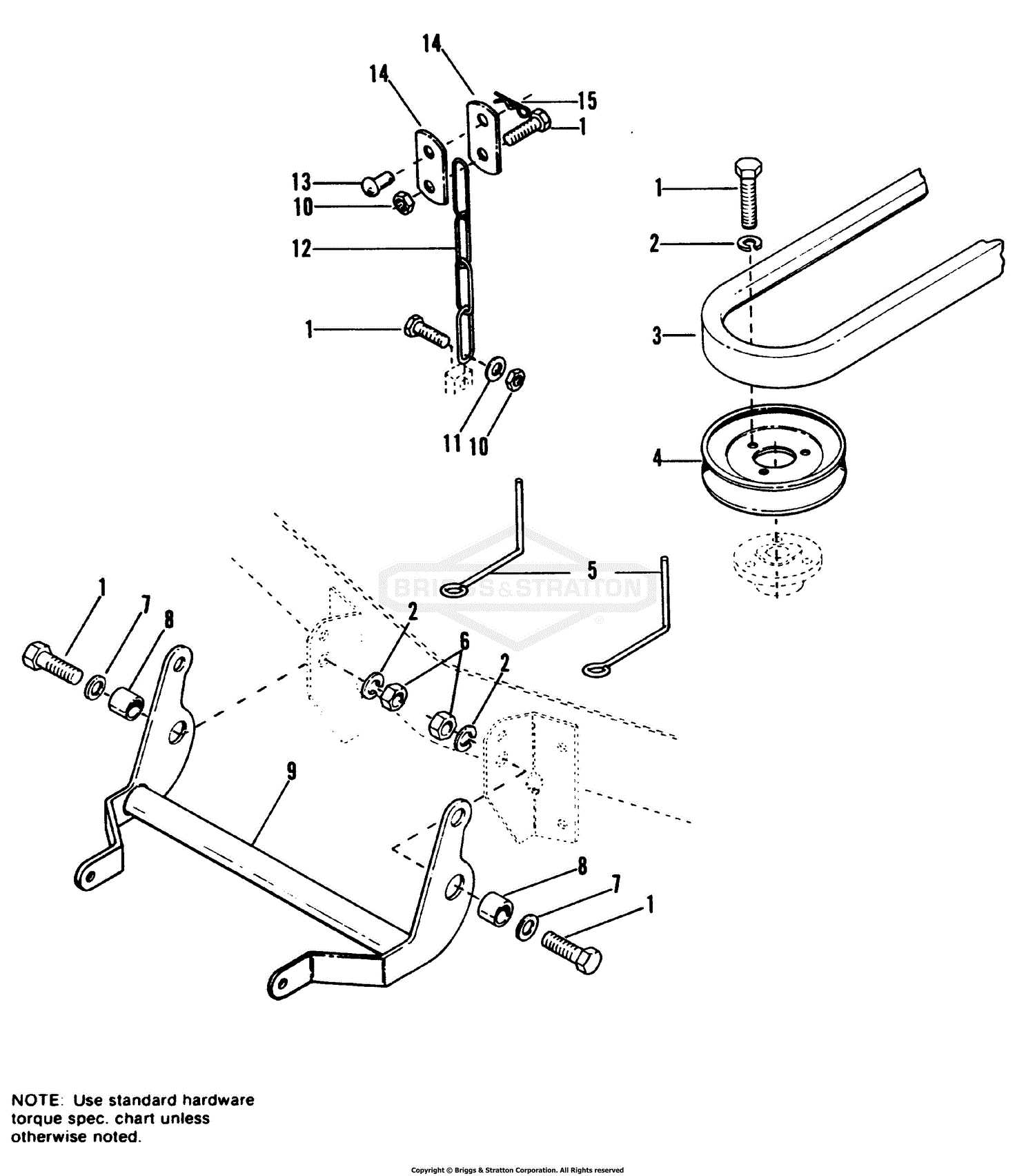

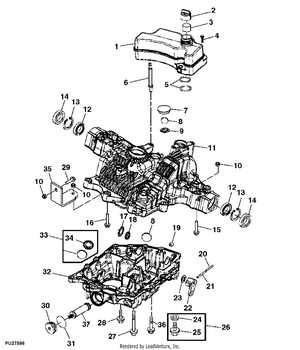

By utilizing detailed schematics, users can gain a better understanding of how each part contributes to the overall performance. This clarity is essential for achieving long-term durability and maintaining the efficiency of your equipment.

Understanding the Tractor Layout

Getting to know the configuration of a machine is essential for anyone looking to maintain or repair it efficiently. By understanding how each major system interacts, users can ensure smooth operation and quickly diagnose issues when they arise. This section focuses on breaking down the various sections and their specific functions within the vehicle, from the engine to the transmission and other key elements.

The layout offers a structured approach to identifying where each component is located and how it contributes to the overall functionality. Recognizing the relationship between individual systems helps in making informed decisions about maintenance and repairs, ensuring that all aspects of the vehicle are running optimally.

By examining the setup in detail, users gain the knowledge needed to understand how changes in one area may affect others, providing a deeper insight into troubleshooting and preventive care. This overview serves as a foundation for anyone looking to extend the life and performance of their machine.

Identifying Key Components for Repair

Understanding the crucial elements of any machine is vital for addressing maintenance needs and conducting effective repairs. By recognizing the most critical components, you can prevent more significant issues down the line and ensure smoother operations. This section will focus on identifying the essential systems that require attention during upkeep and repair procedures.

Engine and Powertrain Overview

The engine and powertrain are the heart of the machinery, and any malfunction in these systems can lead to serious performance issues. Ensuring the engine runs efficiently involves checking components such as the fuel system, spark plugs, and air filters. Proper functioning of the powertrain, including the transmission and drive belts, is equally important for optimal performance.

Steering and Suspension Systems

The steering and suspension systems play a crucial role in the overall maneuverability and stability of the equipment. Identifying wear or damage in parts like the steering column, axles, and shock absorbers is essential for maintaining safe operation. Regular inspections of these components help to avoid mishaps and ensure the machine’s response remains reliable.

How to Use the System Layout Effectively

Utilizing an accurate system layout is key to ensuring that maintenance and repairs are done properly. With the right approach, the layout can serve as a powerful tool for locating, identifying, and understanding the connection between different components. This section will guide you through how to leverage the layout for more efficient troubleshooting and part replacement.

Reading and Interpreting the Layout

Understanding how to read and interpret the layout is the first step in using it effectively. Each section and component is labeled in a way that allows you to quickly locate any area of interest. Pay close attention to the numbering and corresponding references to avoid confusion when searching for specific parts or systems.

Locating and Replacing Faulty Components

Once you’ve identified the faulty component, the next step is to determine its position within the system. With the layout in hand, you can easily pinpoint the exact location, ensuring you can replace or repair it with minimal disruption. Using the layout also helps to prevent errors by guiding you through the proper steps for disassembly and reassembly.